This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

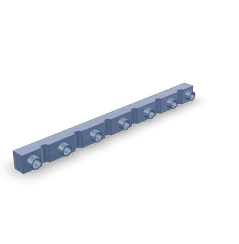

The Cummins 4303109 Tube Clamp is a component designed for use in commercial truck maintenance and operation. It serves a specific function within the truck’s systems, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and significance is key to maintaining and operating commercial trucks effectively.

Basic Concepts of Tube Clamps

Tube clamps are devices used to secure and connect tubing systems in various automotive and industrial applications. They function by compressing the tubing between two surfaces, creating a tight seal that prevents leaks and ensures the integrity of the system. Tube clamps are valued for their ease of installation, adjustability, and the secure connections they provide 1.

Purpose of the 4303109 Tube Clamp in Truck Operation

This Cummins part plays a role in the operation of commercial trucks by securing tubing connections in various systems and components. Its application ensures that fluids and gases are transported efficiently and without leakage, contributing to the truck’s performance and safety. This clamp is particularly important in systems where vibrations and movements are common, as it provides a reliable connection that can withstand these conditions.

Key Features

The 4303109 is characterized by several key features that enhance its functionality and durability. It is made from materials that offer resistance to corrosion and wear, ensuring long-term performance. Its design includes adjustable bands that allow for a secure fit on a range of tubing sizes, and it features a locking mechanism that prevents loosening over time. These attributes make it a reliable choice for commercial truck applications.

Benefits of Using the 4303109 Tube Clamp

Using this part offers several advantages. It provides improved reliability in tubing connections, reducing the risk of leaks and system failures. The clamp’s design allows for easy installation, minimizing downtime during maintenance procedures. Additionally, its durability and resistance to environmental factors contribute to lower maintenance costs and extended service life compared to alternative fastening methods 2.

Installation Process

Installing the 4303109 requires following a series of steps to ensure a secure and effective connection. First, the tubing should be cleaned and prepared for clamping. The clamp is then positioned around the tubing, and the bands are tightened using the appropriate tools until a snug fit is achieved. It is important to follow the manufacturer’s guidelines for torque settings to avoid over-tightening, which can damage the tubing.

Troubleshooting Common Issues

Common issues with tube clamps, such as leaks or improper fitting, can often be traced back to incorrect installation or wear and tear. To address these problems, it is important to inspect the clamp and tubing for signs of damage or misalignment. Re-tightening the clamp or replacing damaged components can resolve many issues, ensuring the system remains secure and leak-free.

Maintenance Tips

Regular maintenance of the 4303109 is important for ensuring long-term performance and reliability. This includes periodic inspections for signs of wear, corrosion, or loosening. Cleaning the clamp and tubing, and lubricating moving parts as necessary, can help prevent issues and extend the service life of the component. Following the manufacturer’s maintenance schedule will contribute to the overall efficiency of the truck’s systems.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a strong reputation in the commercial truck and engine industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and global presence make it a trusted partner for commercial vehicle operators and manufacturers.

Tube Clamp 4303109 Compatibility with Cummins Engines

The Tube Clamp part number 4303109, manufactured by Cummins, is designed to fit seamlessly with a range of Cummins engines. This clamp is crucial for maintaining the integrity of the engine’s cooling and exhaust systems by securing tubes and hoses in place.

QST30 Engine

In the QST30 engine, the Tube Clamp 4303109 is used to secure various coolant and exhaust tubes. Its robust design ensures that these components remain firmly attached, preventing leaks and maintaining optimal engine performance.

CM2350 and T101 Engines

For the CM2350 and T101 engines, the Tube Clamp 4303109 plays a vital role in securing high-pressure coolant and exhaust tubes. These engines, known for their reliability and efficiency, benefit from the clamp’s precision fit, which helps in maintaining the structural integrity of the engine’s systems.

Grouped Application

The Tube Clamp 4303109 is particularly effective in engines where high-temperature and high-pressure conditions are prevalent. Its application across the QST30, CM2350, and T101 engines highlights its versatility and importance in ensuring the longevity and efficiency of these engines.

Role of Part 4303109 Tube Clamp in Engine Systems

The 4303109 Tube Clamp is an essential component in ensuring the secure and efficient operation of various engine systems. Its primary function is to maintain a tight and reliable connection between tubing and fittings, which is vital for the overall performance and safety of the engine.

Integration with Fuel Manifold

In the context of a fuel manifold, the 4303109 Tube Clamp plays a significant role. It ensures that the connections between the manifold and the fuel lines are secure, preventing any potential leaks that could compromise fuel delivery. This is particularly important in high-performance engines where precise fuel distribution is necessary for optimal operation.

Connection to Injectors

When interfacing with fuel injectors, the 4303109 Tube Clamp ensures that the fuel lines are firmly attached. This is important for maintaining consistent fuel pressure and flow, which directly impacts the injector’s performance. A secure connection helps in delivering the correct amount of fuel at the right time, enhancing engine efficiency and reducing the risk of misfires.

Role in Plumbing Systems

In the broader scope of engine plumbing, the 4303109 Tube Clamp is used to connect various parts of the fuel supply system. Whether it’s linking the fuel tank to the fuel pump or connecting the fuel lines to the engine components, the clamp ensures that all connections are leak-free and robust. This is essential for maintaining the integrity of the fuel supply system under varying engine loads and conditions.

Enhancing Overall Performance

By ensuring secure and reliable connections throughout the fuel system, the 4303109 Tube Clamp contributes to the overall performance of the engine. It helps in maintaining consistent fuel pressure, reducing the likelihood of fuel starvation, and ensuring that the engine operates smoothly under all conditions. This is particularly beneficial in high-performance applications where even minor inconsistencies can have a significant impact on engine output and reliability 3.

Conclusion

The Cummins 4303109 Tube Clamp is a critical component in the maintenance and operation of commercial trucks and engines. Its design and features ensure secure and reliable connections in various systems, contributing to the overall efficiency, safety, and performance of the vehicle. Regular maintenance and proper installation are key to maximizing the benefits of this part, ensuring long-term reliability and performance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.