This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

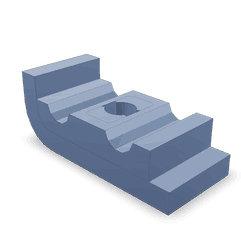

The 4303101 Tube Clamp is a component manufactured by Cummins, a well-established name in the commercial truck industry. This tube clamp is designed for use in commercial trucks, where it plays a role in securing and maintaining the integrity of various tubing systems. Tube clamps are integral to ensuring the safe and efficient operation of truck systems by providing a secure connection between tubes and other components.

Basic Concepts of Tube Clamps

Tube clamps are mechanical devices used to hold tubes in place, ensuring a secure and leak-proof connection. They function by applying pressure around the tube, creating a tight seal that prevents fluid or gas leakage. In automotive and industrial applications, tube clamps are commonly used in fuel, coolant, and hydraulic systems. Materials for tube clamps typically include stainless steel, aluminum, and various polymers, each offering different levels of durability, corrosion resistance, and flexibility 1.

Purpose of the 4303101 Tube Clamp in Truck Operations

The 4303101 Tube Clamp is specifically designed to play a role in the operation of commercial trucks by securing tubing in critical systems. It is often associated with fuel lines, coolant systems, and hydraulic lines, where maintaining a secure and leak-free connection is vital for the truck’s performance and safety. By ensuring these connections remain intact, the tube clamp contributes to the overall reliability and efficiency of the truck’s systems 2.

Key Features of the 4303101 Tube Clamp

The 4303101 Tube Clamp features a design that includes a band, typically made from durable materials like stainless steel, and a screw mechanism for tightening. This design allows for adjustable clamping force, ensuring a secure fit on various tube sizes. The construction materials are chosen for their strength and resistance to corrosion, enhancing the clamp’s functionality and durability in the demanding environment of commercial truck operations 3.

Benefits of Using the 4303101 Tube Clamp

Incorporating the 4303101 Tube Clamp into truck maintenance and repair offers several advantages. Its design allows for easy installation, reducing downtime during maintenance procedures. The clamp’s durability and resistance to corrosion contribute to improved reliability, ensuring long-term performance. Additionally, the use of high-quality tube clamps can lead to long-term cost savings by reducing the need for frequent replacements and repairs.

Installation and Usage Guidelines

Proper installation of the 4303101 Tube Clamp involves several steps to ensure a secure and effective connection. Begin by cleaning the tube and clamp surfaces to remove any debris or contaminants. Position the clamp around the tube and use the provided screw mechanism to tighten it, ensuring even pressure around the tube. Tools required may include a wrench for tightening. Safety precautions include wearing protective gloves and ensuring the truck is turned off and cooled down before beginning work.

Troubleshooting Common Issues with Tube Clamps

Common problems with tube clamps, such as leaks or loosening, can often be traced back to improper installation or wear and tear. To diagnose these issues, inspect the clamp for signs of corrosion, damage, or improper tightening. Resolving these issues may involve re-tightening the clamp, replacing worn components, or addressing underlying problems with the tubing system.

Maintenance Tips for Tube Clamps

Regular maintenance checks for tube clamps involve inspecting for signs of wear, corrosion, or damage. Cleaning the clamp and surrounding areas can prevent buildup that may affect performance. Replacement should be considered when signs of significant wear or damage are present, or if leaks occur despite tightening efforts. Adhering to manufacturer guidelines for maintenance can ensure ongoing performance and longevity of the tube clamps.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s commitment to manufacturing high-quality components, including the 4303101 Tube Clamp, underscores its dedication to enhancing the performance and reliability of commercial trucks.

Role of Part 4303101 Tube Clamp in Engine Systems

The 4303101 Tube Clamp is an essential component in ensuring the secure and efficient operation of various engine systems. It plays a significant role in the integration and functionality of the fuel manifold, injectors, and overall fuel supply system.

Fuel Manifold Integration

In engine systems, the fuel manifold is responsible for distributing fuel to multiple injectors. The 4303101 Tube Clamp ensures that the connections between the fuel manifold and the fuel lines are tight and leak-free. This secure fitting is vital for maintaining consistent fuel pressure and flow, which directly impacts engine performance 4.

Injector Functionality

Injectors rely on precise fuel delivery to operate effectively. The Tube Clamp secures the fuel lines to the injectors, preventing any potential leaks or disconnections that could disrupt fuel supply. This ensures that each injector receives a consistent and accurate amount of fuel, contributing to optimal combustion and engine efficiency.

Plumbing and Fuel Supply System

The overall plumbing of the fuel supply system benefits significantly from the use of the 4303101 Tube Clamp. It provides a reliable method for connecting various parts of the fuel lines, ensuring that the fuel supply remains uninterrupted. This is particularly important in high-performance engines where any disruption in fuel delivery can lead to decreased performance and potential engine damage.

Performance and Reliability

By ensuring secure connections throughout the fuel system, the 4303101 Tube Clamp contributes to the overall performance and reliability of the engine. It helps maintain the integrity of the fuel lines under various operating conditions, from idle to full throttle, ensuring that the engine operates smoothly and efficiently.

Conclusion

The 4303101 Tube Clamp plays a crucial role in the maintenance and operation of commercial truck systems. Its design and functionality contribute to the secure and efficient operation of fuel, coolant, and hydraulic systems. By ensuring secure connections and preventing leaks, this Cummins part enhances the reliability and performance of commercial trucks, making it a valuable component in truck maintenance and repair.

-

Robert Bosch GmbH, Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition, Springer Vieweg, 2007.

↩ -

Karsten Berns, Klaus Dressler, Patrick Fleischmann, Daniel Grges, Ralf Kalmar, Bernd Sauer, Nicole Stephan, Roman Teutsch, Martin Thul, Proceedings of the 5th Commercial Vehicle Technology Symposium CVT, Springer, 2018.

↩ -

Zhiyu Han, Simulation and Optimization of Internal Combustion Engines, SAE International, 2022.

↩ -

Cummins Inc., Operation and Maintenance Manual, Bulletin Number 5504153, ISX12N CM2380 X120B.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.