This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4096766 Tube Clamp is a component designed to secure tubing systems in commercial trucks. Its role is significant in maintaining the integrity and efficiency of various truck systems by ensuring that tubing connections remain secure under operational conditions.

Basic Concepts of Tube Clamps

Tube clamps are devices used to hold tubing in place, commonly found in automotive and industrial applications. They function by compressing the tubing against a fixed surface, creating a secure connection that can withstand vibrations and pressure fluctuations. This mechanism is vital for the reliable operation of fluid and gas transport systems within vehicles 1.

Purpose of the Cummins 4096766 Tube Clamp

The Cummins 4096766 Tube Clamp is specifically designed to secure tubing in truck systems. It plays a role in various applications, including fuel lines, hydraulic systems, and coolant passages. By providing a stable connection, it helps maintain the efficiency and safety of these systems 2.

Key Features

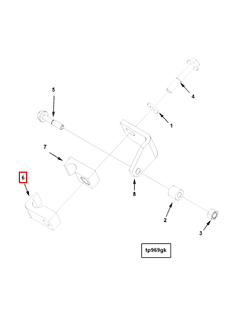

The Cummins 4096766 Tube Clamp is constructed from durable materials, ensuring longevity and resistance to corrosion. Its design includes features such as a band that wraps around the tubing and a screw mechanism to tighten the clamp, allowing for adjustable tension. These attributes contribute to its effectiveness in securing tubing systems 3.

Benefits of Using the Cummins 4096766 Tube Clamp

Utilizing the Cummins 4096766 Tube Clamp offers several advantages. Its robust construction ensures durability, while the adjustable design facilitates ease of installation. Additionally, its reliable performance in securing tubing systems contributes to the overall efficiency and safety of truck operations.

Installation Process

Installing the Cummins 4096766 Tube Clamp involves positioning the clamp around the tubing, ensuring it is aligned correctly. Using the provided screw mechanism, the clamp is then tightened to secure the tubing in place. It is important to use the appropriate tools and follow best practices to achieve a secure fit without over-tightening, which could damage the tubing.

Maintenance and Troubleshooting

To maintain the Cummins 4096766 Tube Clamp, regular inspections for signs of wear or corrosion are recommended. Common issues may include loosening of the clamp or damage to the tubing. Troubleshooting tips include re-tightening the clamp if necessary and replacing it if significant wear is observed to ensure continued secure connections.

Compatibility and Applications

The Cummins 4096766 Tube Clamp is designed for use in various truck systems, including but not limited to fuel, hydraulic, and coolant systems. Its compatibility with these systems ensures that it can be effectively utilized across a range of applications within the commercial truck industry.

Safety Considerations

When installing or maintaining the Cummins 4096766 Tube Clamp, it is important to adhere to safety practices. This includes wearing appropriate personal protective equipment, ensuring the truck is properly secured and powered down during installation, and following manufacturer guidelines to prevent accidents and ensure the clamp operates correctly.

Cummins Corporation

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of products including engines, filtration systems, and aftermarket parts. The company has a reputation for quality and reliability, backed by a history of innovation and commitment to customer satisfaction.

Compatibility with Cummins Engines

The Tube Clamp 4096766, manufactured by Cummins, is designed to secure and stabilize various tubes and hoses within the engine compartment. This part is integral to maintaining the integrity of the engine’s cooling and fuel systems, ensuring that all connections remain tight and leak-free.

Compatibility with QSK23 Series Engines

The Tube Clamp 4096766 is specifically engineered to fit the QSK23 series engines, which include the following models:

- QSK23 CM2250 K109

- QSK23 CM2350 K127

- QSK23 CM500

These engines are known for their robust performance and reliability, often used in heavy-duty applications such as marine and industrial settings. The Tube Clamp 4096766 ensures that the tubes and hoses within these engines are securely fastened, preventing any potential leaks that could compromise engine performance.

Installation and Usage

When installing the Tube Clamp 4096766 on QSK23 series engines, it is essential to follow proper procedures to ensure a secure fit. The clamp should be positioned around the tube or hose, and then tightened to the manufacturer’s specified torque settings. This will maintain the clamp’s effectiveness over the engine’s operational life.

Importance of Proper Fitment

Using the correct Tube Clamp for your QSK23 series engine is vital for maintaining engine efficiency and longevity. An improperly fitted clamp can lead to leaks, which can cause overheating, fuel inefficiencies, and other performance issues. Therefore, it is recommended to use only genuine Cummins parts for any engine maintenance or repair work.

Role of Part 4096766 Tube Clamp in Engine Systems

The 4096766 Tube Clamp is a component in various engine systems, ensuring the secure and efficient connection of tubes and hoses. Its application spans across multiple subsystems, each requiring reliable and robust clamping solutions.

Compressor Systems

In compressor systems, the 4096766 Tube Clamp is utilized to connect the high-pressure air lines that deliver compressed air to different parts of the engine. This ensures that the air supply remains consistent and unimpeded, which is vital for the compressor’s performance and the overall efficiency of the engine.

Air Systems

For air systems, particularly those involving intercoolers or air intake modifications, the Tube Clamp plays a significant role. It secures the air tubes that route cool air into the engine, maintaining the integrity of the air pathway and preventing leaks that could compromise engine performance.

Plumbing Systems

In general plumbing applications within engine systems, the 4096766 Tube Clamp is employed to join various fluid lines, including coolant and oil lines. This ensures that these critical fluids are delivered efficiently to their respective components, contributing to the engine’s thermal management and lubrication systems.

Turbocharger Systems

Within turbocharger systems, the Tube Clamp is instrumental in securing the turbocharger plumbing. It connects the intake and exhaust sides of the turbocharger, ensuring that the airflow is managed effectively. This is particularly important in maintaining the turbocharger’s efficiency and the engine’s overall power output.

Turbocharger Kit Installations

When installing a turbocharger kit, the 4096766 Tube Clamp is used extensively. It ensures that all new plumbing, including the intercooler pipes and boost lines, are securely fastened. This is essential for handling the increased air pressure and flow that a turbocharger introduces, ensuring that the system operates smoothly and reliably.

Turbocharger Plumbing

Specifically, in turbocharger plumbing, the Tube Clamp is crucial for connecting the various components such as the wastegate, blow-off valve, and charge pipes. It ensures that these connections are tight and leak-free, which is essential for maintaining the turbocharger’s performance and the engine’s overall efficiency.

Conclusion

The Cummins 4096766 Tube Clamp is a vital component in the maintenance and operation of commercial truck systems. Its durable construction, adjustable design, and compatibility with various engine systems make it an essential part for ensuring the secure and efficient connection of tubes and hoses. Proper installation, maintenance, and the use of genuine Cummins parts are recommended to ensure the longevity and performance of the engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.