3954778

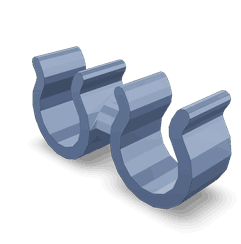

Tube Clamp

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3954778 Tube Clamp is a specialized component designed for use in commercial truck maintenance and operation. It serves a critical function within the truck’s tubing systems, ensuring secure connections and contributing to the overall efficiency and reliability of the vehicle.

Basic Concepts of Tube Clamps

Tube clamps are devices used to secure and connect tubing systems in both automotive and industrial applications. They function by compressing the tubing against a fixed surface, creating a tight seal that prevents leaks and ensures the integrity of the system. Tube clamps come in various designs and materials, tailored to meet the specific requirements of different applications 1.

Purpose of the 3954778 Tube Clamp in Truck Operation

The 3954778 Tube Clamp plays a role in the operation of commercial trucks by securing tubing connections in various systems and components. Its application ensures that fluids and gases are transported efficiently throughout the truck, contributing to the proper functioning of critical systems such as the fuel, brake, and hydraulic systems 2.

Key Features

The primary features of the 3954778 Tube Clamp include its material composition, which is designed to withstand the rigors of commercial truck operation, and its design elements that enhance its performance and durability. The clamp is engineered to provide a secure fit, reducing the risk of leaks and ensuring long-term reliability.

Benefits of Using the 3954778 Tube Clamp

The advantages provided by the 3954778 Tube Clamp include improved system integrity, ease of installation, and long-term reliability. Its design allows for quick and straightforward installation, minimizing downtime during maintenance procedures. Additionally, the clamp’s durable construction ensures that it can withstand the demands of commercial truck operation, providing a reliable solution for tubing connections 3.

Installation Process

The proper installation of the 3954778 Tube Clamp involves several steps to ensure a secure and effective connection. Best practices include cleaning the tubing and clamp surfaces before installation, ensuring that the clamp is properly aligned with the tubing, and tightening the clamp to the manufacturer’s specified torque. Avoiding common pitfalls such as over-tightening or improper alignment is crucial to the clamp’s performance and longevity.

Troubleshooting Common Issues

Frequent problems associated with tube clamps, such as leaks or improper fitting, can often be addressed through careful inspection and adjustment. Ensuring that the clamp is correctly installed and tightened to the appropriate torque can resolve many issues. In cases where leaks persist, inspecting the tubing and clamp for damage or wear may be necessary, with replacement parts installed as needed.

Maintenance Tips

Regular maintenance of the 3954778 Tube Clamp is important to ensure ongoing performance and longevity. This includes periodic inspection for signs of wear or damage, cleaning the clamp and tubing surfaces to remove any debris or contaminants, and tightening the clamp as necessary to maintain a secure connection. Adhering to recommended inspection intervals and maintenance procedures will help to prolong the life of the clamp and ensure the continued efficiency of the truck’s tubing systems.

Compatibility and Applications

The 3954778 Tube Clamp is designed for use within commercial truck systems, with applications in various components and systems. Its compatibility with other components or systems should be considered when selecting or replacing tube clamps to ensure optimal performance and reliability.

Cummins: A Brief Overview

Cummins Inc. is a well-established manufacturer in the commercial truck industry, known for its wide range of products and strong reputation for quality and reliability. The company’s history of innovation and commitment to excellence has made it a trusted name in the industry, with a product range that includes engines, filtration systems, and aftermarket parts designed to meet the needs of commercial truck operators 4.

Compatibility of Tube Clamp 3954778 with Cummins Engines

The Tube Clamp part number 3954778, manufactured by Cummins, is designed to fit a variety of Cummins engines. This clamp is essential for securing and maintaining the integrity of coolant and oil lines within the engine system. Below is a detailed breakdown of the engines that this tube clamp is compatible with, grouped by model series for clarity.

B Series Engines

- B5.6 CM2670 B152B

- B6.7 CM2670 B153B

The Tube Clamp 3954778 is suitable for securing coolant and oil lines in the B5.6 and B6.7 series engines, ensuring that these lines remain tightly fastened and leak-free.

F Series Engines

- F3.8 CM2620 F137B

- F4.5 CM2620 F139B

For the F3.8 and F4.5 engines, the Tube Clamp 3954778 is engineered to fit the specific configurations of these models, providing reliable clamping for the coolant and oil lines.

ISB Series Engines

- ISB CM2150

- ISB CM850

- ISB/ISD4.5 CM2150 B119

- ISB/ISD6.7 CM2150 SN

- ISB5.9 CM2880 B110

- ISB5.9 CM2880 B140

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

The Tube Clamp 3954778 is compatible with a wide range of ISB engines, including both the CM2150 and CM2880 models. This clamp is designed to fit the specific needs of these engines, ensuring that coolant and oil lines are securely fastened.

ISBE Series Engines

- ISBE CM2150

- ISBE CM800

- ISBE4 CM850

The Tube Clamp 3954778 is also suitable for the ISBE series engines, providing a reliable solution for securing coolant and oil lines in these models.

ISC Series Engines

- ISC CM2150

- ISC CM850

For the ISC series engines, the Tube Clamp 3954778 is designed to fit the specific configurations of these models, ensuring that coolant and oil lines are securely fastened.

ISD Series Engines

- ISD4.5 CM2220 D108

The Tube Clamp 3954778 is compatible with the ISD4.5 engine, providing a reliable solution for securing coolant and oil lines in this model.

ISL Series Engines

- ISL CM2150

- ISL9 CM2150 SN

The Tube Clamp 3954778 is suitable for the ISL series engines, ensuring that coolant and oil lines are securely fastened.

L Series Engines

- L9 CM2670 L128B

The Tube Clamp 3954778 is compatible with the L9 engine, providing a reliable solution for securing coolant and oil lines in this model.

QSB Series Engines

- QSB4.5 CM850(CM2850)

- QSB5.9 CM2880 B115

- QSB5.9 CM850

- QSB6.7 CM850(CM2850)

The Tube Clamp 3954778 is suitable for the QSB series engines, ensuring that coolant and oil lines are securely fastened in these models.

Role of Part 3954778 Tube Clamp in Engine Systems

The 3954778 Tube Clamp is instrumental in ensuring the secure and efficient operation of various engine systems. It plays a significant role in the arrangement of components by providing a reliable connection point for tubes and hoses, which is essential for maintaining system integrity and performance.

In the compressor coolant system, the Tube Clamp ensures that the coolant lines are firmly attached to the compressor, preventing leaks and ensuring consistent coolant flow. This is vital for the efficient operation of the compressor and the overall cooling system.

For the Electronic Control Module (ECM) wiring harness, the Tube Clamp secures the wiring harness to the chassis or other structural components. This not only protects the wiring from physical damage but also helps in managing the harness layout, reducing the risk of chafing or abrasion.

In the fuel system, the Tube Clamp is used in the fuel drain tube, fuel filter, and fuel filter plumbing. It ensures that fuel lines are securely connected, which is important for maintaining fuel pressure and preventing fuel leaks. The clamp’s role in the fuel plumbing and fuel supply tube is similarly significant, as it ensures a tight seal at connection points, which is essential for the safe and efficient delivery of fuel to the engine.

The Tube Clamp also finds its application in the gauge and oil level systems. By securing the oil level gauge tube, it ensures accurate oil level readings, which is important for engine maintenance and performance.

In the lubricating oil supply tube, the Tube Clamp ensures that the oil lines are securely connected, which is essential for maintaining proper lubrication of engine components. This helps in reducing wear and tear and extending the lifespan of the engine.

Furthermore, the Tube Clamp is used in the housing of various engine components, such as the flywheel, to secure tubes and hoses that supply or drain fluids. This ensures that the housing remains sealed and that the fluids are correctly routed.

Lastly, in the context of corrosion resistor applications, the Tube Clamp helps in securing tubes that may be exposed to corrosive environments, ensuring that the integrity of the tubes is maintained over time.

Overall, the 3954778 Tube Clamp is a versatile component that plays a key role in the secure and efficient operation of various engine systems.

Conclusion

The Cummins 3954778 Tube Clamp is a vital component in the maintenance and operation of commercial trucks. Its role in securing tubing connections across various systems ensures the efficient transport of fluids and gases, contributing to the overall reliability and performance of the vehicle. With its durable construction and ease of installation, this Cummins part offers long-term reliability and is compatible with a wide range of Cummins engines, making it an essential tool for truck maintenance professionals.

-

Mananathan, R. (2022). Automobile Wheel Alignment and Wheel Balancing. SAE International.

↩ -

Goodnight, N., & VanGelder, K. (2019). Automotive Braking Systems CDX Master Automotive Technician Series. Jones Bartlett Learning.

↩ -

Department of Energy. (2015). Department of Energy Fundamentals Handbook. Department of Energy.

↩ -

ElGindy, M., & ElSayegh, Z. (2023). Road and Off-Road Vehicle Dynamics. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.