4990321

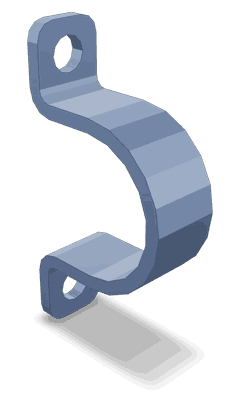

Tube Clamp

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4990321 Tube Clamp is a component designed for use in commercial truck operations. It serves to secure and connect tubing systems within various truck subsystems. Its role is in maintaining the integrity and efficiency of these systems, ensuring that fluids and gases are transported reliably throughout the vehicle.

Basic Concepts of Tube Clamps

Tube clamps are devices used to hold tubing in place and create secure connections in automotive and industrial applications. They function by compressing the tubing against a fixed surface, which creates a seal and prevents leaks. Tube clamps are utilized in a variety of systems where tubing is employed, including fuel lines, hydraulic systems, and exhaust systems 1.

Purpose of the Cummins 4990321 Tube Clamp

This Cummins part is specifically designed to play a role in the secure connection of tubing within a truck’s systems. It is applied in scenarios where reliable and durable connections are required, such as in the fuel delivery system, hydraulic lines, or exhaust components. The clamp ensures that the tubing remains firmly in place, which is important for the proper operation of these systems.

Key Features

The 4990321 is constructed from materials that offer durability and resistance to the elements it may encounter in truck operations. Its design includes elements that enhance its grip on the tubing, ensuring a secure fit. Unique attributes may include corrosion resistance, ease of installation, and compatibility with a range of tubing sizes and types 2.

Benefits of Using the Cummins 4990321 Tube Clamp

Employing this part in truck maintenance and operations offers several advantages. Its durable construction contributes to longevity, reducing the frequency of replacements. The design allows for straightforward installation, which can save time during maintenance procedures. Additionally, its performance under various conditions ensures that it can withstand the rigors of commercial truck use 3.

Installation Process

To install the 4990321, one should first ensure that the tubing is clean and free of any debris that could compromise the seal. The clamp should be positioned over the tubing and tightened using the appropriate tools until the desired compression is achieved. It is important to follow manufacturer guidelines for torque specifications to ensure a proper seal without damaging the tubing.

Common Applications

This part is typically used in various truck systems where secure tubing connections are necessary. Common applications include fuel lines, where it ensures a leak-free connection, hydraulic systems, where it maintains pressure integrity, and exhaust systems, where it helps to secure the tubing against vibrations and movement.

Troubleshooting and Maintenance

Identifying common issues with tube clamps, such as leaks or loose connections, is important for maintaining system integrity. Regular inspection and tightening of the clamps can help ensure their continued effectiveness. If a clamp shows signs of wear or damage, it should be replaced to prevent potential system failures.

Safety Considerations

When working with tube clamps, it is important to follow safety guidelines to prevent accidents or system failures. This includes proper handling of the clamps and tubing, using the correct tools for installation, and adhering to torque specifications. Additionally, safety gear should be worn to protect against any potential hazards during installation or maintenance.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company offers a wide range of products designed to meet the demanding requirements of truck operators and maintainers.

Tube Clamp 4990321 Compatibility with Cummins Engines

The Tube Clamp 4990321, manufactured by Cummins, is a component in ensuring the integrity and functionality of various engine systems. This part is designed to secure and maintain the alignment of tubes and hoses, which are integral to the engine’s operation. Below is a detailed overview of its compatibility across several Cummins engine models.

B6.7 Series

The Tube Clamp 4990321 is compatible with the following B6.7 engines:

- B6.7 CM2350

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

These engines benefit from the clamp’s ability to maintain the structural integrity of the cooling and fuel systems, ensuring optimal performance and longevity.

QSB6.7 Series

The Tube Clamp 4990321 is also suitable for the following QSB6.7 engine:

- QSB6.7 CM2250

In this engine, the clamp plays a role in securing the various tubes and hoses that are part of the engine’s intricate cooling and fuel delivery systems.

G Series

For the G series engines, the Tube Clamp 4990321 is compatible with:

- ISB6.7 G CM2180 B118

This engine model also relies on the clamp to ensure that all tubes and hoses are properly secured, which is important for maintaining the engine’s efficiency and reliability.

By providing a secure fit for these engines, the Tube Clamp 4990321 helps to prevent leaks and maintain the pressure integrity of the systems it is part of, contributing to the overall performance and durability of the engine.

Role of Part 4990321 Tube Clamp in Engine Systems

The 4990321 Tube Clamp is a component in ensuring the secure and efficient operation of various engine systems. Its primary function is to maintain the integrity of connections within these systems, preventing leaks and ensuring optimal performance.

Plumbing Systems

In plumbing systems, the 4990321 Tube Clamp plays a role by securing hoses and pipes that transport fluids such as coolant, oil, and fuel. This ensures that these vital fluids are delivered consistently and without interruption to their respective destinations within the engine. The clamp’s reliable hold prevents any potential leaks that could lead to system failure or reduced efficiency.

Exhaust Recirculation (EGR) Systems

Within Exhaust Recirculation (EGR) systems, the 4990321 Tube Clamp is instrumental in maintaining the seal of hoses that reroute a portion of the exhaust gases back into the intake manifold. This process helps in reducing nitrogen oxides (NOx) emissions, contributing to a cleaner and more environmentally friendly operation. The clamp ensures that the EGR hoses remain firmly in place, allowing for the precise control of exhaust gas flow and preventing any unwanted leaks that could disrupt the EGR system’s functionality.

Air Intake Systems

In air intake systems, the 4990321 Tube Clamp secures the connections between the air filter, intake manifold, and other components responsible for drawing air into the engine. A secure connection is vital for maintaining the correct air-fuel ratio, which is essential for efficient combustion and overall engine performance. The clamp helps in preventing air leaks that could lead to a lean air-fuel mixture, potentially causing engine knocking or decreased power output.

By ensuring secure connections across these systems, the 4990321 Tube Clamp contributes to the reliable and efficient operation of the engine, highlighting its importance in maintaining the overall health and performance of the engine systems.

Conclusion

The Cummins 4990321 Tube Clamp is a vital component in the maintenance and operation of commercial truck systems. Its design and features ensure secure and durable connections in various engine systems, contributing to the overall efficiency and reliability of the vehicle. Regular maintenance and adherence to safety guidelines are essential to maximize the benefits of this part.

-

Quansheng Zhan, Shengbo Eben, Li Kun Deng. Automotive Heating Ventilation and Air Conditioning. Jones Bartlett Learning, 2018.

↩ -

Robert Bosch GmbH. Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg, 2007.

↩ -

Deanna Sclar. Auto Repair for Dummies: 2nd Edition. For Dummies, 2008.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.