This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

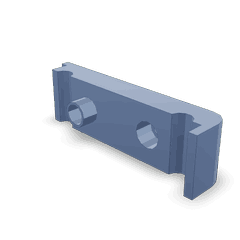

The Cummins 4303123 Tube Clamp is a component designed for use in commercial truck maintenance and operation. Its role is to secure and connect tubing systems, ensuring the integrity and efficiency of various truck systems. Understanding its function and significance is vital for maintaining the performance and reliability of commercial vehicles.

Basic Concepts of Tube Clamps

Tube clamps are devices used to secure and connect tubing in automotive and industrial applications. They function by compressing the tubing between two surfaces, creating a tight seal that prevents leaks and ensures the smooth flow of fluids or gases. Tube clamps are particularly useful in systems where tubing must be connected without welding, allowing for easier installation, removal, and maintenance 1.

Purpose of the Cummins 4303123 Tube Clamp

The Cummins 4303123 Tube Clamp is specifically designed to play a role in the operation of commercial trucks. It is applied in various truck systems, including fuel lines, brake systems, and hydraulic systems. By securely clamping tubing, it ensures that these systems operate efficiently and reliably, contributing to the overall performance of the vehicle.

Key Features

This Cummins part is constructed with durable materials, typically including high-strength steel and corrosion-resistant coatings. Its design incorporates a clamping mechanism that provides a strong and consistent grip on the tubing. Unique attributes such as adjustable clamps and easy-to-use installation features enhance its performance and durability, making it suitable for demanding commercial truck applications 2.

Benefits of Using the Cummins 4303123 Tube Clamp

Using the Cummins 4303123 Tube Clamp offers several advantages. It provides improved reliability by ensuring a secure connection that resists vibrations and movement. The clamp is designed for ease of installation, reducing downtime during maintenance. Additionally, its durable construction and corrosion-resistant properties contribute to long-term performance and lower maintenance requirements.

Installation Process

Proper installation of the Cummins 4303123 Tube Clamp involves several steps. First, ensure the tubing is clean and free of debris. Position the clamp around the tubing and use the appropriate tools to tighten it until the desired compression is achieved. It is important to follow manufacturer guidelines to ensure a secure fit and prevent damage to the tubing or clamp.

Troubleshooting Common Issues

Common issues with tube clamps include leaks and improper fitting. To address leaks, inspect the clamp for proper tightness and ensure there is no damage to the tubing. If the clamp is loose or damaged, it should be retightened or replaced. For improper fitting, verify that the tubing size matches the clamp specifications and that the clamp is correctly positioned.

Maintenance Tips

Regular maintenance of the Cummins 4303123 Tube Clamp is important for ensuring long-term performance. Inspect the clamp periodically for signs of wear, corrosion, or damage. Clean the clamp and tubing as needed to remove any buildup that could affect performance. Following these maintenance practices will help maintain the reliability and efficiency of the clamp.

Compatibility and Applications

The Cummins 4303123 Tube Clamp is typically used in various commercial truck systems, including fuel lines, brake systems, and hydraulic systems. It is designed to be compatible with standard tubing sizes and materials commonly used in these applications. Ensuring compatibility with other components is important for optimal performance.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins serves commercial vehicle, industrial, and power generation markets. The company is known for its commitment to reliability, performance, and customer satisfaction, making it a trusted name in the commercial vehicle industry 3.

Role of Part 4303123 Tube Clamp in Engine Systems

The 4303123 Tube Clamp is an essential component in ensuring the secure and efficient operation of various engine systems. Its primary function is to maintain a tight seal and provide structural support for tubing connections, which is vital for the performance and reliability of the engine.

Fuel Manifold Integration

In the context of a fuel manifold, the 4303123 Tube Clamp plays a significant role by securing the connections between the manifold and the fuel lines. This ensures that fuel is distributed evenly to each injector, which is necessary for balanced engine performance. The clamp prevents leaks and maintains consistent fuel pressure, which is essential for optimal combustion and engine efficiency.

Injector Connections

When connecting fuel injectors to the fuel supply lines, the 4303123 Tube Clamp ensures a secure fit. This is important for maintaining the precise fuel delivery required by modern fuel injection systems. A secure connection prevents fuel leaks and ensures that the injectors receive a steady supply of fuel, which is necessary for accurate fuel metering and engine performance.

General Plumbing Applications

In broader plumbing applications within the engine system, the 4303123 Tube Clamp is used to connect various parts of the fuel supply system. Whether it’s connecting the fuel tank to the fuel pump or the fuel pump to the fuel rail, the clamp ensures that all connections are tight and leak-free. This is important for maintaining the integrity of the fuel supply system and ensuring that the engine receives a consistent fuel flow.

Performance and Reliability

The use of the 4303123 Tube Clamp in these applications contributes to the overall performance and reliability of the engine. By ensuring secure and leak-free connections, the clamp helps maintain the engine’s efficiency and reduces the risk of fuel-related issues. This is particularly important in high-performance engines where precise fuel delivery and system integrity are paramount.

Conclusion

In summary, the 4303123 Tube Clamp is a vital component in the engine system, providing the necessary support and sealing for critical connections in the fuel manifold, injectors, and general plumbing applications. Its role in maintaining system integrity and performance cannot be overstated.

-

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩ -

Dixon, J. (2010). Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning.

↩ -

Fijalkowski, B. T. (2011). Automotive Mechatronics Operational and Practical Issues Volume 1. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.