This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

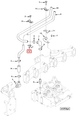

The Cummins 3931541 Tube Clamp is a component designed for use in commercial truck maintenance and operation. It serves a specific function within the truck’s systems, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and significance is important for maintaining the truck’s performance and longevity.

Basic Concepts of Tube Clamps

Tube clamps are devices used to secure and connect tubing systems in various automotive and industrial applications. They function by providing a tight seal around the tubing, ensuring that fluids or gases are transported efficiently without leaks. Tube clamps come in different designs and materials, each suited to specific applications based on the environment and the type of tubing used 1.

Purpose of the Cummins 3931541 Tube Clamp

The Cummins 3931541 Tube Clamp is utilized in commercial trucks to secure tubing connections in various systems, such as the fuel, coolant, and hydraulic systems. Its role is to maintain a secure and leak-free connection, which is vital for the proper operation of these systems. The clamp ensures that the tubing remains firmly in place under varying conditions, including vibrations and temperature changes, which are common in truck operations 2.

Key Features

The Cummins 3931541 Tube Clamp is constructed with materials that offer durability and resistance to corrosion, making it suitable for the demanding conditions found in commercial truck environments. Its design includes a clamping mechanism that allows for easy adjustment and a secure fit around the tubing. Unique attributes of this clamp may include a robust construction that enhances its performance and longevity.

Benefits of Using the Cummins 3931541 Tube Clamp

Using the Cummins 3931541 Tube Clamp offers several advantages. It provides improved reliability in tubing connections, which is crucial for the safe and efficient operation of commercial trucks. The clamp’s design facilitates ease of installation, reducing downtime during maintenance. Additionally, its durability contributes to maintenance efficiency by minimizing the need for frequent replacements 3.

Installation Process

Installing the Cummins 3931541 Tube Clamp requires following a step-by-step process to ensure a secure fit. This includes preparing the tubing by cleaning and inspecting it for any damage, positioning the clamp around the tubing, and tightening it to the manufacturer’s specifications. Using the appropriate tools and following best practices during installation is important to achieve the desired performance and longevity of the clamp.

Troubleshooting Common Issues

Common issues with tube clamps, such as leaks or improper clamping, can often be addressed through troubleshooting. This may involve inspecting the clamp and tubing for signs of wear or damage, ensuring the clamp is tightened correctly, and verifying that the tubing is compatible with the clamp. Addressing these issues promptly can help maintain the integrity of the truck’s systems.

Maintenance Tips

Regular maintenance of the Cummins 3931541 Tube Clamp is important to prolong its lifespan and ensure continued reliable performance. This includes routine inspections for signs of wear or corrosion, cleaning the clamp and tubing as needed, and replacing the clamp if it shows signs of significant wear or damage. Adhering to these maintenance practices can help prevent unexpected failures and ensure the clamp continues to perform its intended function effectively.

Safety Considerations

When installing, maintaining, or troubleshooting the Cummins 3931541 Tube Clamp, it is important to observe safety protocols and precautions. This includes wearing appropriate personal protective equipment, ensuring the truck is safely supported during maintenance, and following all manufacturer guidelines for the clamp’s use. These safety measures help protect both the user and the component, ensuring a safe working environment and maintaining the integrity of the truck’s systems.

Cummins Overview

Cummins Inc. is a well-established company in the commercial vehicle industry, known for its wide range of products, including engines, filtration systems, and components like the 3931541 Tube Clamp. With a history of innovation and a commitment to quality, Cummins has built a reputation for reliability and performance. This background underscores the quality and dependability of the Cummins 3931541 Tube Clamp in commercial truck applications.

Tube Clamp 3931541 Compatibility with Cummins Engines

The Tube Clamp 3931541, manufactured by Cummins, is a component designed to secure and stabilize various tubes and hoses within the engine’s system. This part is engineered to fit seamlessly with several Cummins engine models, ensuring optimal performance and reliability.

Compatibility with Specific Engine Models

-

6B5.9 and B5.9 G Engines: The Tube Clamp 3931541 is specifically designed to fit the 6B5.9 and B5.9 G engines. These engines are known for their robust construction and efficiency. The clamp ensures that all connected tubes and hoses maintain their integrity under the operational stresses of these engines.

-

ISB CM550 and ISB CM850 Engines: For the ISB CM550 and ISB CM850 engines, the Tube Clamp 3931541 is equally essential. These engines are part of Cummins’ Intelligent Systems for Better Performance (ISB) series, which emphasizes advanced technology and performance. The clamp’s design allows it to effectively secure tubes and hoses, contributing to the overall efficiency and longevity of these engines.

Grouping of Engine Models

When considering the ISB series engines, the Tube Clamp 3931541 is versatile enough to be used across both the ISB CM550 and ISB CM850 models. This grouping highlights the clamp’s adaptability and its ability to meet the demands of different engine sizes and specifications within the same series.

The Tube Clamp 3931541’s compatibility with these engines underscores its importance in maintaining the structural integrity of the engine’s tubing system. By ensuring that all connections are secure, this part contributes to the overall reliability and performance of the engines it is used with.

Role of Part 3931541 Tube Clamp in Engine Systems

The part 3931541 Tube Clamp is instrumental in ensuring the secure and efficient connection of various fluid-carrying tubes within engine systems. Its application spans across multiple components, each playing a distinct role in the overall functionality and performance of the engine.

Block Vent Plumbing

In the block vent plumbing system, the Tube Clamp ensures that the vent tubes are firmly attached to the engine block. This connection is essential for maintaining proper ventilation, which helps in regulating pressure within the engine block and preventing the buildup of harmful gases.

Cooler

When integrated with the cooler system, the Tube Clamp secures the tubes that transport fluids to and from the cooler. This ensures that the cooling process is efficient, maintaining optimal operating temperatures for the engine and other components.

Torque Converter Oil

For the torque converter oil system, the Tube Clamp plays a key role in securing the tubes that carry oil to and from the torque converter. This ensures a consistent and reliable flow of oil, which is vital for the smooth operation and longevity of the torque converter.

Exhaust Recirculation Water

In systems involving exhaust recirculation water, the Tube Clamp is used to secure the tubes that transport water for recirculation purposes. This helps in reducing emissions and improving the overall efficiency of the engine by ensuring that the water is recirculated effectively.

Vent

The Tube Clamp is also utilized in vent systems to secure tubes that allow for the release of pressure or gases from various engine components. This is important for maintaining a balanced internal environment within the engine.

Engine Coolant

Finally, in the engine coolant system, the Tube Clamp ensures that the tubes carrying coolant are securely attached. This is essential for maintaining the engine’s temperature within safe operating limits, preventing overheating, and ensuring the longevity of engine components.

Conclusion

The Cummins 3931541 Tube Clamp plays a vital role in the maintenance and operation of commercial trucks by ensuring secure and leak-free connections in various engine systems. Its durability, ease of installation, and compatibility with specific Cummins engine models make it a reliable component for maintaining the efficiency and reliability of commercial vehicles.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.