This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4096770 Wire Tie Clamp is a component designed to secure wires and cables in commercial trucks. Its role is significant in maintaining the integrity and organization of the electrical systems within these vehicles, ensuring that wires remain in place and protected from potential damage.

Basic Concepts of Wire Tie Clamps

Wire tie clamps are devices used to bundle and secure wires and cables. They function by compressing around the wires, holding them together and preventing movement. These clamps are widely used in automotive and industrial settings to manage wiring, reduce clutter, and protect cables from wear and tear 1.

Purpose of the 4096770 Wire Tie Clamp

This Cummins part is specifically designed for use in commercial trucks. It plays a role in securing wires and cables, which helps in maintaining the electrical system’s organization and integrity. By keeping wires in place, it reduces the risk of electrical issues caused by loose or damaged cables.

Key Features

This part is constructed from durable materials, ensuring it can withstand the rigors of commercial truck environments. Its design includes features that allow for easy installation and adjustment, enabling mechanics to secure wires efficiently. Additionally, the clamp is designed to provide a secure hold without damaging the wires it encases.

Benefits

Using this Cummins part offers several benefits. It improves wire management by keeping cables organized and secured, which can lead to easier troubleshooting and maintenance. Enhanced safety is another benefit, as secured wires are less likely to cause electrical shorts or other hazards. The clamp’s durability ensures long-term use without the need for frequent replacements.

Installation Process

Installing the 4096770 involves positioning it around the wires to be secured, then tightening it to the desired level. Tools required may include a screwdriver for adjustment. Best practices include ensuring the clamp is not over-tightened to avoid damaging the wires and checking that all wires are securely held without excess slack.

Troubleshooting and Maintenance

Common issues with wire tie clamps may include loosening over time or damage from environmental factors. Troubleshooting steps involve checking the clamp’s tightness and condition, replacing it if necessary. Maintenance tips include regular inspections to ensure the clamp remains secure and functional, and replacing it if signs of wear or damage are observed.

Compatibility and Applications

The 4096770 is designed for use in various commercial truck models. Its applications within the industry are notable for improving the organization and protection of electrical systems in these vehicles.

Safety Considerations

When installing and maintaining this Cummins part, it is important to observe safety guidelines. This includes ensuring the electrical system is powered down during installation to prevent electrical shocks. Mechanics should also wear appropriate personal protective equipment to safeguard against any potential hazards.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its commitment to quality and innovation. With a history of providing reliable and efficient components, Cummins continues to be a trusted name in the field, offering solutions that enhance the performance and safety of commercial vehicles.

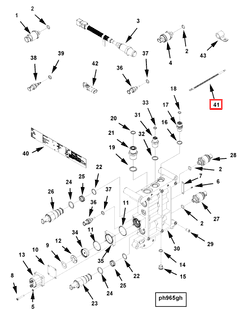

Wire Tie Clamp 4096770 in Cummins Engines

The Wire Tie Clamp 4096770, manufactured by Cummins, is a critical component in the assembly and maintenance of various Cummins engines. This part is designed to secure wires and cables, ensuring they remain in place and do not interfere with engine operations. Its application is widespread across several engine models, including the QSB4.5 CM2250 EC.

In the QSB4.5 CM2250 EC engine, the Wire Tie Clamp 4096770 is used to manage the routing and securing of electrical wires. This is essential for maintaining a clean and organized engine compartment, which is crucial for both the efficiency of the engine and the ease of maintenance. The clamp’s robust design ensures that it can withstand the harsh conditions within the engine bay, including vibrations and temperature fluctuations.

The Wire Tie Clamp 4096770 is also utilized in other Cummins engines, where it serves the same purpose of securing and organizing wiring. Its versatility and reliability make it a staple in the maintenance and repair of Cummins engines, ensuring that electrical connections remain stable and secure throughout the engine’s operational life.

Role of Part 4096770 Wire Tie Clamp in Engine Systems

This part is an essential component in the assembly and maintenance of various engine systems. It is primarily used to secure and organize wiring harnesses and electronic control module (ECM) wiring, ensuring that these critical components remain in place and are protected from potential damage.

In the context of the Engine Control Module (ECM), the Wire Tie Clamp plays a significant role. It is employed during the Engine Control Module Mounting process to keep the wiring harnesses neatly arranged. This organization is vital for the proper functioning of the ECM, as it ensures that all connections are secure and that there is no risk of wires becoming dislodged or damaged during engine operation.

Furthermore, the Wire Tie Clamp is integral in the documentation and declaration incorporation phases of engine system assembly. It helps in maintaining the integrity of the wiring harnesses, which are often subject to vibration and movement within the engine compartment. By securing these wires, the clamp contributes to the overall reliability and performance of the engine control system.

Conclusion

In summary, the 4096770 Wire Tie Clamp is a fundamental component in the assembly and maintenance of engine systems. Its role in securing and organizing wiring harnesses and ECM wiring is essential for the proper operation and longevity of the engine control module and associated components.

-

Harrison, Matthew. Controlling Noise and Vibration in Road Vehicles. SAE International, 2004.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.