This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

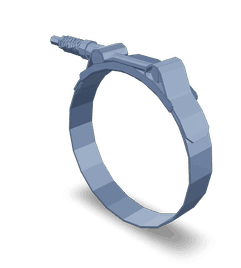

The T-Bolt Clamp 4362171, manufactured by Cummins, is a component designed for use in commercial truck applications. Cummins, a well-established name in the automotive industry, produces this clamp to meet the demanding requirements of heavy-duty truck operations. This Cummins part is significant in maintaining the integrity and efficiency of various truck systems.

Basic Concepts of T-Bolt Clamps

A T-Bolt Clamp is a type of fastener used to secure components in mechanical systems. It operates by clamping two surfaces together, providing a secure connection that can withstand significant stress and vibration. The T-Bolt design allows for easy installation and removal, making it a popular choice in applications where frequent adjustments or replacements are necessary 1.

Purpose of the 4362171 T-Bolt Clamp in Truck Operations

This part plays a specific role in the operation and maintenance of commercial trucks. It is utilized in areas where secure and reliable connections are required, such as in exhaust systems, fuel lines, and other critical components. The clamp ensures that these connections remain intact under the harsh conditions encountered in truck operations, contributing to the overall system integrity and performance 2.

Key Features of the 4362171 T-Bolt Clamp

The 4362171 T-Bolt Clamp is characterized by several design elements and material properties that enhance its effectiveness. Its construction includes high-quality materials that offer durability and resistance to corrosion. The clamp is designed for ease of installation, featuring a T-Bolt mechanism that allows for quick and secure fastening. These features contribute to its reliability in demanding truck applications 3.

Benefits of Using the 4362171 T-Bolt Clamp

Utilizing this Cummins part provides several advantages. It offers enhanced security of connections, ensuring that components remain firmly in place even under vibration and stress. The clamp’s resistance to corrosion extends its service life, reducing the need for frequent replacements. Additionally, its design promotes long-term reliability, contributing to the efficient operation of truck systems.

Installation and Usage Guidelines

Proper installation of the 4362171 T-Bolt Clamp involves several steps to ensure optimal performance. Begin by cleaning the surfaces where the clamp will be applied to remove any dirt or debris. Position the clamp over the components to be secured, ensuring it is aligned correctly. Use the appropriate tools to tighten the T-Bolt, applying even pressure to achieve a secure connection. Follow best practices for torque settings to avoid over-tightening, which could damage the clamp or the components.

Troubleshooting Common Issues

Typical problems that may arise with T-Bolt Clamps include loosening due to vibration or corrosion over time. To address these issues, regularly inspect the clamps for signs of wear or damage. If a clamp appears loose, re-tighten it according to the manufacturer’s guidelines. In cases of corrosion, consider replacing the clamp to maintain system integrity. Proper maintenance practices can help prevent these issues and ensure the continued reliability of the clamp.

Maintenance Tips for Longevity

To prolong the service life of the 4362171 T-Bolt Clamp, regular inspection and maintenance are recommended. Check the clamp periodically for signs of wear, corrosion, or loosening. Clean the clamp and surrounding areas to remove any buildup that could affect its performance. Applying a corrosion-resistant coating can further protect the clamp from environmental factors. Following these maintenance tips will help maintain the efficiency and reliability of the clamp over time.

Cummins: Manufacturer Overview

Cummins is a reputable manufacturer with a long history in the automotive industry. Known for its commitment to quality and innovation, Cummins produces a wide range of automotive components, including the 4362171 T-Bolt Clamp. The company’s reputation is built on its dedication to delivering reliable and high-performance products that meet the needs of commercial truck operators. Cummins continues to invest in research and development to enhance its product offerings and maintain its position as a leader in the industry.

Cummins Engine Compatibility with Part 4362171

This part is a critical component in the assembly and maintenance of several Cummins engine models. It is designed to secure and stabilize various engine components, ensuring optimal performance and longevity.

QSK19 CM2350 K144G and QSK95 CM2350 K113

In the QSK19 CM2350 K144G and QSK95 CM2350 K113 engines, the T-Bolt Clamp is used to secure the cylinder head to the engine block. This ensures that the cylinder head remains firmly in place, preventing any movement that could lead to leaks or other mechanical failures. The clamp’s design allows for precise adjustment, ensuring that the cylinder head is properly aligned and torqued to the manufacturer’s specifications.

QSK60 CM850 MCRS

For the QSK60 CM850 MCRS engine, the T-Bolt Clamp is utilized in the assembly of the turbocharger system. It plays a crucial role in securing the turbocharger to the engine’s exhaust manifold, ensuring that the turbocharger operates efficiently and reliably. This part’s robust design withstands the high temperatures and pressures encountered in the engine’s exhaust system, contributing to the engine’s overall performance and durability.

Common Application

Across these engines, the T-Bolt Clamp is a versatile component that provides essential support and stability. Its application in securing critical engine components ensures that the engines operate smoothly and efficiently, reducing the risk of mechanical issues and extending the engine’s service life.

Role of Part 4362171 T-Bolt Clamp in Engine Systems

This part is an essential component in securing and maintaining the integrity of various engine systems. Its application is particularly significant in the following areas:

Aftercooler Systems

In aftercooler systems, the T-Bolt Clamp ensures a secure connection between the aftercooler and the associated piping. This clamp helps maintain a leak-free seal, which is vital for the efficient cooling of compressed air. Proper sealing prevents any loss of pressure and ensures that the aftercooler operates within optimal parameters, contributing to the overall efficiency of the engine system.

Hose Kit Applications

When utilized in hose kits, the T-Bolt Clamp plays a key role in connecting hoses to various engine components. Its design allows for easy installation and removal, which is beneficial during maintenance or replacement procedures. The clamp’s ability to provide a tight and consistent seal is important for the reliable transfer of fluids or gases, reducing the risk of leaks that could lead to system inefficiencies or failures.

Tube Kit Integration

In tube kits, the T-Bolt Clamp is used to join tubes and fittings, ensuring a robust and durable connection. This is particularly important in high-pressure or high-temperature environments where the integrity of the connection is paramount. The clamp’s design accommodates various tube sizes and materials, making it a versatile choice for different engine configurations. Its use in tube kits helps in maintaining the structural integrity of the system, ensuring that fluids or gases are transported efficiently and safely throughout the engine.

Conclusion

The 4362171 T-Bolt Clamp is a vital component in the maintenance and operation of commercial trucks and Cummins engines. Its design and material properties ensure durability, resistance to corrosion, and ease of installation. Regular maintenance and proper installation practices are essential to maximize the clamp’s effectiveness and longevity in demanding truck applications.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.