4990085

Tube Clamp

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4990085 Tube Clamp is a specialized component designed for use in commercial trucks. Its primary function is to secure tubing within the vehicle’s systems, ensuring that connections remain tight and secure under various operating conditions. This clamp is integral to maintaining the integrity of fluid and air systems in trucks, contributing to the overall reliability and performance of the vehicle.

Basic Concepts of Tube Clamps

Tube clamps are mechanical devices used to hold tubing in place. They are commonly employed in automotive and industrial applications to secure hoses and pipes, ensuring that connections are tight and leak-free. Tube clamps function by applying pressure around the tubing, creating a secure seal that prevents fluid or air from escaping. This is achieved through a band that wraps around the tube and is tightened using a screw or band mechanism 1.

Purpose of the 4990085 Tube Clamp in Truck Operation

The 4990085 Tube Clamp plays a role in the operation of a commercial truck by securing various types of tubing used in the vehicle’s systems. This includes fuel lines, brake lines, and air systems. By maintaining a secure connection, the clamp helps prevent leaks and ensures that systems operate efficiently. Its application is vital in environments where vibrations and harsh conditions could otherwise loosen connections, potentially leading to system failures 2.

Key Features

The Cummins 4990085 Tube Clamp is constructed from high-quality materials, ensuring durability and resistance to corrosion. Its design includes a robust band that provides a strong grip on the tubing, and it features an easy-to-use tightening mechanism that allows for quick and secure installation. Additionally, the clamp is designed to accommodate a range of tubing sizes, making it versatile for various applications within the truck’s systems.

Benefits of Using the 4990085 Tube Clamp

Utilizing the 4990085 Tube Clamp offers several advantages. Its durable construction ensures long-term reliability, reducing the need for frequent replacements. The ease of installation allows for quick maintenance and repair, minimizing downtime. Furthermore, its design ensures a secure fit, which is crucial in maintaining the integrity of the truck’s systems under various operating conditions 3.

Installation Process

Installing the 4990085 Tube Clamp involves several steps to ensure a secure fit. First, the tubing should be cleaned and inspected for any damage. The clamp is then positioned around the tubing and tightened using the provided screw or band mechanism. It is important to ensure that the clamp is tightened evenly to avoid damaging the tubing. Tools required for installation may include a wrench or screwdriver, depending on the specific design of the clamp.

Troubleshooting Common Issues

Common issues with tube clamps may include leaks or loose fittings. To address these problems, first, ensure that the clamp is properly tightened. If leaks persist, inspect the tubing for damage or wear. In some cases, replacing the tubing or the clamp may be necessary to resolve the issue. Regular inspections can help identify potential problems before they lead to system failures.

Maintenance Tips

To ensure the long-term performance and reliability of the 4990085 Tube Clamp, regular maintenance is recommended. This includes periodic inspections to check for signs of wear or corrosion. If the clamp shows signs of damage, it should be replaced to maintain system integrity. Additionally, ensuring that the clamp remains tightened and that the tubing is in good condition will contribute to the overall reliability of the truck’s systems.

Cummins Overview

Cummins Inc. is a leading manufacturer of diesel engines, with a history of innovation and commitment to quality in the automotive industry. The company’s products are designed to meet the demanding requirements of commercial vehicles, providing reliable performance and efficiency. Cummins’ dedication to quality and innovation is evident in their range of components, including the 4990085 Tube Clamp, which is engineered to meet the high standards required for commercial truck applications.

Compatibility with Cummins Engines

The Tube Clamp 4990085 is compatible with a variety of Cummins engines, ensuring a secure fit across diverse engine models. Below is a detailed overview of the engines with which this tube clamp is compatible:

Compatible Engines

- 6B5.9

- B5.6 CM2670 B152B

- C GAS PLUS CM556

- ISB5.9 CM2880 B110

- ISB5.9 CM2880 B140

- ISB5.9 CM2880 B149

- ISC CM2150

- ISC8.3 CM2250

- ISL CM2150

- ISL G CM2180

- ISL9 CM2150 SN

- ISL9 CM2250

- L8.9G CMOH2.0 L125B

- QSC8.3 CM850(CM2850)

- QSC9 CM2250/QSL9 CM2250

- QSL9 CM2250

- QSL9 CM2350 L102

Grouping of Compatible Engines

ISB Series

- ISB5.9 CM2880 B110

- ISB5.9 CM2880 B140

- ISB5.9 CM2880 B149

ISC Series

- ISC CM2150

- ISC8.3 CM2250

ISL Series

- ISL CM2150

- ISL G CM2180

- ISL9 CM2150 SN

- ISL9 CM2250

QSC and QSL Series

- QSC8.3 CM850(CM2850)

- QSC9 CM2250/QSL9 CM2250

- QSL9 CM2250

- QSL9 CM2350 L102

Other Models

- 6B5.9

- B5.6 CM2670 B152B

- C GAS PLUS CM556

- L8.9G CMOH2.0 L125B

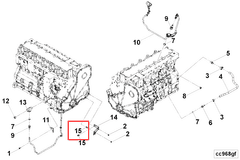

Role of the 4990085 Tube Clamp in Engine Systems

The 4990085 Tube Clamp is an essential component in ensuring the secure and efficient operation of various engine systems. Its primary function is to maintain the integrity of fluid pathways within the engine, particularly in systems involving the compressor coolant and air arrangements.

In the compressor coolant system, the Tube Clamp secures the connections between the compressor coolant tubes and the compressor water outlet tube. This ensures that the coolant flows smoothly without leaks, which is vital for maintaining optimal compressor temperature and efficiency. The clamp’s reliable hold prevents vibrations and movement that could otherwise disrupt the coolant flow, thereby safeguarding the compressor’s performance.

Within the air arrangement system, the Tube Clamp plays a similar role by securing air tubes and braces. This is particularly important in maintaining the correct air-fuel mixture and ensuring that the air pathways remain unobstructed. The clamp helps in reducing the risk of air leaks, which could lead to inefficient combustion and reduced engine performance.

Additionally, the Tube Clamp is used in the electronic control module wiring harness to secure wiring that runs alongside fluid tubes. This not only protects the wiring from physical damage but also ensures that the electrical connections remain stable and reliable, contributing to the overall efficiency of the engine’s electronic systems.

In plumbing applications within the engine, the Tube Clamp is instrumental in joining various tubes and fittings. Its use ensures that all connections are tight and secure, preventing fluid leaks and maintaining the pressure integrity of the system. This is particularly important in high-pressure applications where even a small leak can lead to significant performance issues.

Conclusion

The Cummins 4990085 Tube Clamp is a versatile and reliable component that enhances the functionality and durability of engine systems by ensuring secure and leak-free connections across various fluid and air pathways. Its compatibility with a wide range of Cummins engines, coupled with its robust design and ease of installation, makes it an invaluable part for maintaining the integrity of commercial truck systems.

-

Proceedings of the 5th Commercial Vehicle Technology Symposium CVT, Karsten Berns, Klaus Dressler, Patrick Fleischmann, Daniel Grges, Ralf Kalmar, Bernd Sauer, Nicole Stephan, Roman Teutsch, Martin Thul, Springer, 2018

↩ -

The Repair of Vehicle Bodies, Andrew Livesey, Elevier, 2000

↩ -

The Diesel Engine Second Edition, Michael Hilgers, Springer Nature, 2023

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.