This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

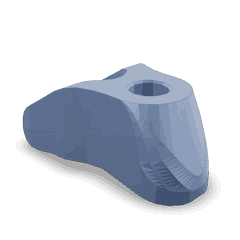

The Cummins Injector Clamp, part number 4944917, is a component designed for use in heavy-duty truck engines. Cummins, a well-established name in the automotive industry, is known for producing reliable and high-performance engine parts. This Cummins part is significant in the context of heavy-duty truck engines due to its role in ensuring the secure and efficient operation of fuel injectors.

Purpose and Function

The Injector Clamp 4944917 plays a role in the operation of a truck engine by securing the fuel injector in place. This ensures that the injector remains stable during engine operation, which is vital for maintaining the integrity of the fuel delivery system. Proper fuel delivery is essential for engine performance, and the clamp contributes to this by preventing the injector from moving or vibrating excessively, which could lead to fuel leaks or inefficient fuel delivery 1.

Key Features

The Injector Clamp 4944917 is designed with several features that enhance its performance and durability. It is constructed from high-quality materials that can withstand the harsh conditions within a heavy-duty truck engine. The clamping mechanism is engineered to provide a secure hold on the fuel injector, ensuring that it remains in the correct position. Additionally, the clamp may include unique attributes such as corrosion-resistant coatings or specialized designs that improve its functionality in demanding environments 2.

Benefits

The use of the Injector Clamp 4944917 offers several advantages. It contributes to improved fuel efficiency by ensuring that the fuel injector operates within the designed parameters. Enhanced engine performance is another benefit, as the secure placement of the injector allows for precise fuel delivery. Furthermore, the clamp reduces the risk of fuel leaks or injector malfunctions, which can lead to engine damage or decreased performance 3.

Installation and Maintenance

Proper installation of the Injector Clamp 4944917 is important for its effective operation. Installation guidelines may include torque specifications to ensure that the clamp is tightened to the correct level without over-tightening, which could damage the injector or the clamp itself. Alignment procedures should be followed to ensure that the injector is positioned correctly within the engine. Maintenance tips for the clamp include regular inspection for signs of wear or damage and ensuring that it remains clean and free from debris that could affect its performance 4.

Troubleshooting Common Issues

Common problems associated with injector clamps may include leaks or improper clamping. Troubleshooting steps for these issues may involve checking the clamp for damage, ensuring that it is installed correctly, and verifying that the torque specifications were followed during installation. Solutions may include replacing a damaged clamp, re-torquing the clamp to the correct specifications, or cleaning the clamp and injector to remove any debris that could be causing issues.

Compatibility and Applications

The Injector Clamp 4944917 is compatible with various Cummins engine models and is used in different types of heavy-duty trucks. Its applications are diverse, ranging from long-haul trucking to construction and mining equipment, where reliable fuel injection is crucial for performance and efficiency.

Safety Considerations

When working with injector clamps, it is important to follow safety precautions and best practices. This includes proper handling to avoid injury, storing the clamps in a dry and secure location to prevent damage, and disposing of them in accordance with local regulations to minimize environmental impact. These practices help to ensure the safety of personnel and the longevity of the equipment.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a full line of power generation and related technologies. With a history spanning over a century, Cummins is recognized for its commitment to quality and innovation in the automotive industry. The company offers a wide range of products, including engines, filtration, emissions solutions, and power systems, serving customers in more than 190 countries and territories. Cummins’ reputation for reliability and performance makes it a preferred choice for heavy-duty applications, including the Injector Clamp 4944917.

Cummins Injector Clamp 4944917 Compatibility

The Cummins Injector Clamp part number 4944917 is designed to fit a variety of Cummins engine models. This clamp is essential for securing the injectors in place, ensuring proper operation and longevity of the engine components. Below is a detailed breakdown of the engine models compatible with this injector clamp:

B4.5 CM2350 Series

- B4.5 CM2350 B129B

- ISB4.5 CM2350 B104

D4.0 CM2620 Series

- D4.0 CM2620 D103B

F3.8 CM2350 Series

- F3.8 CM2350 F120B

- F3.8 CM2350 F128C

- QSF3.8 CM2350 F107

F3.8 CM2620 Series

- F3.8 CM2620 F137B

F4.5 Series

- F4.5 CM2620 F139B

- F4.5 CM2620 F141C

- F4.5 CM2620 F137B

ISF3.8 CM2220 Series

- ISF3.8 CM2220 AN

- ISF3.8 CM2220 F103

- ISF3.8 CM2350 F109

ISF4.5 CM2220 Series

- ISF4.5 CM2220 F123

QSF3.8 CM2880 Series

- QSF3.8 CM2880 F112

This compatibility list ensures that the injector clamp can be used across a range of Cummins engines, providing a reliable solution for securing injectors in various engine configurations.

Role of Part 4944917 Injector Clamp in Engine Systems

The Injector Clamp, identified by part number 4944917, plays a significant role in ensuring the efficient operation of various engine components. It is specifically designed to secure the injector within the cylinder head, maintaining a stable and precise fuel delivery system.

When the injector is properly clamped, it ensures that fuel is delivered consistently and accurately into the combustion chamber. This is essential for optimal engine performance, as it directly influences the air-fuel mixture. A stable mixture is vital for efficient combustion, which in turn affects the engine’s power output and fuel efficiency.

The Injector Clamp also interacts with the injector plumbing, ensuring that there are no leaks in the fuel delivery system. This is important for maintaining the integrity of the fuel pressure and preventing any fuel from escaping, which could lead to inefficient engine operation or even safety hazards.

Furthermore, the clamp’s role extends to supporting the overall structural integrity of the cylinder head. By securely holding the injector in place, it helps to prevent any undue stress on the head and cylinder, which could otherwise lead to warping or other forms of damage. This is particularly important in high-performance engines where the components are subjected to greater stresses and temperatures.

In summary, the Injector Clamp (part 4944917) is an integral component in the engine system, contributing to the stability and efficiency of fuel delivery, the integrity of the injector plumbing, and the structural soundness of the cylinder head and cylinder. Its proper function is essential for the overall performance and reliability of the engine.

Conclusion

The Cummins Injector Clamp 4944917 is a critical component in the operation of heavy-duty truck engines. Its role in securing the fuel injector ensures the stability and efficiency of the fuel delivery system, contributing to optimal engine performance and reliability. Proper installation, maintenance, and understanding of its compatibility with various Cummins engine models are essential for maximizing the benefits of this part.

-

Duffy, Owen C, and Gus Wright. Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning, 2016.

↩ -

Boyce, Meherwan P. Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing, 2002.

↩ -

Carroll, Douglas R. Energy Efficiency of Vehicles. SAE International, 2020.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 5504359, 2021.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.