This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

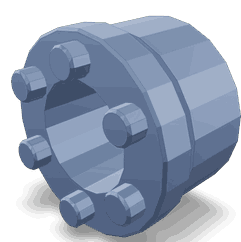

The Cummins 4012710 Clamping Ring is a critical component designed to secure various parts within the engine systems of commercial trucks. Its role is significant in maintaining the integrity and efficiency of truck operations. Cummins Inc., the manufacturer, is renowned in the industry for its commitment to quality and innovation in engine technology 1.

Basic Concepts of Clamping Rings

A clamping ring is a mechanical component used to hold parts in place by applying pressure. It operates by creating a secure fit between components, ensuring they remain aligned and functional under operational stress. Clamping rings are typically made from materials such as steel, stainless steel, or specialized alloys, chosen for their strength, durability, and resistance to wear and corrosion 2.

Purpose of the 4012710 Clamping Ring in Truck Operation

The 4012710 Clamping Ring plays a specific role in the operation of commercial trucks by securing components within the engine system. It interacts with various engine parts, ensuring they are held firmly in place, which contributes to the overall functionality and efficiency of the truck. This secure fit is vital for the proper operation of the engine, affecting performance and longevity 3.

Key Features of the 4012710 Clamping Ring

The 4012710 Clamping Ring is characterized by its robust design and material composition, which typically includes high-strength alloys. These features enhance its performance and durability, allowing it to withstand the demanding conditions of commercial truck operations. Its unique characteristics ensure a secure fit and reliable operation over time.

Benefits of Using the 4012710 Clamping Ring

Incorporating the 4012710 Clamping Ring into truck maintenance and repair offers several advantages. It contributes to improved performance and reliability of the truck’s components by ensuring a secure fit. This results in enhanced engine efficiency and longevity, reducing the need for frequent repairs and replacements.

Installation and Usage Guidelines

Proper installation of the 4012710 Clamping Ring involves following a series of steps to ensure a secure and effective fit. It is important to adhere to best practices, such as using the correct tools and ensuring the ring is properly aligned with the components it secures. Precautions should be taken to avoid damage to the ring or the components during installation.

Troubleshooting Common Issues

Common problems with the 4012710 Clamping Ring may include wear and tear, improper fit, or failure to secure components effectively. Addressing these issues involves inspecting the ring for signs of damage, ensuring it is correctly installed, and replacing it if necessary. Regular maintenance and careful installation can help prevent these problems.

Maintenance and Care

Regular maintenance and care of the 4012710 Clamping Ring are important for ensuring its longevity and optimal performance. This includes routine inspections for wear or damage, cleaning to remove any debris or contaminants, and considering replacement if the ring shows signs of significant wear or failure to function as intended.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of engine technologies and components. The company has a history of innovation and commitment to quality, which is reflected in its products, including the 4012710 Clamping Ring. Cummins’ dedication to customer satisfaction and continuous improvement underscores its standing in the industry.

Role of Part 4012710 Clamping Ring in Lubricating Oil Pump Systems

The part 4012710 Clamping Ring is an essential component in the assembly and operation of lubricating oil pump systems. It ensures the secure attachment of various components, maintaining the integrity and efficiency of the oil pump.

Integration with Lubricating Oil Pump

In lubricating oil pump systems, the Clamping Ring is utilized to hold the rotor and stator in place. This secure fit is necessary to prevent any misalignment that could lead to inefficient oil flow or damage to the pump components. The ring’s precise placement ensures that the rotor can spin freely within the stator, optimizing the pump’s performance.

Ensuring Seal Integrity

The Clamping Ring also plays a significant role in maintaining the seal between the pump housing and the rotor/stator assembly. By applying even pressure, it prevents oil leaks, which is vital for the consistent lubrication of engine components. This seal integrity is fundamental to the pump’s ability to deliver oil under pressure to various engine parts, ensuring they operate smoothly and with reduced wear.

Supporting Rotor Alignment

Proper alignment of the rotor is another area where the Clamping Ring contributes significantly. It helps in keeping the rotor centered within the pump housing, which is essential for the balanced distribution of oil flow. Misalignment can result in uneven wear and potential failure of the pump, making the role of the Clamping Ring indispensable in the longevity and reliability of the lubricating oil pump.

Facilitating Maintenance and Repairs

From a maintenance perspective, the Clamping Ring simplifies the process of disassembling and reassembling the pump. Its design allows for easy removal and replacement, which is beneficial during routine maintenance or when repairs are necessary. This feature not only saves time but also reduces the complexity of working on the pump, making it more accessible for engineers and mechanics.

Conclusion

The 4012710 Clamping Ring is a key component in the effective operation and maintenance of lubricating oil pump systems. Its role in securing components, ensuring seal integrity, supporting rotor alignment, and facilitating maintenance underscores its importance in the overall functionality of the pump. Regular maintenance and proper installation are crucial for maximizing the performance and longevity of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.