This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

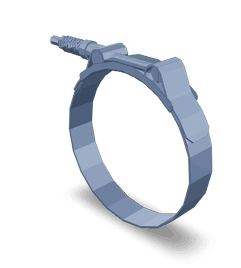

The T Bolt Clamp 4101293, manufactured by Cummins, is a specialized component designed for use in commercial truck operations. Cummins is known for its commitment to quality and innovation in the automotive industry. This part is significant in truck maintenance and repair, offering a reliable solution for securing various components within the truck’s structure.

Basic Concepts and Functionality

A T Bolt Clamp is a type of fastener that operates by clamping two surfaces together using a T-shaped bolt. This design allows for a secure and stable connection, which is important in environments where vibrations and dynamic loads are common. In truck maintenance and repair, T Bolt Clamps are often used to secure components such as pipes, hoses, and other structural elements, ensuring they remain firmly in place under operational conditions 1.

Purpose and Role in Truck Operation

This Cummins part plays a specific role in the operation of commercial trucks by securing components and contributing to the structural integrity of the vehicle. It is designed to withstand the rigors of heavy-duty use, providing a stable connection that helps prevent component failure and ensures the safe and efficient operation of the truck. By securing critical components, the T Bolt Clamp helps maintain the alignment and functionality of various systems within the truck 2.

Key Features

The T Bolt Clamp 4101293 is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials, ensuring resistance to corrosion and wear. The design includes a T-shaped bolt that provides a strong clamping force, and the clamp itself is engineered to distribute pressure evenly across the surfaces it secures. These features contribute to the clamp’s reliability and longevity in demanding applications 3.

Benefits

Utilizing the T Bolt Clamp 4101293 offers several advantages in truck maintenance procedures. Its robust design and secure clamping mechanism improve safety by reducing the risk of component detachment during operation. The reliability of the clamp enhances the overall efficiency of maintenance tasks, allowing for quicker and more secure installations. Additionally, the durability of the T Bolt Clamp contributes to reduced maintenance frequency, offering long-term cost savings.

Installation Process

Installing the T Bolt Clamp 4101293 requires careful attention to detail to ensure a secure and effective connection. The process involves positioning the clamp over the components to be secured, aligning the T-shaped bolt with the designated holes, and tightening the bolt to achieve the desired clamping force. It is important to follow manufacturer guidelines for torque specifications to avoid over-tightening, which can damage the components, or under-tightening, which can compromise the security of the connection.

Troubleshooting and Maintenance

Common issues with T Bolt Clamps may include corrosion, wear, or loosening over time. Regular inspection and maintenance are recommended to identify and address these issues promptly. Maintenance practices should include cleaning the clamp and its mating surfaces, checking for signs of wear or damage, and ensuring the clamping force remains adequate. In cases where corrosion is present, applying a corrosion-resistant coating can help extend the life of the clamp.

Compatibility and Applications

The T Bolt Clamp 4101293 is designed for use in a variety of commercial truck applications, where it is commonly employed to secure pipes, hoses, and other components. Its compatibility with different truck models and systems makes it a versatile choice for maintenance and repair tasks. When selecting a T Bolt Clamp for a specific application, it is important to consider the size, material, and clamping force requirements to ensure optimal performance.

Cummins Overview

Cummins is a renowned manufacturer in the automotive industry, with a history of innovation and quality in the production of automotive components. The company’s reputation is built on a commitment to developing reliable and efficient solutions for the transportation sector. Cummins’ products, including the T Bolt Clamp 4101293, are designed with the aim of enhancing the performance, safety, and durability of commercial vehicles.

Cummins Engine Compatibility with Part 4101293

This part is designed to fit into several of Cummins’ engine models. It is integral in securing various components within the engine, ensuring stability and safety during operation.

QSK45 CM500 and QSK60 CM500

Both the QSK45 CM500 and QSK60 CM500 engines utilize the t Bolt Clamp part 4101293. This part is essential in maintaining the structural integrity of the engine by securing certain components in place. Its application in these engines ensures that the engine operates smoothly and efficiently.

QSK60 CM850 MCRS and QSK60G

The QSK60 CM850 MCRS and QSK60G engines also incorporate the t Bolt Clamp part 4101293. In these engines, the part plays a crucial role in securing components that are subject to high stress and vibration. This ensures that the engine maintains its operational integrity under demanding conditions.

By using the t Bolt Clamp part 4101293, Cummins ensures that these engines can perform reliably and efficiently, maintaining the high standards for which Cummins is known.

Role of Part 4101293 T Bolt Clamp in Engine Systems

The 4101293 T Bolt Clamp is an essential component in securing and maintaining the integrity of various engine system connections. Its application is particularly significant in the following areas:

Air Cleaner System

In the air cleaner system, the T Bolt Clamp ensures a secure connection between the air intake hose and the throttle body or carburetor. This connection is vital for maintaining an airtight seal, which is necessary for optimal airflow into the engine. Proper airflow is essential for efficient combustion and overall engine performance.

Air Tube Connections

The T Bolt Clamp is utilized to connect various air tubes within the engine system. These tubes may include those leading to secondary air injection systems, turbo chargers, or intercoolers. By providing a reliable clamp, it ensures that there are no leaks in the air passages, which could otherwise lead to a decrease in engine efficiency and performance.

Brace and Support Structures

In some engine configurations, the T Bolt Clamp is used to secure brace components that support air tubes and other engine parts. These braces help in maintaining the structural integrity of the engine bay, ensuring that components remain in their designated positions under various driving conditions. This is particularly important in high-performance engines where vibrations and stresses are more pronounced.

The T Bolt Clamp’s role in these systems underscores its importance in maintaining both the functional and structural aspects of engine components.

Conclusion

The T Bolt Clamp 4101293 is a critical component in the maintenance and operation of commercial trucks and engines. Its design and functionality contribute to the safety, efficiency, and durability of these vehicles. By securing various components and ensuring stable connections, this Cummins part plays a vital role in the overall performance of commercial trucks and engines.

-

Gillespie, Thomas D. Fundamentals of Vehicle Dynamics. SAE International, 2021.

↩ -

Hilgers, Michael and Achenbach, Wilfried. Vocational Vehicles and Applications. Springer Vieweg, 2021.

↩ -

Zhan, Quansheng, Eben, Shengbo, and Deng, Li Kun. Automotive Heating Ventilation and Air Conditioning. Jones Bartlett Learning, 2018.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.