4917414

Tube Clamp

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

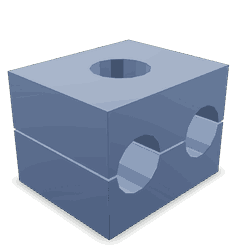

The Tube Clamp 4917414, manufactured by Cummins, is a component designed for use in commercial truck operations. Cummins, a well-established name in the industry, produces a range of parts and systems that contribute to the efficiency and reliability of heavy-duty vehicles. This part is significant in maintaining the integrity of various tubing systems within these trucks.

Basic Concepts of Tube Clamps

Tube clamps are devices used to secure and connect tubing systems in both automotive and industrial applications. They function by providing a tight seal around the tubing, ensuring that fluids or gases are transported efficiently without leaks. Tube clamps are preferred in many applications due to their ease of installation, adjustability, and the secure connection they provide 1.

Purpose of the 4917414 Tube Clamp in Truck Operations

This Cummins part is utilized in commercial trucks to secure and connect various tubing systems. It plays a role in ensuring that the connections within these systems remain intact under the demanding conditions trucks often face. This clamp is applied in systems where reliable and durable connections are necessary to maintain the performance and safety of the vehicle.

Key Features of the 4917414 Tube Clamp

This part is engineered with specific design and construction features to enhance its performance and durability. It is constructed from materials that offer resistance to corrosion and wear, ensuring longevity in harsh environments. The clamping mechanism is designed to provide a secure fit around the tubing, accommodating various diameters and ensuring a leak-free connection. Unique attributes of this clamp may include an ergonomic design for ease of use and a robust construction that withstands vibrations and temperature fluctuations.

Benefits of Using the 4917414 Tube Clamp

Utilizing this part offers several advantages. It contributes to improved safety by ensuring secure connections in critical systems. The reliability of the clamp reduces the likelihood of leaks, which can be hazardous in systems carrying fluids or gases. Its design allows for ease of installation, minimizing downtime during maintenance. Additionally, the clamp’s durability and resistance to environmental factors contribute to maintenance efficiency, as it requires less frequent replacement or adjustment.

Installation Process

Installing the 4917414 Tube Clamp involves several steps to ensure a secure fit. The process begins with selecting the appropriate clamp size for the tubing diameter. Tools required may include a wrench for tightening the clamp and possibly a torque wrench to ensure the correct tension is applied. Preparation steps involve cleaning the tubing to remove any debris that could affect the seal. The clamp is then positioned around the tubing and tightened according to the manufacturer’s specifications to achieve the desired compression without damaging the tubing.

Maintenance and Troubleshooting

Regular maintenance of the 4917414 Tube Clamp is important to ensure its longevity and optimal performance. This includes periodic checks for signs of wear or corrosion and ensuring that the clamp remains securely tightened. Common issues that may arise include leaks, which can often be addressed by re-tightening the clamp or, if necessary, replacing it. Troubleshooting tips involve inspecting the clamp and tubing for damage and ensuring that the clamp is the correct size and type for the application.

Compatibility and Applications

The 4917414 Tube Clamp is designed to be compatible with a range of tubing types and is commonly used in specific applications within commercial trucks. Its versatility allows it to be applied in various systems where secure and durable connections are required.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, related technologies, and complete power systems. With a history of innovation and a strong reputation in the commercial truck industry, Cummins is known for producing high-quality parts and systems that enhance the performance, efficiency, and reliability of heavy-duty vehicles.

Tube Clamp 4917414 Compatibility with Cummins Engines

This Cummins part is a crucial component designed to secure and stabilize various tubes and pipes within the engine system. It is compatible with a range of Cummins engines, ensuring a secure fit and reliable performance. Below is a detailed description of its compatibility with specific engine models:

QSK38 Series

- QSK38 CM2150 MCRS

- QSK38 CM850 MCRS

This part is engineered to fit seamlessly within the QSK38 series engines, specifically the CM2150 and CM850 models. Its robust design ensures that it can handle the unique demands of these engines, providing essential support and stability to the tubes and pipes.

QSK50 Series

- QSK50 CM2150 K107

- QSK50 CM2150 MCRS

- QSK50 CM2350 K108

In the QSK50 series, this part is compatible with both the CM2150 and CM2350 models. It is designed to fit the specific configurations of these engines, ensuring that it can effectively secure and stabilize the necessary components. Whether used in the K107 or MCRS models, the clamp provides reliable performance.

QSK60 Series

- QSK60 CM850 MCRS

For the QSK60 series, this part is specifically designed to fit the CM850 model. Its precision engineering ensures that it can meet the demands of this engine, providing the necessary support and stability to the tubes and pipes.

QSK95 Series

- QSK95 CM2350 K111

- QSK95 CM2350 K113

This part is also compatible with the QSK95 series, specifically the CM2350 models. It is designed to fit the unique requirements of these engines, ensuring that it can effectively secure and stabilize the necessary components. Whether used in the K111 or K113 models, the clamp provides reliable performance.

By ensuring compatibility with these various engine models, this part plays a vital role in maintaining the integrity and performance of the engine systems.

Role of Part 4917414 Tube Clamp in Engine Systems

This part is an essential component in ensuring the secure and efficient operation of various engine systems. Its primary function is to maintain the integrity of the connections within the fuel supply plumbing, fuel drain plumbing, and turbocharger oil plumbing.

In the fuel supply plumbing, the Tube Clamp ensures that the fuel lines are securely fastened to the fuel injectors and other components. This secure connection prevents fuel leaks, which can be hazardous, and ensures that the fuel is delivered consistently to the engine, supporting optimal performance.

For the fuel drain plumbing, the Tube Clamp plays a significant role in maintaining a leak-free system. Proper drainage of excess fuel is necessary to prevent contamination and ensure that the fuel system operates efficiently. The clamp helps in keeping the drain lines intact, thereby avoiding any potential fuel spills or system malfunctions.

In the turbocharger oil plumbing, the Tube Clamp is used to secure the oil lines that supply lubrication to the turbocharger. This is vital for the turbocharger’s longevity and performance, as consistent oil flow prevents overheating and wear on the turbocharger components.

Additionally, the Tube Clamp is utilized in various other engine systems, such as the connections to the cylinder head and around the camshaft and gear assembly. Secure plumbing connections around these areas are important for maintaining the engine’s overall performance and reliability.

Conclusion

In summary, the 4917414 Tube Clamp is a fundamental component in maintaining the structural and functional integrity of the engine’s plumbing systems, directly influencing the engine’s performance and safety. Its compatibility with various Cummins engine models ensures that it can meet the demands of different applications, providing reliable and durable connections in critical systems.

-

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.