This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

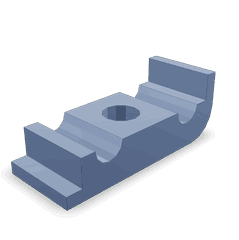

The Cummins 4303129 Tube Clamp is a component designed to secure tubing systems in commercial trucks. Its role is significant in maintaining the integrity and efficiency of various truck systems by ensuring that tubing connections remain secure and leak-free.

Basic Concepts of Tube Clamps

Tube clamps are devices used to hold tubing in place, providing a secure connection without the need for welding or soldering. They are widely used in automotive and industrial applications to fasten tubing systems, allowing for easy assembly, disassembly, and maintenance. Tube clamps function by compressing the tubing between two surfaces, creating a tight seal that prevents leaks and ensures the tubing remains in the desired position 1.

Purpose of the Cummins 4303129 Tube Clamp

This Cummins part is specifically designed to play a role in securing tubing within various truck systems. It is applied in fuel lines, coolant systems, and other fluid transport applications where secure and reliable connections are required. By maintaining a tight seal, the clamp helps ensure that the fluid systems operate efficiently and without leaks.

Key Features

This part features a durable material composition, typically made from high-strength steel or stainless steel, which provides resistance to corrosion and wear. Its design includes a band that wraps around the tubing and a screw mechanism that tightens the band, creating a secure fit. Unique attributes such as adjustable sizing and ease of installation enhance its functionality, allowing it to accommodate various tubing diameters and be quickly installed or removed as needed.

Benefits of Using the Cummins 4303129 Tube Clamp

This part offers several advantages. Its durable construction ensures long-term reliability, while its design allows for easy installation without specialized tools. The clamp provides a secure fit that helps prevent leaks, contributing to the overall efficiency and safety of the truck’s fluid systems.

Installation Process

To install the Cummins 4303129 Tube Clamp, first, ensure the tubing is clean and free of debris. Position the clamp around the tubing, ensuring it is centered. Use the provided screw to tighten the band, compressing the tubing until a secure fit is achieved. It is important to tighten the clamp evenly to avoid damaging the tubing or creating an uneven seal.

Troubleshooting Common Issues

Common issues with tube clamps include leaks and loose fittings. To address leaks, inspect the clamp for proper tightness and ensure the tubing is not damaged. If the fitting is loose, re-tighten the clamp, ensuring even pressure is applied. If problems persist, the clamp or tubing may need to be replaced.

Maintenance Tips

Regular maintenance of this part involves periodic inspection for signs of wear or corrosion. Cleaning the clamp and tubing connections can help prevent buildup that may affect performance. It is also important to check the tightness of the clamp at regular intervals to ensure it remains secure.

Compatibility and Applications

This Cummins part is designed for use in various commercial truck systems, including fuel and coolant lines. It is compatible with standard tubing sizes used in these applications, ensuring it can be integrated into existing systems without issues.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a strong reputation in the commercial vehicle industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and history of excellence make it a trusted name in the automotive and heavy-duty truck sectors.

Tube Clamp 4303129 Compatibility with Cummins Engines

The Tube Clamp part number 4303129, manufactured by Cummins, is designed to fit seamlessly with several of their engine models. This clamp is a critical component in ensuring the integrity of the engine’s cooling system and other fluid pathways.

QST30 and CM2350 Engines

The Tube Clamp 4303129 is specifically engineered to integrate with the QST30 and CM2350 engines. These engines are known for their robust design and efficiency, often used in heavy-duty applications. The clamp’s precision fit ensures that it maintains a secure seal, preventing any leaks that could compromise engine performance.

T101 Engine

Similarly, the Tube Clamp 4303129 is compatible with the T101 engine. This engine model is also designed for durability and reliability, making it a popular choice in various industrial applications. The clamp’s design allows it to fit snugly around the tubes, providing a reliable connection that can withstand the rigors of continuous operation.

Common Features Across Models

While the QST30, CM2350, and T101 engines may have distinct specifications and applications, the Tube Clamp 4303129 is engineered to fit all these models with ease. This compatibility is achieved through meticulous design and quality manufacturing processes, ensuring that the clamp performs optimally across different engine types.

By using the Tube Clamp 4303129, engine operators can maintain the integrity of their cooling systems and other fluid pathways, contributing to the overall efficiency and longevity of their engines.

Role of Part 4303129 Tube Clamp in Engine Systems

The 4303129 Tube Clamp is an integral component in the assembly and maintenance of various engine systems, particularly those involving fluid dynamics and fuel delivery. Its primary function is to secure tubing connections, ensuring a leak-free and stable system.

Integration with Fuel Manifold

In the context of a fuel manifold, the 4303129 Tube Clamp is employed to connect the manifold to the fuel supply lines. This secure connection is essential for maintaining consistent fuel pressure and flow, which directly impacts engine performance. The clamp ensures that the tubing remains firmly in place, preventing any disconnections that could lead to fuel leaks or inconsistent fuel delivery.

Connection to Injectors

When interfacing with fuel injectors, the 4303129 Tube Clamp plays a significant role in securing the fuel lines to the injector ports. This connection is vital for precise fuel metering, as any loose connection could result in fuel leakage or improper fuel atomization. The clamp’s reliable hold ensures that the injectors receive a steady and controlled fuel supply, optimizing combustion efficiency and overall engine performance.

Role in Plumbing and Fuel Supply Systems

In the broader plumbing and fuel supply systems of an engine, the 4303129 Tube Clamp is used to connect various components such as filters, regulators, and sensors to the main fuel lines. This application ensures that all parts of the fuel system are securely linked, promoting efficient fuel flow and reducing the risk of leaks. The clamp’s durability and ease of installation make it a preferred choice for maintaining the integrity of these critical connections.

Enhancing Overall Performance

By ensuring secure and leak-free connections across the fuel system, the 4303129 Tube Clamp contributes to the overall performance and reliability of the engine. Its role in maintaining consistent fuel pressure and flow is fundamental to achieving optimal engine operation, highlighting the importance of this component in engine systems 2.

Conclusion

The Cummins 4303129 Tube Clamp is a vital component in the maintenance and efficiency of commercial truck systems. Its durable construction, ease of installation, and secure fit make it an essential part for ensuring leak-free and stable connections in fuel and coolant systems. Regular maintenance and proper installation are key to maximizing the benefits of this part, contributing to the overall performance and longevity of the engine systems it supports.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.