This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

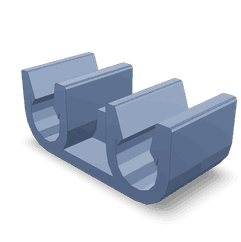

Tube clamps are critical components in commercial truck engines, ensuring secure and efficient connections of various tubes and hoses. Among these, the Cummins 3947336 Tube Clamp is notable for its robust design and essential role in maintaining engine performance. This article explores the function, integration, and maintenance of this Cummins part, highlighting its importance in engine systems.

Basic Concepts Related To Tube Clamps

A tube clamp is a mechanical device designed to hold and seal tubes and hoses securely. Its primary function is to create a leak-proof connection that can withstand engine pressures and vibrations. Typically constructed from durable materials like stainless steel, aluminum, or high-strength polymers, tube clamps are chosen for their resistance to corrosion and high temperatures. In commercial trucks, they are vital for connecting fuel lines, coolant hoses, and other fluid pathways, ensuring smooth engine operation 1.

How A Tube Clamp Works

The mechanism of a tube clamp involves a band that wraps around the tube and a tightening mechanism, often a screw or bolt, that compresses the band to create a secure seal. This compression ensures the tube is held firmly in place, containing any fluid without leaks. Proper sealing and pressure retention are critical, as even minor leaks can lead to significant performance issues and potential engine damage. A visual representation would show the band tightening around the tube, creating uniform pressure that holds the connection intact under various operating conditions 2.

Purpose Of The Cummins 3947336 Tube Clamp

The Cummins 3947336 Tube Clamp is designed to maintain the integrity of fluid connections in Cummins engines. It ensures that fuel, coolant, and other essential fluids are delivered efficiently and without interruption. This tube clamp contributes to the overall reliability and performance of commercial trucks by preventing leaks and ensuring optimal fluid pathway operation. Its robust construction and precise engineering make it a cornerstone component in the engine system 3.

Troubleshooting And Maintenance

Common issues with tube clamps include corrosion, wear, and improper installation, which can lead to leaks and reduced engine efficiency. Symptoms may include fluid leaks, engine performance drops, or unusual noises. Troubleshooting involves inspecting the clamp for wear or corrosion, ensuring proper installation and tightening, and replacing it if necessary. Regular maintenance tips include periodic inspections, cleaning the clamp and surrounding areas, and replacing the clamp at recommended intervals to ensure longevity and optimal performance. Regular inspections and timely replacements are crucial for maintaining engine efficiency and preventing costly repairs.

Cummins: A Leader In Engine Manufacturing

Cummins is renowned for its commitment to quality and innovation in engine components. The company’s reputation is built on producing reliable, high-performance engines and components that meet the demanding requirements of commercial trucking. Cummins’ dedication to advancing commercial truck technology is evident in their continuous investment in research and development, ensuring that their products, including the 3947336 Tube Clamp, are at the forefront of engine technology.

Expert Insights And Best Practices

Industry experts emphasize the significance of proper tube clamp maintenance, highlighting that well-maintained clamps are crucial for engine longevity and performance. Best practices for engineers and mechanics include using the correct tools for installation and maintenance, following manufacturer guidelines for torque specifications, and conducting regular inspections. Real-world examples of successful troubleshooting and maintenance procedures often involve proactive measures such as scheduled replacements and the use of high-quality replacement parts to ensure consistency and reliability.

Tube Clamp 3947336 Compatibility with Cummins Engines

The Tube Clamp part number 3947336, manufactured by Cummins, is designed to fit a variety of Cummins engines. This clamp is essential for securing and maintaining the integrity of various tubes and hoses within the engine system. Below is a detailed breakdown of the engines with which this tube clamp is compatible:

ISB Series Engines

- ISB CM2150

- ISB CM850

- ISB/ISD6.7 CM2150 SN

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

ISBE Series Engines

- ISBE CM2150

- ISBE4 CM850

ISC Series Engines

- ISC CM2150

- ISC CM850

ISL Series Engines

- ISL CM2150

- ISL9 CM2150 SN

QSB Series Engines

- QSB5.9 CM850

- QSB6.7 CM2250

- QSB6.7 CM850 (CM2850)

QSC Series Engines

- QSC8.3 CM850 (CM2850)

QSL Series Engines

- QSL8.9 CM2150 L141

- QSL9 CM850 (CM2850)

This tube clamp is engineered to provide a reliable and secure fit across these diverse engine models, ensuring that all connected tubes and hoses are properly fastened and maintained. It is a crucial component for the operational integrity of the engine systems, helping to prevent leaks and maintain system pressure.

Role of Part 3947336 Tube Clamp in Engine Systems

In the intricate network of an engine system, the 3947336 Tube Clamp serves as a vital connector, ensuring the integrity and efficiency of various components. Specifically, this clamp is instrumental in the secure attachment of fuel plumbing lines, which are essential for the delivery of fuel from the tank to the engine.

The Tube Clamp is designed to maintain a tight seal around the fuel lines, preventing any potential leaks that could compromise engine performance or pose safety hazards. Its application extends to the connection points between the fuel lines and the fuel filter, where it ensures that the filtration process is uninterrupted and efficient.

Furthermore, the clamp’s role in the plumbing system is not limited to fuel lines alone. It is also used in general plumbing applications within the engine system, where it secures various hoses and pipes that transport fluids essential for the engine’s operation. This includes coolant lines and other auxiliary fluid pathways that require a secure and leak-free connection.

The effectiveness of the 3947336 Tube Clamp in these applications is a testament to its design, which allows for easy installation and removal while providing a robust connection that can withstand the vibrations and pressures inherent in engine operation. Its use in these systems underscores the importance of reliable component interconnections in maintaining the overall functionality and safety of the engine.

Conclusion

Understanding and maintaining tube clamps, such as the Cummins 3947336, is essential for the longevity and efficiency of commercial trucks. By ensuring secure and leak-proof connections, these components play a critical role in engine performance. Regular maintenance, timely inspections, and the use of high-quality parts are key to preventing issues and ensuring that commercial trucks operate at peak efficiency.

-

Andrew Brown Jr, Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles, National Academy of Sciences, 2010.

↩ -

Vaclav Smil, The History and Impact of Diesel Engines and Gas Turbines, The MIT Press, 2010.

↩ -

Qianfan Xin, Diesel Engine System Design, Woodhead Publishing, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.