This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

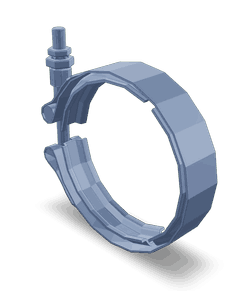

The V Band Clamp 3935338 is a specialized component manufactured by Cummins, a prominent entity in the commercial truck industry. This clamp is designed for use in commercial trucks, where it plays a significant role in the exhaust and intake systems. Cummins is renowned for its high-quality engine components, and the V Band Clamp 3935338 is no exception, offering reliable performance and ease of use.

Basic Concepts of V Band Clamps

V Band Clamps are a type of fastening device used to secure pipes and tubing in various automotive and industrial applications. They consist of a band that wraps around the pipe and a shell that clamps down on the band, creating a secure seal. V Band Clamps are favored for their quick installation and removal capabilities, as well as their ability to provide a leak-proof connection 1.

Purpose of V Band Clamp 3935338

The V Band Clamp 3935338 is integral to the operation of a truck’s exhaust and intake systems. It ensures a tight seal between components, which is vital for maintaining the efficiency and performance of the engine. By securing the connections in these systems, the clamp helps to prevent leaks that could lead to a loss of power or increased emissions 2.

Key Features

The V Band Clamp 3935338 boasts several key features that enhance its performance. It is constructed from durable materials that can withstand the high temperatures and pressures found in truck exhaust systems. The design of the clamp allows for easy installation and removal, which is particularly beneficial during maintenance or repair procedures. Additionally, the clamp’s unique attributes, such as its corrosion-resistant properties, contribute to its longevity and reliability.

Benefits of Using V Band Clamps

V Band Clamps offer several advantages over traditional clamping methods. They are known for their ease of installation, which can significantly reduce downtime during maintenance. The reliability of V Band Clamps is another key benefit, as they provide a secure and leak-proof connection that is less likely to fail under stress. Furthermore, the maintenance requirements for V Band Clamps are generally lower than those for other types of clamps, making them a cost-effective choice for commercial truck applications.

Installation Process

Installing the V Band Clamp 3935338 requires attention to detail to ensure a proper seal. The process involves positioning the clamp around the pipe, aligning it with the mating surfaces, and then tightening the shell until the desired torque is achieved. It is important to follow the manufacturer’s guidelines for torque specifications to avoid over-tightening, which can damage the clamp or the pipe. Additionally, ensuring that the surfaces are clean and free of debris before installation will help to achieve a leak-proof seal.

Troubleshooting Common Issues

Common issues with V Band Clamps can include leaks, difficulty in installation or removal, and clamp failure. Leaks may be caused by improper installation, damage to the clamp, or corrosion. To address leaks, it is important to inspect the clamp for damage and ensure that it is properly installed. Difficulty in installation or removal may be due to corrosion or the use of incorrect tools. Regular inspection and maintenance can help to prevent these issues. Clamp failure can occur due to material fatigue or excessive stress; replacing the clamp with a new one is typically the solution.

Maintenance Tips

To ensure the longevity and optimal performance of the V Band Clamp 3935338, regular maintenance is recommended. This includes inspecting the clamp for signs of wear or damage, ensuring that the surfaces remain clean and free of debris, and verifying that the clamp is properly torqued. Additionally, it is important to monitor the condition of the exhaust and intake systems to identify any potential issues that may affect the clamp’s performance.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing high-quality, reliable components. The company’s product range includes engines, powertrain components, and aftermarket parts, all of which are designed to meet the demanding requirements of commercial applications.

Applications of V Band Clamp 3935338

The V Band Clamp 3935338, manufactured by Cummins, is a versatile component designed to fit a variety of Cummins engine models. This clamp is essential for creating a secure seal in various applications, ensuring that connections remain tight and leak-free.

For the 4B3.9 and 6B5.9 engines, the V Band Clamp is used in applications where a robust sealing solution is required, such as in exhaust systems or other fluid transfer lines.

In the B5.6 CM2670 B152B and B5.9 GAS PLUS CM556 engines, this clamp is often utilized in high-pressure environments, providing a reliable seal that can withstand significant stress and temperature variations.

For the B6.7 CM2670 B153B engine, the V Band Clamp is a critical component in maintaining the integrity of connections in the engine’s cooling system, ensuring that coolant flows efficiently without leaks.

The ISB5.9 CM2880 B110, ISB5.9 CM2880 B140, and ISB5.9 CM2880 B149 engines also benefit from this clamp, particularly in applications where precise sealing is necessary to prevent fluid or gas leaks, enhancing the overall performance and reliability of the engine.

In the ISB5.9G CM2180 engine, the V Band Clamp is used in various sealing applications, providing a dependable solution for maintaining system integrity.

For the ISBE4 CM850 engine, this clamp is essential in ensuring that all connections are secure, which is crucial for the engine’s operation and longevity.

Lastly, in the QSB7 CM2880 B117 engine, the V Band Clamp is used in critical sealing applications, ensuring that the engine operates efficiently and reliably by preventing leaks and maintaining system pressure.

Role of Part 3935338 V Band Clamp in Engine Systems

The part 3935338 V Band Clamp is instrumental in ensuring secure and efficient connections within various engine systems. It is specifically designed to facilitate robust connections in several key areas:

Air Intake System

In the air intake system, the V Band Clamp is used to connect the air filter housing to the intake manifold. This connection is vital for maintaining the integrity of the air pathway, ensuring that unfiltered air does not enter the engine, which could lead to performance issues and increased wear on engine components.

Exhaust System

Within the exhaust system, the V Band Clamp plays a significant role in connecting the exhaust manifold to the catalytic converter, as well as linking the catalytic converter to the exhaust outlet. These connections are essential for maintaining the efficiency of the exhaust flow, reducing backpressure, and ensuring that emissions are properly managed.

Turbocharger Connections

For turbocharged engines, the V Band Clamp is used to connect the turbocharger to both the intake and exhaust systems. On the intake side, it ensures a tight seal between the turbocharger and the intake manifold, which is necessary for optimal airflow into the engine. On the exhaust side, it connects the turbocharger to the exhaust manifold, facilitating efficient exhaust gas recirculation and enhancing turbocharger performance.

General Connections

Beyond specific systems, the V Band Clamp is also employed in various general connections throughout the engine bay. These include linking different sections of the intake and exhaust pipes, as well as securing connections in the emissions control system. Each of these applications relies on the clamp’s ability to provide a leak-free seal, which is paramount for the overall performance and reliability of the engine.

Conclusion

The V Band Clamp 3935338 by Cummins is a critical component in the maintenance and operation of commercial truck engines. Its design and features make it an effective solution for ensuring secure and leak-proof connections in various engine systems. Regular maintenance and proper installation are key to maximizing the performance and longevity of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.