This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

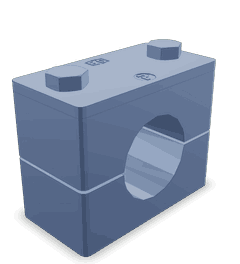

The Tube Clamp 4011095 by Cummins is a specialized component designed for use in commercial trucks. It serves to secure tubing systems, ensuring reliable connections that are vital for the proper operation of various truck systems. This clamp is part of Cummins’ extensive range of aftermarket parts, which are engineered to meet the demanding requirements of heavy-duty applications 1.

Basic Concepts of Tube Clamps

Tube clamps are mechanical fasteners used to secure tubing in automotive and industrial applications. They operate by compressing the tubing against a fixed surface, creating a secure and leak-proof connection. Tube clamps are preferred in situations where traditional welding or soldering is impractical, such as in systems where frequent disassembly and reassembly are required. They provide a versatile solution for securing tubing in a variety of orientations and under different operating conditions 2.

Purpose of Tube Clamp 4011095

The Tube Clamp 4011095 is specifically designed to play a role in the operation of commercial trucks by securing tubing in critical systems. Its applications include fuel lines, brake systems, and hydraulic lines, where secure and reliable connections are necessary to ensure the safe and efficient operation of the vehicle. By providing a robust clamping mechanism, this component helps maintain the integrity of these systems under various operating conditions.

Key Features

The Tube Clamp 4011095 features several design elements that enhance its functionality. It is constructed from high-strength materials, ensuring durability and resistance to corrosion. The clamp design includes a band that wraps around the tubing and a screw mechanism that tightens the band, creating a secure fit. Additionally, the clamp is designed to accommodate a range of tubing sizes, making it a versatile component for various applications.

Benefits of Using Tube Clamp 4011095

Using the Tube Clamp 4011095 offers several advantages. It provides a secure connection that resists vibration and movement, which is crucial in the dynamic environment of a commercial truck. The ease of installation allows for quick repairs and maintenance, reducing downtime. Furthermore, its durable construction ensures long-term reliability, even under harsh operating conditions.

Installation Process

Installing the Tube Clamp 4011095 involves several steps to ensure a secure fit. First, the tubing should be cleaned and inspected for any damage. The clamp band is then positioned around the tubing and the screw mechanism is tightened using the appropriate tools. It is important to achieve the correct tension to ensure a leak-proof connection without damaging the tubing. Following the manufacturer’s guidelines for torque specifications is recommended to achieve the best results.

Troubleshooting Common Issues

Common issues with tube clamps include leaks and loose connections. These problems can often be traced to improper installation or wear and tear over time. To address leaks, the clamp should be re-tightened or replaced if necessary. Loose connections may require re-positioning the clamp or using a larger size to achieve a better fit. Regular inspections can help identify and resolve these issues before they lead to more significant problems.

Maintenance Tips

Regular maintenance of the Tube Clamp 4011095 is important to ensure long-term performance. This includes periodic inspections for signs of wear, corrosion, or damage. Cleaning the clamp and tubing can prevent the buildup of debris that may affect the connection. Following the manufacturer’s recommendations for inspection intervals and maintenance procedures will help maintain the reliability of the tubing systems.

Cummins Corporation Overview

Cummins Corporation is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for innovation and quality in the commercial truck industry. The company offers a wide range of products and services, including aftermarket parts like the Tube Clamp 4011095, designed to meet the needs of heavy-duty applications.

Role of Part 4011095 Tube Clamp in Engine Systems

The 4011095 Tube Clamp is an essential component in securing and maintaining the integrity of various fluid pathways within engine systems. Its application is particularly significant in the context of the Filter, Oil Bypass, Oil Bypass Assembly Filter, and Oil Bypass Filter components.

Integration with Filter Systems

In filter systems, the 4011095 Tube Clamp ensures a secure connection between the filter housing and the associated tubing. This connection is vital for maintaining the efficiency of the filtration process. By providing a tight seal, the clamp prevents leaks and ensures that the fluid flow is directed correctly through the filter media, enhancing the overall performance and longevity of the filter.

Function in Oil Bypass Systems

When integrated with Oil Bypass systems, the 4011095 Tube Clamp plays a role in maintaining the structural stability of the bypass lines. These lines are designed to allow excess oil to bypass the filter when it becomes clogged, ensuring continuous lubrication of engine components. The clamp’s secure fit prevents any potential disconnections or leaks, which could lead to inadequate lubrication and subsequent engine damage.

Application in Oil Bypass Assembly Filter

In the Oil Bypass Assembly Filter, the 4011095 Tube Clamp is used to connect the bypass valve to the filter housing. This connection is important for the proper functioning of the assembly, as it allows for the regulated flow of oil through the bypass valve. The clamp ensures that the connection remains intact under varying pressure conditions, contributing to the reliable operation of the assembly.

Use in Oil Bypass Filter

For the Oil Bypass Filter, the 4011095 Tube Clamp is employed to secure the filter to its mounting bracket and the associated tubing. This secure attachment is important for the filter’s effectiveness in trapping contaminants while allowing clean oil to pass through. The clamp’s role in preventing leaks and maintaining a stable connection is important for the filter’s performance and the engine’s overall health.

Conclusion

In summary, the 4011095 Tube Clamp is a key component in ensuring the secure and efficient operation of various engine systems, particularly those involving fluid filtration and bypass mechanisms. Its proper installation and maintenance are important for the optimal performance and reliability of these systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.