This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

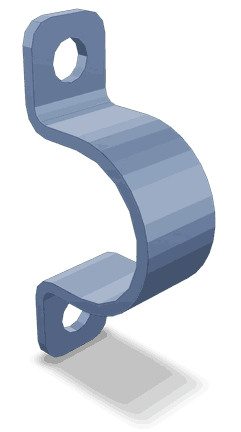

The 3954196 Tube Clamp, manufactured by Cummins, is a component designed for use in commercial truck operations. Cummins, a well-established name in the industry, produces a range of parts and systems that contribute to the efficiency and reliability of heavy-duty vehicles. This Cummins part plays a role in securing various tubing systems within these trucks.

Basic Concepts of Tube Clamps

Tube clamps are mechanical fasteners used to secure tubing in place. They are commonly employed in automotive and industrial applications to ensure that tubing systems remain intact and function correctly. Tube clamps work by compressing the tubing against a saddle or band, creating a secure connection that can withstand vibrations and movements typical in vehicle operations 1.

Purpose of Tube Clamp 3954196 in Truck Operations

In commercial truck operations, the 3954196 Tube Clamp serves to secure tubing in various systems, including fuel lines, hydraulic systems, and exhaust systems. Its application ensures that these critical systems remain connected and function as intended, contributing to the overall performance and safety of the vehicle 2.

Key Features of Tube Clamp 3954196

This part is designed with specific characteristics that enhance its effectiveness and durability. It is constructed from high-quality materials that resist corrosion and wear, ensuring long-term reliability. The clamp features a robust design that provides a strong grip on the tubing, minimizing the risk of disconnection. Additionally, it is engineered to accommodate a range of tubing sizes, offering versatility in application.

Benefits of Using Tube Clamp 3954196

The use of this part offers several advantages. Its design allows for easy installation, reducing downtime during maintenance procedures. The clamp’s reliability ensures that tubing systems remain secure, contributing to the safety and efficiency of truck operations. Furthermore, its durability minimizes the need for frequent replacements, offering cost-effective maintenance benefits.

Installation Process

To install the 3954196 Tube Clamp, first, ensure the tubing is clean and free of debris. Position the clamp over the tubing and align it with the saddle. Use the appropriate tool to tighten the clamp, ensuring even pressure is applied around the tubing. Verify the connection is secure by checking for any gaps or looseness. Proper installation is key to ensuring optimal performance and longevity of the clamp.

Troubleshooting Common Issues

Common issues with tube clamps may include loosening over time due to vibrations or wear. To address these problems, regular inspections are recommended to identify any signs of wear or loosening. If an issue is detected, the clamp should be retightened or replaced as necessary to maintain a secure connection. Additionally, ensuring the clamp is correctly sized for the tubing can prevent many common problems.

Maintenance Tips

Regular inspection and maintenance of the 3954196 Tube Clamp are recommended to prolong its service life and ensure continued reliable performance. Inspect the clamp for signs of corrosion, wear, or damage during routine maintenance checks. Clean the clamp and surrounding areas to remove any debris that could affect its performance. Retighten the clamp if necessary to maintain a secure connection.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and aftermarket parts. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial truck industry. Their product range includes components and systems designed to enhance the performance, efficiency, and durability of heavy-duty vehicles.

Tube Clamp 3954196 Compatibility with Cummins Engines

The 3954196 Tube Clamp, manufactured by Cummins, is a component designed to secure and stabilize various tubes and hoses within the engine system. This part is engineered to fit seamlessly with several Cummins engine models, ensuring a reliable and secure connection.

ISB CM2150 and ISB6.7 CM2250

The 3954196 Tube Clamp is compatible with the ISB CM2150 and ISB6.7 CM2250 engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications. The clamp ensures that all connected tubes and hoses maintain their integrity under high-pressure conditions, preventing leaks and ensuring optimal engine performance.

ISB CM850

Similarly, the ISB CM850 engine also benefits from the use of the 3954196 Tube Clamp. This engine is designed for medium-duty applications, providing a balance between power and efficiency. The clamp’s design allows for easy installation and secure fastening, which is crucial for maintaining the engine’s operational efficiency and longevity.

Application Considerations

When using the 3954196 Tube Clamp with these engines, it is essential to ensure that the clamp is properly aligned and tightened to the manufacturer’s specifications. This will help in achieving the best performance and durability of the engine components. Regular inspection and maintenance of the clamp are also recommended to prevent any potential failures or leaks.

Role of Part 3954196 Tube Clamp in Engine Systems

The 3954196 Tube Clamp is a component in securing and maintaining the integrity of various engine system connections. In plumbing applications, this clamp ensures that fluid lines remain firmly attached, preventing leaks and maintaining consistent fluid pressure. This is particularly important in fuel delivery systems where any disruption can lead to engine performance issues 3.

In exhaust recirculation (EGR) systems, the 3954196 Tube Clamp plays a role by securing the recirculation tubes. This ensures that exhaust gases are effectively redirected back into the engine’s intake tract, which helps in reducing nitrogen oxides (NOx) emissions. A secure connection is vital to maintain the efficiency of the EGR system and to ensure that the recirculated gases do not escape, which could otherwise lead to increased emissions and decreased engine performance.

Additionally, in air intake systems, the 3954196 Tube Clamp is used to secure air intake hoses. This ensures a steady and uninterrupted flow of air into the engine, which is necessary for optimal combustion. Any loose connection in the air intake system can result in air leaks, leading to inefficient air-fuel mixture and potentially causing the engine to run rough or stall.

Overall, the 3954196 Tube Clamp is a component in maintaining the reliability and efficiency of various engine systems by ensuring secure and leak-free connections.

Conclusion

The 3954196 Tube Clamp by Cummins is a vital component in the maintenance and operation of commercial truck engines. Its design and features contribute to the secure and efficient functioning of various engine systems, ensuring the reliability and performance of heavy-duty vehicles. Regular maintenance and proper installation are key to maximizing the benefits of this part.

-

Reif, K. (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2019). Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning.

↩ -

Hilgers, M. (2023). Electrical Systems and Mechatronics, Second Edition. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.