This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

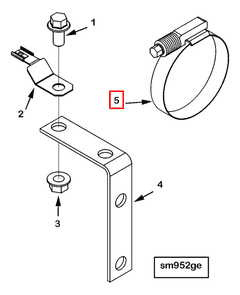

The Cummins 4095962 Wire Tie Clamp is a component designed to secure wires and cables in commercial trucks. Its role is significant in maintaining the integrity and organization of the electrical systems within these vehicles, ensuring that wires remain in place and protected from potential damage 2.

Basic Concepts of Wire Tie Clamps

Wire tie clamps are devices used to bundle and secure wires and cables. They function by wrapping around the wires and tightening to hold them in place. These clamps are widely used in automotive and industrial settings to manage wiring, reduce the risk of electrical faults, and protect wires from physical damage 1.

Purpose of the 4095962 Wire Tie Clamp

This part is specifically designed to secure wires and cables in commercial trucks. It plays a role in maintaining the organization of the electrical system by keeping wires bundled together and away from moving parts or sharp edges. This helps in reducing the risk of wire damage and ensures that the electrical connections remain secure and reliable 2.

Key Features

The 4095962 features a durable material composition, typically made from high-strength polymers or metals, ensuring it can withstand the rigors of commercial truck environments. Its design includes a tightening mechanism that allows for secure clamping without the need for additional tools. Additionally, it may have unique characteristics such as weather resistance and flexibility to accommodate various wire sizes and configurations 2.

Benefits of Using the 4095962 Wire Tie Clamp

Using this Cummins part offers several advantages. It improves wire management by keeping cables organized and reducing the likelihood of tangling or fraying. This enhances safety by minimizing the risk of electrical shorts or fires caused by exposed wires. Furthermore, its durable construction ensures longevity, even in harsh operating conditions, contributing to the overall reliability of the truck’s electrical system 2.

Installation Process

To install the 4095962, first, identify the wires or cables that need securing. Place the clamp around the bundle, ensuring it is positioned correctly. Use the tightening mechanism to secure the clamp firmly in place. It is important to ensure that the wires are not twisted or damaged during the process. Tools required may include a screwdriver or pliers, depending on the specific design of the clamp 2.

Troubleshooting Common Issues

Common issues with wire tie clamps may include loosening over time or damage from environmental factors. To address these, regularly inspect the clamps for signs of wear or loosening. If a clamp is found to be loose, re-tighten it as necessary. In cases of damage, replace the clamp to maintain the integrity of the wiring system 2.

Maintenance Tips

Regular maintenance of the 4095962 involves periodic inspection to ensure it remains secure and in good condition. Check for any signs of wear, corrosion, or damage. If the clamp shows signs of deterioration, it should be replaced to prevent potential electrical issues. Additionally, ensure that the wires remain properly bundled and that there is no excessive tension on the clamp, which could lead to failure 2.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions systems. With a strong reputation in the commercial truck industry, Cummins is known for its high-quality products and commitment to innovation and customer satisfaction. The company’s extensive product range and focus on reliability make it a preferred choice for commercial vehicle operators and manufacturers 3.

Wire Tie Clamp 4095962 Compatibility with Cummins Engines

The Wire Tie Clamp 4095962, manufactured by Cummins, is a versatile component designed to secure and organize wiring harnesses and other components within the engine compartment. This part is compatible with several Cummins engine models, ensuring a secure fit and reliable performance across different engine configurations 3.

QSK19 CM2350 K144G and QSK50 CM2150 MCRS

The Wire Tie Clamp 4095962 is specifically engineered to fit the QSK19 CM2350 K144G and QSK50 CM2150 MCRS engines. These engines, known for their robust design and high performance, benefit from the clamp’s ability to maintain organized wiring and reduce the risk of cable damage. The clamp’s design allows for easy installation and adjustment, ensuring that it can be securely fastened in various engine compartments without compromising the integrity of the wiring 3.

QSK60 CM850 MCRS

Similarly, the QSK60 CM850 MCRS engine is another model that can effectively utilize the Wire Tie Clamp 4095962. This engine, like its counterparts, requires precise wiring management to ensure optimal performance and longevity. The clamp’s compatibility with the QSK60 CM850 MCRS ensures that the wiring remains neatly arranged, reducing the likelihood of interference and enhancing the overall efficiency of the engine system 3.

By integrating the Wire Tie Clamp 4095962 into these Cummins engines, users can expect improved cable management, reduced wear and tear on wiring, and a more streamlined engine compartment. This compatibility highlights Cummins’ commitment to providing high-quality, reliable components that enhance the functionality and performance of their engines 3.

Role of Part 4095962 Wire Tie Clamp in Engine Systems

The 4095962 is an essential component in the organization and maintenance of wiring systems within various engine setups. It is specifically designed to secure and manage the Electronic Control Module (ECM) Wiring Harness, ensuring that the wires remain neatly bundled and protected from potential damage 2.

When installed, the Wire Tie Clamp effectively holds the ECM Wiring Harness in place, preventing it from coming into contact with moving parts or sharp edges within the engine compartment. This is particularly important around the Starting Motor, where vibrations and movement are common. By securing the harness, the clamp helps maintain the integrity of the electrical connections, which is vital for the reliable operation of the ECM 2.

Additionally, the clamp plays a significant role in the overall Mounting of the wiring harness. It ensures that the harness is positioned correctly and does not interfere with other components or obstruct access to critical areas of the engine. This is important for both the installation process and for any future maintenance or repairs that may be required 2.

Conclusion

In summary, the 4095962 Wire Tie Clamp is a key element in the proper installation and maintenance of the ECM Wiring Harness, contributing to the efficient and safe operation of the engine system. Its compatibility with various Cummins engine models underscores its versatility and importance in ensuring reliable and organized wiring systems 23.

-

Ribbens, W. B. (2003). Understanding Automotive Electronics. Elsevier Science.

↩ -

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ -

Miedema, S. A., & Lu, Z. (2010). The Dynamic Behavior of a Diesel Engine. Published by Drir S. A. Miedema.

↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.