This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

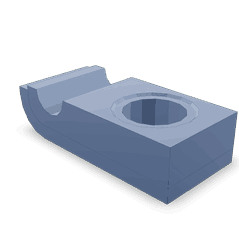

The Cummins 4357773 Tube Clamp is a component designed for use in commercial truck maintenance and operation. It serves a specific function within the truck’s systems, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and significance is vital for maintaining the high performance standards expected in commercial trucking.

Basic Concepts of Tube Clamps

Tube clamps are mechanical fasteners used to secure tubing in various applications. They function by compressing the tubing against a fixed surface, creating a secure and leak-proof connection. In automotive and industrial settings, tube clamps are employed to join sections of tubing, ensuring the integrity of fluid and gas transport systems. Their design allows for easy installation and removal, making them a popular choice for applications requiring frequent adjustments or maintenance 1.

Purpose of the Cummins 4357773 Tube Clamp

The Cummins 4357773 Tube Clamp plays a role in securing tubing within commercial truck systems. It is applied in various truck systems where tubing connections are necessary, ensuring that fluids and gases are transported efficiently and without leaks. Its design is tailored to meet the demands of commercial truck operations, providing a reliable connection in environments where vibrations and harsh conditions are common 2.

Key Features

The Cummins 4357773 Tube Clamp is characterized by several key features that enhance its performance. It is constructed from durable materials, ensuring longevity and resistance to corrosion. The design includes elements that facilitate easy installation and adjustment, allowing for quick changes or repairs. Additionally, the clamp may feature unique attributes such as a locking mechanism to prevent loosening over time, contributing to its reliability in demanding applications 3.

Benefits

Using the Cummins 4357773 Tube Clamp offers several advantages. Its durable construction ensures long-term performance, reducing the need for frequent replacements. The ease of installation simplifies maintenance procedures, allowing for efficient repairs and adjustments. Furthermore, its reliability in harsh operating conditions makes it a suitable choice for commercial trucks, where durability and performance are paramount 4.

Installation Process

Installing the Cummins 4357773 Tube Clamp involves several steps to ensure a secure and leak-proof connection. Begin by positioning the clamp around the tubing, ensuring it is aligned correctly. Use the appropriate tools to tighten the clamp, applying even pressure to avoid damaging the tubing. Verify the connection by checking for leaks or looseness, making adjustments as necessary. Additional components, such as gaskets or spacers, may be required depending on the specific application.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 4357773 Tube Clamp, regular maintenance is recommended. Periodically check the clamp for signs of wear or corrosion, and clean it as needed to remove any debris or buildup. Ensure that the clamp remains securely tightened, making adjustments if loosening is detected. Following these maintenance tips will help maintain the integrity of the tubing connections in your commercial truck.

Troubleshooting Common Issues

Common issues with the Cummins 4357773 Tube Clamp may include leaks, loosening, or corrosion. To address these problems, first, identify the source of the issue. For leaks, check the clamp’s tightness and the condition of the tubing. If the clamp has loosened, tighten it using the appropriate tools. In cases of corrosion, clean the affected area and consider applying a protective coating to prevent further damage. Regular inspections can help identify and resolve these issues before they lead to more significant problems.

Safety Considerations

When installing or maintaining the Cummins 4357773 Tube Clamp, it is important to observe several safety guidelines. Ensure that the truck is parked on a level surface and the engine is turned off to prevent accidental movement. Use the appropriate personal protective equipment, such as gloves and safety glasses, to protect yourself from injury. Follow the manufacturer’s instructions for installation and maintenance to avoid damaging the clamp or the tubing. By adhering to these safety considerations, you can perform maintenance tasks efficiently and safely.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. Their product range includes components and systems designed to enhance the performance, efficiency, and reliability of commercial vehicles. Cummins’ commitment to excellence and customer satisfaction has made them a trusted name in the industry.

Compatibility with Cummins Engines

This part is designed to fit seamlessly with a range of Cummins engines. It is crucial for maintaining the integrity of the engine’s cooling system by securing and sealing tubes and hoses.

QST30 Engine

The Tube Clamp 4357773 is compatible with the QST30 engine, ensuring that the cooling system components are properly fastened and sealed. This compatibility is essential for maintaining optimal engine performance and preventing leaks.

CM2350 and T101 Engines

Similarly, the Tube Clamp 4357773 is also suitable for use with the CM2350 and T101 engines. These engines benefit from the secure fit and reliable sealing provided by this part, ensuring that the cooling system operates efficiently and without leaks.

By using the Tube Clamp 4357773, technicians and engineers can ensure that the cooling system components are properly secured, contributing to the overall reliability and longevity of the engines.

Role of Part 4357773 Tube Clamp in Engine Systems

The 4357773 Tube Clamp is an essential component in various engine systems, ensuring secure and efficient connections across different applications.

Plumbing Systems

In plumbing applications, the 4357773 Tube Clamp provides a reliable means to connect pipes and hoses, facilitating the smooth transfer of fluids. Its design allows for easy installation and removal, which is particularly beneficial during maintenance or repairs. The clamp ensures a tight seal, preventing leaks that could lead to system inefficiencies or safety hazards.

Fuel Drain Systems

When integrated into fuel drain systems, the 4357773 Tube Clamp plays a significant role in maintaining the integrity of the fuel lines. It secures the connections between the fuel tank and the drain lines, ensuring that fuel is efficiently and safely routed away from the system. This is important for both operational efficiency and safety, as any loose connections could result in fuel spills or improper drainage.

Turbocharger Systems

In turbocharger applications, the 4357773 Tube Clamp is used to connect the turbocharger to the intake and exhaust systems. This ensures that the airflow through the turbocharger is maintained at optimal levels, enhancing the engine’s performance. The clamp’s ability to withstand high temperatures and pressures makes it suitable for this demanding application, contributing to the overall reliability and efficiency of the turbocharger system.

Conclusion

The Cummins 4357773 Tube Clamp is a vital component in commercial truck systems, offering durability, ease of installation, and reliable performance in harsh conditions. Its compatibility with various Cummins engines ensures that it can be used across different applications, from plumbing systems to turbocharger systems. Regular maintenance and adherence to safety guidelines are essential to maximize the benefits of this part, ensuring the longevity and efficiency of the truck’s systems.

-

Stiesch, Gunnar. Modeling Engine Spray and Combustion Processes. Springer Verlag, 2003.

↩ -

Sheng, Gang. Vehicle Noise, Vibration and Sound Quality. SAE International, 2012.

↩ -

Miedema, S. A., and Z. Lu. The Dynamic Behavior of a Diesel Engine. Published by Drir S. A. Miedema, 2010.

↩ -

Martyr, A.J. Engine Testing: Theory and Practice: Third Edition. SAE International, 2007.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.