This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

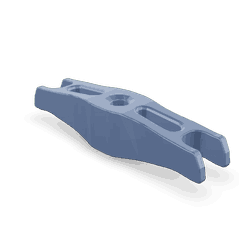

The Cummins Injector Clamp, part number 4325371, is a component designed for use in the fuel injection systems of commercial trucks. Cummins, a well-established name in the commercial truck industry, produces a range of parts and systems that contribute to the efficient and reliable operation of heavy-duty vehicles. This Cummins part is significant in ensuring the proper functioning of the fuel injection system, which is vital for the overall performance and efficiency of commercial trucks.

Purpose and Function

The Injector Clamp 4325371 plays a role in the fuel injection system by securing the injector in place. This ensures that the injector remains stable during operation, which is important for consistent fuel delivery. Proper fuel delivery is necessary for optimal engine performance, as it ensures that the correct amount of fuel is delivered at the right time. The clamp helps maintain the integrity of the fuel injection process by preventing the injector from moving or vibrating excessively, which could lead to fuel delivery issues 1.

Key Features

The Injector Clamp 4325371 is designed with specific characteristics that enhance its performance and durability. It is constructed from materials that can withstand the high temperatures and pressures present in the fuel injection system. The design of the clamp allows for a secure fit around the injector, which is important for maintaining the injector’s position and ensuring reliable fuel delivery. Additionally, the clamp is engineered to be compatible with various injector types, providing versatility in its applications 2.

Benefits

Using the Injector Clamp 4325371 offers several advantages. It contributes to improved fuel efficiency by ensuring that the injector is properly secured and that fuel delivery is consistent. This can lead to better engine performance, as the engine receives a steady supply of fuel. The clamp’s durable construction allows it to operate reliably in harsh conditions, which is common in the commercial truck industry. This reliability helps reduce the likelihood of fuel system failures and the need for frequent maintenance 3.

Installation Process

Installing the Injector Clamp 4325371 involves several steps to ensure it is properly secured and functions as intended. The process begins with ensuring that the injector is clean and free of any debris. The clamp is then positioned around the injector and tightened to the manufacturer’s specifications using the appropriate tools. It is important to follow the installation instructions carefully to avoid over-tightening, which could damage the injector or the clamp.

Maintenance and Troubleshooting

Regular maintenance of the Injector Clamp 4325371 is important to ensure its longevity and optimal performance. This includes periodic inspections to check for signs of wear or damage. If the clamp shows signs of deterioration, it should be replaced to prevent potential fuel system issues. Common issues that may arise include loose clamps, which can lead to inconsistent fuel delivery. Troubleshooting these issues typically involves re-tightening the clamp or replacing it if necessary.

Compatibility and Applications

The Injector Clamp 4325371 is designed for use with specific types of engines and truck models. It is particularly beneficial in applications where reliable fuel delivery is crucial for engine performance. The clamp’s compatibility with various injector types makes it a versatile component for different fuel injection systems.

Safety Considerations

When handling and installing the Injector Clamp 4325371, it is important to observe safety guidelines to prevent accidents and ensure safe operation. This includes wearing appropriate personal protective equipment and following the manufacturer’s instructions for installation. Additionally, it is important to ensure that the fuel system is depressurized before beginning any work to avoid the risk of fuel spray, which can be hazardous.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for producing high-quality components and systems for the commercial truck industry. The company’s product range includes engines, powertrain components, and aftermarket parts, all of which are designed to meet the demanding requirements of heavy-duty applications.

Cummins Injector Clamp 4325371 Compatibility

The Cummins Injector Clamp part number 4325371 is a critical component designed to secure the fuel injectors in various engine configurations. This clamp ensures that the injectors are properly aligned and tightly fastened, which is essential for maintaining optimal fuel delivery and engine performance.

ISV (Nissan) Engines

The Cummins Injector Clamp 4325371 is compatible with several ISV (Nissan) engines. These engines are known for their reliability and efficiency, often used in heavy-duty applications. The clamp is engineered to fit seamlessly with the injectors in these engines, ensuring a secure and leak-free connection.

-

ISV Engine Models: The injector clamp is designed to work with various ISV engine models, providing a standardized solution for securing injectors across different variants. This compatibility ensures that technicians and mechanics can easily replace or maintain injector clamps without needing specific parts for each engine model.

-

Installation Process: The installation of the Cummins Injector Clamp 4325371 in ISV engines involves aligning the clamp with the injector and tightening it to the manufacturer’s specified torque. This process is crucial for maintaining the integrity of the fuel system and preventing fuel leaks, which can lead to performance issues and potential safety hazards.

-

Performance Impact: Properly installed injector clamps contribute to the overall efficiency and longevity of the engine. By ensuring that the injectors are securely fastened, the clamp helps maintain consistent fuel delivery, which is vital for the engine’s performance and longevity.

Role of Part 4325371 Injector Clamp in Engine Systems

The injector clamp, specifically part 4325371, is an essential component in the orchestration of fuel delivery within engine systems. Its primary function is to secure the injector in place, ensuring a stable and precise fuel injection process. This stability is vital for maintaining the injector’s alignment and operational integrity, directly influencing the engine’s performance and efficiency.

In the context of a long block kit, the injector clamp plays a significant role. It ensures that the injector is correctly positioned within the engine block, facilitating optimal fuel atomization and distribution. This, in turn, contributes to the overall performance of the engine by promoting a more complete and efficient combustion process.

When considering the camshaft, the injector clamp’s role becomes even more apparent. The camshaft dictates the timing of the fuel injection, and the clamp ensures that the injector is in the correct position to respond to these timing cues. This synchronization is key to achieving the desired engine performance, as it allows for precise fuel delivery in harmony with the engine’s mechanical movements.

Conclusion

In summary, the Cummins Injector Clamp 4325371 is a versatile and essential component for securing fuel injectors in ISV (Nissan) engines. Its compatibility with various engine models and straightforward installation process make it a reliable choice for maintaining the integrity of the fuel system. The clamp’s role in ensuring stable and precise fuel delivery is crucial for the efficient operation and longevity of the engine.

-

Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition, Robert Bosch GmbH, Springer Vieweg, 2007.

↩ -

Energy Efficiency of Vehicles, Douglas R Carroll, SAE International, 2020.

↩ -

Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body, David C Barton and John D Fieldhouse, Elsevier, 2009.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.