This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

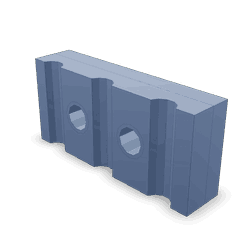

The Cummins 4310981 Tube Clamp is a component designed for use in commercial truck operations. It serves to secure and maintain the integrity of tubing systems within these vehicles. This clamp is integral to ensuring that the various fluid and air lines in a truck’s system remain properly connected and sealed, contributing to the overall efficiency and safety of the vehicle 3.

Basic Concepts of Tube Clamps

Tube clamps are mechanical devices used to hold tubing in place and ensure a secure connection. They function by applying pressure around the tubing, creating a seal that prevents leaks and maintains the structural integrity of the system. In automotive and industrial settings, tube clamps are commonly used in fuel lines, brake systems, and pneumatic systems, among others 4.

Purpose of the Cummins 4310981 Tube Clamp

The Cummins 4310981 Tube Clamp plays a role in securing and maintaining the integrity of tubing systems in trucks. It is designed to provide a reliable connection that can withstand the vibrations and movements typical in commercial truck operations. By ensuring that tubing remains securely attached, this clamp helps maintain the efficiency and safety of the vehicle’s systems 1.

Key Features

The Cummins 4310981 Tube Clamp is constructed from durable materials, ensuring it can withstand the rigors of commercial truck use. Its design includes features that enhance its performance and durability, such as a robust clamping mechanism that provides a secure hold on the tubing. Additionally, the clamp is designed to be easy to install and remove, facilitating maintenance and repair processes 2.

Benefits of Using the Cummins 4310981 Tube Clamp

Using the Cummins 4310981 Tube Clamp offers several advantages. It provides improved safety by ensuring that tubing connections remain secure, reducing the risk of leaks and system failures. The clamp also contributes to the reliability and efficiency of the truck’s systems by maintaining proper connections and seals. Its durable construction ensures longevity, reducing the need for frequent replacements 3.

Installation Process

To install the Cummins 4310981 Tube Clamp, first, ensure that the tubing is clean and free of any debris. Position the clamp around the tubing and use the appropriate tools to tighten it securely. It is important to follow the manufacturer’s guidelines for torque specifications to ensure a proper seal without over-tightening, which could damage the tubing 4.

Maintenance and Care

Regular maintenance of the Cummins 4310981 Tube Clamp is important to ensure its longevity and optimal performance. This includes periodic inspection for signs of wear or damage and cleaning the clamp and tubing to remove any buildup that could affect the seal. If any issues are detected, the clamp should be repaired or replaced as necessary 1.

Troubleshooting Common Issues

Common issues with tube clamps include leaks and loose connections. These can often be resolved by tightening the clamp or replacing it if it is damaged. Regular inspections can help identify these issues early, allowing for timely repairs and preventing more serious problems 2.

Compatibility and Applications

The Cummins 4310981 Tube Clamp is designed for use in a variety of commercial truck applications. It is compatible with different types of tubing and is commonly used in fuel, brake, and pneumatic systems. Its versatility makes it a valuable component in maintaining the integrity of these systems 3.

Safety Considerations

When installing, maintaining, or troubleshooting the Cummins 4310981 Tube Clamp, it is important to observe safety practices. This includes wearing appropriate personal protective equipment, ensuring the truck is properly secured before beginning work, and following all manufacturer guidelines and safety instructions 4.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company offers a wide range of products designed to meet the needs of various applications, from on-highway to off-highway and industrial uses 1.

Role of Part 4310981 Tube Clamp in Engine Systems

The 4310981 Tube Clamp is an essential component in securing and maintaining the integrity of various tubing systems within engine assemblies. Its application spans across multiple subsystems, ensuring efficient operation and durability 2.

Integration with Fuel Systems

In fuel delivery systems, the 4310981 Tube Clamp is utilized to secure the injector fuel supply tube. This ensures a leak-free connection between the fuel rail and the injectors, maintaining consistent fuel pressure and delivery. The clamp’s reliable hold prevents fuel leaks, which could otherwise lead to performance issues or safety hazards 3.

Camshaft and Gear Assembly

Within the camshaft and gear assembly, the Tube Clamp plays a role in securing lubrication lines. These lines are vital for delivering oil to moving parts, reducing friction, and enhancing the longevity of the camshaft and associated gears. A secure connection ensures that oil flow is uninterrupted, contributing to the overall performance and reliability of the engine 4.

Turbocharger Systems

In turbocharged engines, the 4310981 Tube Clamp is employed to fasten vent tubes and plumbing lines. These tubes are responsible for managing pressure relief and maintaining optimal turbocharger operation. By ensuring these connections are tight and secure, the Tube Clamp helps in preventing pressure leaks, which could impair turbocharger efficiency and engine performance 1.

General Plumbing Applications

Across various engine plumbing applications, the Tube Clamp is instrumental in connecting and securing different types of tubing. Whether it’s for coolant lines, vacuum hoses, or other fluid pathways, the clamp provides a robust solution to maintain system integrity under varying operating conditions 2.

Performance Parts

When upgrading to performance parts, the 4310981 Tube Clamp is often used to enhance the security of aftermarket tubing. Performance enhancements frequently involve modifications to fuel, oil, and coolant systems, where the Tube Clamp ensures that these high-performance components remain firmly in place, even under increased stress and temperature conditions 3.

Conclusion

The Cummins 4310981 Tube Clamp is a versatile and reliable component that contributes to the efficient and safe operation of various engine systems by ensuring secure and leak-free connections. Its application across multiple subsystems underscores its importance in maintaining engine efficiency and safety 4.

-

Asef, Pedram, Sanjeevikumar Padmanaban, and Andrew Lapthorn. Modern Automotive Electrical Systems. Wiley, 2022.

↩ ↩ ↩ ↩ -

Kershaw, John F. SAE International’s Dictionary for Automotive Engineers. SAE International, 2023.

↩ ↩ ↩ ↩ -

Robinson, Alan, and Andrew Livesey. The Repair of Vehicle Bodies Fifth Edition. Elsevier, 2006.

↩ ↩ ↩ ↩ ↩ -

Rajamani, Rajesh. Vehicle Dynamics and Control. Springer, 2005.

↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.