This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

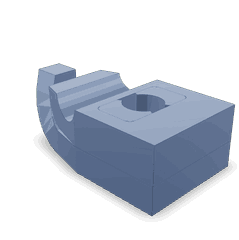

The 4934270 Tube Clamp, manufactured by Cummins, is a component designed for use in commercial trucks. This part secures and connects various tubes within the vehicle’s systems, playing a role in the engine cooling, fuel, exhaust, and coolant systems 2. Tube clamps are essential in the automotive industry for their ability to join tubes without welding or soldering, offering a convenient and efficient solution 3.

Basic Concepts of Tube Clamps

Tube clamps are devices that secure and connect tubes by compressing them between two surfaces, creating a seal for the transfer of fluids or gases 4. This method is favored in automotive applications for its simplicity, efficiency, and the secure, leak-proof joints it provides without requiring additional materials or processes 1.

Purpose of the 4934270 Tube Clamp in Truck Operations

In commercial trucks, the 4934270 Tube Clamp is used in fuel, exhaust, and coolant systems to secure connections between tubes. This ensures the efficient and safe transfer of fluids and gases, contributing to the truck’s performance and reliability 2.

Key Features of the 4934270 Tube Clamp

This Cummins part is constructed from high-quality materials that resist corrosion and wear, ensuring durability in demanding environments 3. Its clamping mechanism provides a secure fit, minimizing the risk of leaks or disconnections. The clamp’s design also allows for easy installation and adjustment, making it practical for maintenance and repair tasks 4.

Benefits of Using the 4934270 Tube Clamp

The 4934270 Tube Clamp offers easy installation, reducing downtime during maintenance or repair tasks. It provides a reliable connection, ensuring tubes remain securely joined under various operating conditions. Its resistance to environmental factors enhances its durability and performance over time 1.

Installation Process

Installing the 4934270 Tube Clamp involves cleaning and inspecting the tubes, positioning the clamp over the tubes, and tightening it evenly to ensure a secure fit 2. Care should be taken to avoid damaging the tubes or creating an uneven seal.

Troubleshooting Common Issues

Common issues with tube clamps, such as leaks or loose connections, can often be traced back to improper installation or wear and tear. Inspecting the clamp and connection for damage or misalignment can help address these problems. If a leak is detected, the clamp may need to be retightened or replaced 3.

Maintenance Tips

Regular maintenance of the 4934270 Tube Clamp is important for its continued performance and reliability. This includes periodic inspection for wear, corrosion, or damage, and cleaning the clamp and surrounding areas to prevent dirt or debris buildup 4.

Cummins: A Brief Overview

Cummins Inc. is a global leader in designing, manufacturing, and distributing engines, filtration, and power generation products. With a history spanning over a century, Cummins is known for its quality, innovation, and reliability in the commercial vehicle industry 1.

Compatibility with Cummins Engines

The Tube Clamp 4934270 is designed to fit seamlessly with several Cummins engine models, including the QSB6.7 CM850 (CM2850), QSB7 CM2880 B117, and QST30 CM2350 T101. It is used to secure tubes and hoses critical for the engine’s cooling and fuel systems, ensuring optimal performance and longevity 2.

Role of the 4934270 Tube Clamp in Engine Systems

The 4934270 Tube Clamp plays a significant role in the engine system by ensuring the integrity and efficiency of the fuel delivery and drainage processes. It secures connections between various fuel system components, facilitating a seamless flow of fuel throughout the system 3.

Fuel Supply Tube

This part is employed to fasten the fuel supply tube to the fuel pump, maintaining consistent fuel pressure and flow rate, which are vital for the engine’s performance. It prevents potential leaks at the connection point, ensuring the fuel supply remains uncontaminated and efficient 4.

Plumbing Connections

Within engine plumbing, the Tube Clamp is utilized at various junctures where fuel lines intersect or connect to other components. Its application provides a tight seal that withstands the pressures and vibrations inherent in engine operation, ensuring the longevity and efficiency of the fuel system 1.

Fuel Drain

At the fuel drain, the 4934270 Tube Clamp secures the drain tube to the fuel tank, ensuring a controlled and leak-free drain process. This contributes to the overall safety and maintenance of the engine system 2.

Fuel Supply and Pump

The interface between the fuel supply line and the fuel pump is another area where the Tube Clamp is critical. By ensuring a secure and leak-proof connection, it allows the fuel pump to operate efficiently, delivering fuel to the engine under the required pressure 3.

Conclusion

The 4934270 Tube Clamp is integral to the fuel system’s architecture, providing the necessary connections for the efficient and safe operation of the engine. Its role in securing various fuel system components underscores the importance of reliable connections in engine mechanics 4.

-

Sheng, Gang. Vehicle Noise, Vibration and Sound Quality. SAE International, 2012.

↩ ↩ ↩ ↩ -

Hilgers, Michael. The Diesel Engine Second Edition. Springer Nature, 2023.

↩ ↩ ↩ ↩ ↩ -

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill, 2018.

↩ ↩ ↩ ↩ ↩ -

Sander, Frank. Diesel Mechanics, First Edition. Global Media, 2007.

↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.