This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

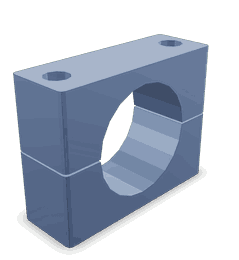

The Cummins 4322978 Tube Clamp is a component designed to secure tubing systems in commercial trucks. Its role is significant in maintaining the integrity and efficiency of various truck systems by ensuring that tubing connections remain secure under operational conditions.

Basic Concepts of Tube Clamps

Tube clamps are devices used to hold tubing in place, providing a secure connection without the need for welding or soldering 1. In automotive applications, they are crucial for maintaining the structural integrity of fluid and air systems. Tube clamps function by compressing the tubing against a surface, creating a tight seal that prevents leaks and ensures consistent flow.

Purpose of the Cummins 4322978 Tube Clamp

The Cummins 4322978 Tube Clamp is specifically designed to secure tubing in commercial truck systems. It plays a role in various applications, including fuel lines, brake systems, and hydraulic lines. By providing a reliable connection, it helps maintain the performance and safety of these critical systems 2.

Key Features

The Cummins 4322978 Tube Clamp is constructed from high-quality materials, ensuring durability and resistance to corrosion 3. Its design includes a band that wraps around the tubing and a screw mechanism that tightens to create a secure fit. Unique characteristics such as adjustable sizing and ease of installation enhance its performance in various applications.

Benefits of Using the Cummins 4322978 Tube Clamp

Using the Cummins 4322978 Tube Clamp offers several advantages. Its robust construction ensures long-lasting durability, while the ease of installation reduces downtime during maintenance. The reliable clamping mechanism provides a secure connection, minimizing the risk of leaks and ensuring consistent system performance 4.

Installation Process

To install the Cummins 4322978 Tube Clamp, first, ensure the tubing is clean and free of debris. Position the clamp around the tubing and use the provided screw to tighten it until the desired tension is achieved. Tools required may include a wrench for tightening. Follow best practices to ensure a secure fit, such as checking for even pressure distribution around the tubing.

Maintenance and Troubleshooting

Regular maintenance of the Cummins 4322978 Tube Clamp involves inspecting for signs of wear or corrosion. Common issues include loosening of the clamp, which can be addressed by re-tightening. If corrosion is detected, consider replacing the clamp to maintain system integrity. Troubleshooting tips include ensuring proper installation techniques and using the correct torque specifications.

Compatibility and Applications

The Cummins 4322978 Tube Clamp is designed for use in various commercial truck systems, including fuel, brake, and hydraulic lines. Compatibility with other components is ensured through precise engineering standards. It is important to verify fitment with specific truck models and systems to ensure optimal performance.

Safety Considerations

When installing or maintaining the Cummins 4322978 Tube Clamp, observe safety practices such as wearing protective gloves and eyewear. Ensure the truck is parked on a level surface and the engine is off to prevent accidents. Follow manufacturer guidelines for torque specifications to avoid over-tightening, which can damage the tubing or clamp.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins has established a reputation for reliability and performance in the commercial truck industry. The company’s dedication to advancing technology ensures that its products, including the Cummins 4322978 Tube Clamp, meet the high standards required for modern commercial vehicles.

Tube Clamp 4322978 Compatibility with Cummins Engines

The Tube Clamp part number 4322978, manufactured by Cummins, is designed to fit seamlessly with several of their engine models. This part is crucial for maintaining the integrity of the engine’s tubing systems, ensuring that connections remain secure and leak-free.

QSK50 Series

The Tube Clamp 4322978 is compatible with the following QSK50 engines:

- QSK50 CM2150 MCRS

- QSK50 CM2350 K108

These engines benefit from the clamp’s ability to secure tubing in high-stress environments, ensuring that the engine’s performance remains unaffected by potential leaks or disconnections.

QSK60 Series

The Tube Clamp 4322978 also fits the following QSK60 engine:

- QSK60 G CM2358 K110

In this engine, the clamp provides essential support for the tubing systems, maintaining the necessary pressure and flow required for optimal engine operation.

QST30 Series

The Tube Clamp 4322978 is also suitable for the following QST30 engine:

- QST30 CM2350 T101

For this engine, the clamp ensures that the tubing connections remain tight and secure, preventing any potential issues that could arise from loose fittings.

By ensuring that the Tube Clamp 4322978 is properly installed, engine operators can maintain the reliability and efficiency of their Cummins engines, knowing that their tubing systems are well-protected.

Role of Part 4322978 Tube Clamp in Engine Systems

The 4322978 Tube Clamp is an essential component in the secure and efficient operation of various engine systems. Its primary function is to ensure a tight and reliable connection between tubes and fittings, which is vital for maintaining system integrity and performance.

In the arrangement of engine components, the Tube Clamp plays a significant role in securing tubes that connect different parts of the engine. This includes connections in the fuel transfer kit and the fuel transfer right-hand engine kit, where it ensures that fuel lines are properly sealed to prevent leaks and maintain consistent fuel flow.

Within the fuel control system, the Tube Clamp is used to connect tubes that deliver fuel to the engine’s combustion chambers. This connection is important for precise fuel metering and delivery, which directly impacts engine performance and efficiency.

In the plumbing of the charge air bypass system, the Tube Clamp secures the tubes that route air around the turbocharger. This ensures that the air bypass functions correctly, helping to manage engine boost and prevent over-pressurization.

The Tube Clamp is also integral in the service kit for various engine systems. It is used to replace or install tubes in the pressure regulator valve and pressure regulator, ensuring these components operate within specified parameters to maintain engine stability and performance.

Additionally, in the auxiliary cooling system, the Tube Clamp secures the tubes that circulate coolant throughout the engine. This is important for thermal management, helping to keep engine temperatures within optimal ranges to prevent overheating and component failure.

Overall, the 4322978 Tube Clamp is a versatile and reliable component that enhances the functionality and safety of multiple engine systems by providing secure and leak-free connections.

Conclusion

The Cummins 4322978 Tube Clamp is a vital component in the maintenance and operation of commercial truck systems. Its robust construction, ease of installation, and reliable clamping mechanism make it an essential part for ensuring the integrity and efficiency of various engine systems. By understanding its key features, benefits, and proper installation and maintenance procedures, users can ensure optimal performance and safety in their vehicles.

-

Automotive Heating Ventilation and Air Conditioning, Quansheng Zhan, Shengbo Eben, Li Kun Deng, Jones Bartlett Learning, 2018

↩ -

Fundamentals of Medium-Heavy Duty Diesel Engines, Gus Wright, Jones & Bartlett Learning, 2015

↩ -

Dictionary of Mechanical Engineering, D. K. Singh, Springer Nature, 2024

↩ -

Fundamentals of Motor Vehicle Technology Book 1 6th Edition, Alma Hillier, Oxford University Press, 2014

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.