This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

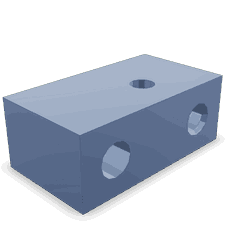

The Cummins 4934269 Clamping Bracket is a component designed to secure various parts within the mechanical systems of commercial trucks. Its role is significant in maintaining the structural integrity and operational efficiency of these vehicles. By ensuring that components remain firmly in place, the clamping bracket contributes to the overall reliability and performance of the truck 1.

Basic Concepts of Clamping Brackets

A clamping bracket is a mechanical device used to hold two or more objects together. It operates by applying pressure to the objects it secures, typically through a screw, bolt, or other tightening mechanism. This pressure ensures that the components remain in the correct position and orientation, preventing movement that could lead to malfunction or failure. Clamping brackets are integral to many mechanical systems, providing stability and security to various assemblies 2.

Purpose of the 4934269 Clamping Bracket

The Cummins 4934269 Clamping Bracket is specifically designed to secure particular components or assemblies within a truck’s mechanical system. Its application ensures that these components remain stable under various operating conditions, contributing to the truck’s overall performance and reliability. By maintaining the correct positioning of parts, the clamping bracket plays a role in the efficient operation of the vehicle 3.

Key Features

The Cummins 4934269 Clamping Bracket features a robust material composition, typically including high-strength steel or other durable alloys. Its design incorporates elements such as precision-machined surfaces and reinforced edges to enhance its functionality. These features contribute to the bracket’s ability to withstand significant stress and maintain a secure hold on the components it supports 4.

Benefits

The Cummins 4934269 Clamping Bracket offers several benefits, including improved stability, durability, and efficiency in truck operations. By securely holding components in place, it reduces the risk of misalignment or movement that could lead to mechanical issues. Its durable construction ensures long-term reliability, while its efficient design contributes to the overall performance of the truck 5.

Installation Process

Proper installation of the Cummins 4934269 Clamping Bracket involves several steps. Begin by identifying the correct location for the bracket on the truck’s mechanical system. Use the appropriate tools to loosen any existing fasteners and remove the old bracket, if applicable. Position the new bracket in place and secure it using the provided fasteners, ensuring that all components are tightly and correctly aligned. Finally, perform a thorough inspection to confirm that the bracket is properly installed and that all secured components are stable 6.

Troubleshooting Common Issues

Common problems associated with the Cummins 4934269 Clamping Bracket may include loosening of the fasteners, corrosion, or damage to the bracket itself. To address these issues, first, inspect the bracket and fasteners for signs of wear or corrosion. Tighten any loose fasteners and clean or replace corroded components as necessary. If the bracket is damaged, it may need to be replaced to ensure the continued stability and reliability of the secured components 7.

Maintenance Tips

Regular maintenance of the Cummins 4934269 Clamping Bracket is important to ensure its longevity and optimal performance. Inspect the bracket and fasteners at regular intervals, checking for signs of wear, corrosion, or damage. Clean the bracket as needed to remove any dirt or debris that could affect its performance. Lubricate the fasteners to prevent seizing and ensure smooth operation. Following these maintenance tips will help to maintain the bracket’s effectiveness and contribute to the overall reliability of the truck 8.

Cummins Engine Compatibility with Part 4934269

The Cummins Clamping Bracket part number 4934269 is designed to fit seamlessly with several engine models, ensuring compatibility and reliability across different applications. This part is integral to the engine’s structure, providing necessary support and stability.

QSB6.7 CM2250 and QSB6.7 CM850 (CM2850)

The Clamping Bracket part 4934269 is compatible with the QSB6.7 CM2250 and QSB6.7 CM850 (CM2850) engines. These engines are known for their robust performance and efficiency, making them suitable for a variety of applications, from agricultural to industrial use. The bracket’s design ensures it fits perfectly with these engines, providing the necessary support for various components and ensuring smooth operation 9.

QSB7 CM2880 B117

Similarly, the QSB7 CM2880 B117 engine also benefits from the use of the Clamping Bracket part 4934269. This engine is part of the Cummins QSB series, which is designed for high-performance applications. The bracket’s compatibility with this engine ensures that it can handle the demands of heavy-duty operations, providing the necessary support and stability to maintain engine integrity and performance 10.

Role of Part 4934269 Clamping Bracket in Engine Systems

The 4934269 Clamping Bracket is a component in securing various engine system elements, ensuring their proper function and integration within the engine assembly.

In the arrangement of engine components, the Clamping Bracket plays a role by providing a stable mounting point for multiple parts. It ensures that components are held firmly in place, reducing the risk of movement or misalignment during engine operation.

For the oil fill system, the Clamping Bracket is used to secure the oil fill tube and associated plumbing. This ensures a leak-free connection, maintaining the integrity of the oil supply to the engine. Proper clamping prevents oil leaks, which could lead to decreased lubrication and potential engine damage.

In the fuel supply system, the Clamping Bracket is instrumental in holding the fuel supply tube and related plumbing in position. This secure attachment is vital for maintaining a consistent fuel flow to the engine, ensuring optimal performance and efficiency. The bracket helps to prevent fuel line disconnections or leaks, which could pose safety hazards and affect engine operation.

Overall, the 4934269 Clamping Bracket contributes to the reliability and efficiency of engine systems by providing a robust and secure connection point for various components. Its role in maintaining the structural integrity and functional alignment of these parts is fundamental to the overall performance of the engine 11.

Conclusion

The Cummins 4934269 Clamping Bracket is a vital component in the mechanical systems of commercial trucks, ensuring the stability and efficiency of various engine components. Its robust design, compatibility with multiple engine models, and essential role in maintaining the integrity of engine systems make it a critical part for truck operations. Regular maintenance and proper installation are key to maximizing the performance and longevity of this Cummins part.

-

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Majewski, Addy, and Hannu Jaskelainen. Diesel Emissions and Their Control: Second Edition. SAE International, 2023.

↩ -

Smil, Vaclav. The History and Impact of Diesel Engines and Gas Turbines. The MIT Press, 2010.

↩ -

Arora, Shashank, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi. Heavyduty Electric Vehicles: From Concept to Reality. Elsevier, 2021.

↩ -

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Majewski, Addy, and Hannu Jaskelainen. Diesel Emissions and Their Control: Second Edition. SAE International, 2023.

↩ -

Smil, Vaclav. The History and Impact of Diesel Engines and Gas Turbines. The MIT Press, 2010.

↩ -

Arora, Shashank, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi. Heavyduty Electric Vehicles: From Concept to Reality. Elsevier, 2021.

↩ -

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Majewski, Addy, and Hannu Jaskelainen. Diesel Emissions and Their Control: Second Edition. SAE International, 2023.

↩ -

Smil, Vaclav. The History and Impact of Diesel Engines and Gas Turbines. The MIT Press, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.