This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

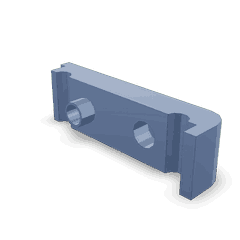

The Cummins 4303126 Tube Clamp is a component designed for use in commercial trucks. It serves to secure and maintain the integrity of tubing systems within these vehicles. A tube clamp is a device used to hold tubing in place, ensuring that connections remain secure and that fluid flow is maintained without leaks. In automotive systems, tube clamps are commonly employed in fuel, coolant, and hydraulic systems, among others 1.

Basic Concepts of Tube Clamps

Tube clamps are designed to provide a secure connection between tubing and fittings. They operate by compressing the tubing against a fitting or another piece of tubing, creating a seal that prevents fluid leakage. Tube clamps typically consist of a band that wraps around the tubing and a mechanism to tighten the band, such as a screw or cam lever. Materials used in tube clamps vary but often include metals like stainless steel for their strength and resistance to corrosion, as well as elastomers for their flexibility and sealing properties 2.

Purpose of the Cummins 4303126 Tube Clamp

This Cummins part plays a role in securing and maintaining the integrity of tubing systems in trucks. By ensuring that tubing connections remain tight and leak-free, it contributes to the proper flow of fluids within the system. This is vital for the performance and reliability of the truck’s systems, as any disruption in fluid flow can lead to decreased efficiency or system failure 3.

Key Features

The 4303126 is characterized by its design and material composition. It is constructed from materials that offer durability and resistance to the harsh conditions found in commercial truck environments. Its design allows for easy installation and adjustment, ensuring a secure fit on various tubing sizes. Additionally, it may feature unique attributes such as a corrosion-resistant coating or a design that minimizes the risk of tubing damage during installation.

Benefits of Using the Cummins 4303126 Tube Clamp

Utilizing this part offers several advantages. It enhances system reliability by providing a secure and leak-free connection. Its design facilitates ease of installation, reducing downtime during maintenance procedures. Furthermore, the clamp’s durability and resistance to environmental factors contribute to lower maintenance requirements and extended service life, ultimately supporting overall truck performance and longevity 4.

Installation and Usage

Proper installation of the 4303126 is crucial for optimal performance. It should be applied according to manufacturer guidelines, ensuring that the tubing is correctly aligned and the clamp is tightened to the specified torque. Careful attention to these steps will help maintain the integrity of the tubing system and ensure efficient fluid flow. Integrating the clamp into existing truck systems requires consideration of the specific application and tubing size to achieve the best results.

Troubleshooting and Maintenance

Common issues with tube clamps include leaks due to improper installation or wear over time. Regular inspection and maintenance can help identify and address these problems before they lead to system failure. Maintenance tips for this Cummins part include checking for signs of wear or corrosion, ensuring the clamp remains securely tightened, and replacing the clamp if it shows signs of damage or if tubing is replaced. Troubleshooting strategies involve verifying the clamp’s installation, assessing the condition of the tubing, and ensuring compatibility with the system’s requirements.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s commitment to excellence is reflected in its wide range of products, which are designed to meet the demanding requirements of commercial applications. Cummins’ dedication to quality ensures that its components, including the 4303126 Tube Clamp, contribute to the reliability and performance of commercial trucks.

Compatibility with Cummins Engines

This part, manufactured by Cummins, is designed to fit seamlessly with several of their engine models. It is crucial for maintaining the integrity of the engine’s cooling system by securing and sealing tubes that transport coolant or other fluids.

QST30 Engine

In the QST30 engine, the 4303126 is used to secure the coolant tubes that run through the engine block. Its precise fit ensures that there are no leaks, which is essential for maintaining optimal engine temperature and preventing overheating.

CM2350 and T101 Engines

For the CM2350 and T101 engines, the 4303126 serves a similar purpose. These engines, often found in heavy-duty applications, require robust and reliable components to withstand the rigors of continuous operation. The Tube Clamp ensures that the coolant and other fluid pathways remain sealed, which is critical for the longevity and performance of these engines.

The 4303126 is engineered to provide a tight and secure fit, preventing any movement or loosening over time. This is particularly important in high-stress environments where the engine is subjected to varying temperatures and pressures.

Role of Part 4303126 Tube Clamp in Engine Systems

This part is an essential component in ensuring the secure and efficient connection of various elements within engine systems. Its primary function is to maintain the integrity of fuel lines and other fluid pathways, which is vital for the overall performance and reliability of the engine.

In the context of a fuel manifold, the Tube Clamp ensures that the connections between the manifold and the fuel lines are tight and leak-free. This is important for maintaining consistent fuel pressure and flow, which directly impacts the engine’s performance. A secure connection prevents fuel leaks, which could lead to dangerous situations and inefficient fuel delivery.

When it comes to injectors, the Tube Clamp plays a role in securing the fuel lines that supply the injectors. Proper clamping ensures that the fuel reaches the injectors under the correct pressure, allowing for precise fuel delivery to the combustion chambers. This precision is essential for optimal engine performance and fuel efficiency.

In terms of plumbing within the engine system, the Tube Clamp is used to connect various parts of the fuel supply lines. Whether it’s connecting the fuel tank to the fuel pump or the fuel pump to the fuel rail, the Tube Clamp ensures that these connections are robust and resistant to vibrations and movements that occur during engine operation.

Overall, the use of Part 4303126 Tube Clamp in engine systems is about ensuring secure, leak-free connections that contribute to the efficient and reliable operation of the engine. Its application across different components like the fuel manifold, injectors, and fuel supply lines underscores its importance in maintaining the performance and safety of the engine.

Conclusion

The Cummins 4303126 Tube Clamp is a critical component in the maintenance and operation of commercial truck engine systems. Its role in securing and maintaining the integrity of tubing systems ensures efficient fluid flow and system reliability. The clamp’s design and material composition contribute to its durability and resistance to environmental factors, supporting overall truck performance and longevity. Proper installation, regular maintenance, and troubleshooting are essential for maximizing the benefits of this part in commercial truck applications.

-

Sheng, G. (2012). Vehicle Noise, Vibration and Sound Quality. SAE International.

↩ -

Viskup, R. (2020). Diesel and Gasoline Engines. IntechOpen.

↩ -

Majewski, A., & Jaskelainen, H. (2023). Diesel Emissions and Their Control: Second Edition. SAE International.

↩ -

Ribbens, W. B. (2003). Understanding Automotive Electronics. Elsevier Science.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.