4329723

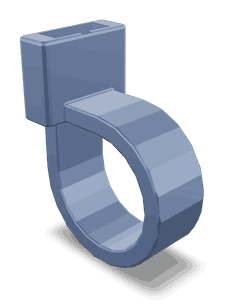

Wire Tie Clamp

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4329723 Wire Tie Clamp, manufactured by Cummins, is a component designed for use in commercial trucks. Cummins, a well-established name in the commercial truck industry, produces a range of parts and systems aimed at enhancing the performance and reliability of heavy-duty vehicles. This part is specifically engineered to assist in the organization and protection of wiring systems within these trucks.

Basic Concepts of Wire Tie Clamps

Wire tie clamps are devices used to secure and organize wires and cables in various automotive and industrial applications. They function by wrapping around bundles of wires and cables, holding them together and preventing them from moving or vibrating excessively. This not only helps in maintaining a tidy and organized wiring system but also protects the wires from potential damage due to abrasion or environmental factors 1.

Purpose of the 4329723 Wire Tie Clamp in Truck Operations

In the context of commercial trucks, the 4329723 Wire Tie Clamp plays a role in the operation and maintenance by securing and organizing the wiring systems. This organization is important for several reasons: it reduces the risk of wires becoming tangled or damaged, it aids in easier troubleshooting and maintenance, and it contributes to the overall safety and efficiency of the vehicle’s electrical system 2.

Key Features

The 4329723 Wire Tie Clamp is characterized by several key features that enhance its functionality and durability. It is made from materials that offer resistance to corrosion and wear, ensuring longevity in the demanding environment of a commercial truck. The design of the clamp allows for easy installation and adjustment, accommodating various wire sizes and configurations. Additionally, it features a locking mechanism that secures the clamp in place once tightened, providing a stable and reliable hold on the wires 3.

Benefits of Using the 4329723 Wire Tie Clamp

Utilizing the 4329723 Wire Tie Clamp offers several advantages. It improves wire management within the truck, leading to a more organized and accessible wiring system. This organization can enhance safety by reducing the likelihood of wire damage and electrical faults. Furthermore, efficient wire management can lead to cost savings through streamlined maintenance processes and reduced downtime 4.

Installation Process

Installing the 4329723 Wire Tie Clamp involves a few straightforward steps. First, identify the section of wires that requires securing. Then, place the clamp around the wires, ensuring it is positioned correctly. Using the appropriate tool, tighten the clamp until the wires are held securely in place. It is important to ensure that the clamp is not overtightened, as this could damage the wires. Following the manufacturer’s guidelines for installation will help ensure the clamp is used effectively and safely.

Troubleshooting Common Issues

Common issues with wire tie clamps may include loosening over time or difficulty in securing wires of varying sizes. To address these problems, regular inspections should be conducted to ensure the clamps remain tight and secure. If a clamp appears loose, it may need to be retightened or replaced. For wires of different sizes, selecting the appropriate size of clamp or using additional clamps may be necessary to achieve a secure fit.

Maintenance Tips

Regular maintenance of the 4329723 Wire Tie Clamp involves inspecting it for signs of wear or damage, ensuring it remains securely fastened, and cleaning it as needed to remove any dirt or debris. If the clamp shows significant wear or if the wires it secures are damaged, it may be necessary to replace it to maintain the integrity of the wiring system.

Compatibility and Applications

The 4329723 Wire Tie Clamp is designed for use in various truck models and systems, demonstrating its versatility and widespread applicability within the commercial truck industry.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and global presence underscore its leadership in the power generation and transportation sectors.

Wire Tie Clamp 4329723 Compatibility with Cummins Engines

The Wire Tie Clamp 4329723, manufactured by Cummins, is designed to be compatible with a variety of Cummins engine models. This part is essential for securing wires and cables in place, ensuring they remain organized and do not interfere with engine components.

B6.7 CM2670 Engines

The Wire Tie Clamp 4329723 is suitable for use with the B6.7 CM2670 engines, including the B6.7 CM2670 B153B and B6.7 CM2670 B153B variants. These engines are known for their robust performance and reliability, making them a popular choice in various applications.

L9 CM2670 Engines

Similarly, the L9 CM2670 engines, such as the L9 CM2670 L128B, are compatible with the Wire Tie Clamp 4329723. These engines are designed to deliver high efficiency and power, making them ideal for demanding industrial and commercial applications.

QSK95 CM2350 Engines

The Wire Tie Clamp 4329723 is also compatible with the QSK95 CM2350 K113 engine. This engine is engineered for heavy-duty applications, providing exceptional durability and performance.

X11, X12, and X13 CM2670 Engines

The Wire Tie Clamp 4329723 fits seamlessly with the X11 CM2670 X126B, X12 CM2670 X121B, and X13 CM2670 X122B engines. These engines are part of the Cummins X Series, known for their versatility and adaptability in various operational environments.

Role of Part 4329723 Wire Tie Clamp in Engine Systems

The 4329723 Wire Tie Clamp is an essential component in the securement and organization of various wiring systems within engine assemblies. Its application spans across multiple subsystems, ensuring that wires are neatly bundled and protected from potential damage.

In the aftertreatment device and aftertreatment system, the Wire Tie Clamp is utilized to manage the complex network of sensors and control wires. This ensures that the catalytic converter and other aftertreatment components operate efficiently by maintaining the integrity and position of the wiring.

For the noise reduction device, the clamp plays a part in securing wires that are often exposed to vibrations. By keeping these wires organized and taut, it helps in reducing the risk of wire fatigue and potential failure, which could otherwise lead to increased noise levels or performance issues.

In the context of plumbing and the fuel filter rail base, the Wire Tie Clamp is employed to bundle and secure wires that run alongside fuel lines. This not only protects the wires from physical damage but also prevents any interference with the fuel system components.

Additionally, when attached to a sensor bracket, the clamp ensures that the wiring connected to various sensors remains in place. This is particularly important for maintaining the accuracy and reliability of sensor readings, which are vital for the engine’s performance and emissions control.

Overall, the 4329723 Wire Tie Clamp contributes to the durability and reliability of engine systems by providing a simple yet effective solution for wire management.

Conclusion

The 4329723 Wire Tie Clamp by Cummins is a vital component in the maintenance and operation of commercial trucks. Its role in securing and organizing wiring systems enhances safety, efficiency, and reliability. With its compatibility across various Cummins engine models, this part ensures that wires remain protected and in place, contributing to the overall performance of the vehicle.

-

Schneider, W.-H. (2016). Pistons and Engine Testing. Springer Nature.

↩ -

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

Dixon, J. (2014). Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning.

↩ -

Thompson, R. (2019). Automotive Maintenance: Light Repair. Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.