This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

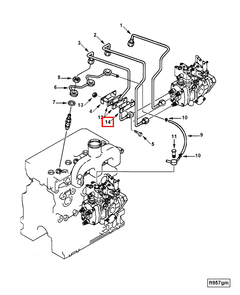

The Cummins 4900751 Tube Clamp is a component designed for use in commercial trucks. It serves to secure and maintain the integrity of tube connections within various truck systems. This clamp ensures that tubes remain firmly in place, which is vital for the proper functioning of the truck’s systems.

Basic Concepts of Tube Clamps

Tube clamps are devices used to hold tubes securely in place. In automotive applications, they play a role in ensuring that fluid or gas lines remain connected without leaks. Tube clamps operate by applying pressure around the tube, creating a seal that prevents disconnection and maintains system integrity 1.

Purpose of the 4900751 Tube Clamp

This Cummins part is specifically designed to secure tubes in commercial truck applications. It is used in various truck systems, including fuel lines, brake systems, and hydraulic lines. By providing a secure connection, it helps maintain the efficiency and safety of these systems.

Key Features

This part features a design that includes a band and a screw mechanism to apply pressure around the tube. It is constructed from durable materials that resist corrosion and wear, ensuring long-term performance. The clamp’s design allows for easy adjustment and secure fitting around tubes of varying diameters.

Benefits

The 4900751 Tube Clamp offers several benefits. It enhances the reliability of tube connections, reducing the risk of leaks and disconnections. Its design allows for straightforward installation, minimizing downtime during maintenance. Additionally, the clamp’s materials and construction contribute to low maintenance requirements 2.

Installation Process

To install the 4900751 Tube Clamp, first, ensure the tube is clean and free of debris. Place the clamp around the tube and use the provided screw to tighten it until the desired pressure is achieved. Tools required may include a wrench for tightening. Follow best practices by checking the connection for leaks after installation.

Troubleshooting Common Issues

Common issues with tube clamps may include leaks or loose connections. These can often be traced to improper installation or wear over time. Troubleshooting steps involve inspecting the clamp for signs of damage, ensuring it is tightened correctly, and replacing it if necessary.

Maintenance Tips

Regular maintenance of the 4900751 Tube Clamp involves periodic inspection for signs of wear or corrosion. Cleaning the clamp and the surrounding area can prevent buildup that may affect performance. Following manufacturer guidelines for inspection intervals ensures the clamp remains in optimal condition.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is known for its innovative solutions and commitment to quality in the commercial truck industry. The company’s product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicles.

Tube Clamp 4900751 Compatibility with Cummins Engines

The Tube Clamp part number 4900751, manufactured by Cummins, is a component in ensuring the integrity and functionality of the engine’s cooling system. This part is designed to securely hold and seal tubes, preventing leaks and maintaining the system’s efficiency.

A1400 Engine

In the A1400 engine, the Tube Clamp 4900751 is used to secure coolant tubes that are integral to the engine’s cooling system. Proper installation and maintenance of this clamp are important to prevent coolant leaks, which can lead to overheating and potential engine damage.

A1700 Engine

Similarly, in the A1700 engine, the Tube Clamp 4900751 plays a role in maintaining the structural integrity of the coolant tubes. This clamp ensures that the tubes remain firmly in place, allowing for efficient coolant flow and temperature regulation.

Grouping of Engines

Both the A1400 and A1700 engines benefit from the use of the Tube Clamp 4900751, as it is a common component in their cooling systems. The clamp’s design and material ensure that it can withstand the operational stresses and temperatures within these engines, providing a reliable seal and support for the coolant tubes.

By using the Tube Clamp 4900751, these engines can maintain optimal performance and longevity, as the clamp helps to prevent leaks and maintain the integrity of the cooling system.

Role of Part 4900751 Tube Clamp in Plumbing and Fuel Systems

The Tube Clamp, identified by part number 4900751, is a component in both plumbing and fuel systems, ensuring secure and reliable connections between various tubes and pipes.

Plumbing Systems

In plumbing systems, the Tube Clamp is utilized to join sections of tubing, particularly in applications where flexibility and ease of installation are required. It provides a robust seal that prevents leaks, which is vital for maintaining the integrity of the plumbing network. The clamp is often used in conjunction with fittings such as elbows, tees, and reducers to create complex piping layouts. Its ability to accommodate slight misalignments between tubing sections makes it ideal for both residential and commercial plumbing installations.

Fuel Systems

Within fuel systems, the Tube Clamp plays a role in securing fuel lines, ensuring that the fuel delivery remains consistent and leak-free. This is particularly important in automotive and aerospace applications where fuel lines are subjected to vibrations and varying pressures. The clamp helps maintain a tight seal around the fuel tubing, preventing any potential fuel leaks that could pose safety hazards. It is commonly used in conjunction with fuel injectors, fuel rails, and fuel filters to ensure that the fuel system operates efficiently and reliably.

In both plumbing and fuel systems, the Tube Clamp contributes to the overall stability and performance of the system by providing a dependable connection method that can withstand the stresses and environmental conditions these systems often encounter.

Conclusion

The Cummins 4900751 Tube Clamp is a vital component in commercial trucks, ensuring the integrity and functionality of various systems including fuel lines, brake systems, and hydraulic lines. Its robust design, ease of installation, and low maintenance requirements make it an essential part for maintaining the efficiency and safety of truck operations. Regular maintenance and proper installation are key to maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.