This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

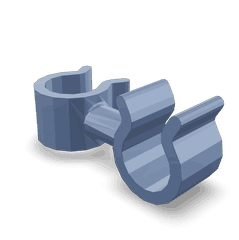

The Cummins 5347636 Tube Clamp is a specialized component designed for use in commercial trucks. Its purpose is to secure tubing systems, ensuring they remain firmly in place under various operational conditions. This clamp is significant in maintaining the integrity and efficiency of truck systems by providing a reliable connection for tubing 2.

Basic Concepts of Tube Clamps

Tube clamps are mechanical fasteners used to secure tubing in automotive and industrial applications. They function by compressing the tubing against a fixed surface, creating a tight seal that prevents leaks and ensures the tubing remains in the desired position. Tube clamps come in various designs and materials, each suited to specific applications based on the type of tubing and the environmental conditions they will encounter 3.

Purpose of the Cummins 5347636 Tube Clamp

The Cummins 5347636 Tube Clamp plays a role in securing tubing within various truck systems. It is applied in fuel lines, hydraulic systems, and other critical areas where secure and leak-free connections are necessary. By providing a stable and reliable hold on the tubing, this clamp helps maintain the efficiency and safety of the truck’s operations 1.

Key Features

The Cummins 5347636 Tube Clamp is constructed from durable materials, ensuring it can withstand the rigors of commercial truck use. Its design includes features such as a robust band and secure fastener mechanism, which contribute to its effectiveness in clamping tubing. Additionally, the clamp may have unique characteristics that enhance its functionality, such as corrosion resistance or ease of adjustment.

Benefits

The Cummins 5347636 Tube Clamp offers several advantages. Its durability ensures long-term performance, reducing the need for frequent replacements. The ease of installation allows for quick setup, minimizing downtime during maintenance. Furthermore, its reliability in securing tubing systems contributes to the overall safety and efficiency of the truck.

Installation Process

Installing the Cummins 5347636 Tube Clamp involves several steps to ensure a secure fit. Begin by positioning the clamp around the tubing and aligning it with the fixed surface. Use the appropriate tools to tighten the clamp, ensuring even pressure is applied across the tubing. Follow best practices, such as checking for proper alignment and ensuring the clamp is not overtightened, to achieve a secure and leak-free connection.

Troubleshooting Common Issues

Common issues with tube clamps may include leaks or improper fitting. To address these problems, first, inspect the clamp and tubing for any signs of damage or misalignment. Ensure the clamp is correctly positioned and tightened to the manufacturer’s specifications. If leaks persist, consider replacing the clamp or inspecting the tubing for defects.

Maintenance Tips

Regular maintenance of the Cummins 5347636 Tube Clamp is important for ensuring long-term performance. Inspect the clamp periodically for signs of wear or corrosion. Clean the clamp and tubing as needed to remove any buildup that could affect the seal. Following these maintenance practices will help maintain the clamp’s effectiveness and reliability.

Safety Considerations

When installing or maintaining the Cummins 5347636 Tube Clamp, it is important to follow safety practices. Wear appropriate personal protective equipment (PPE), such as gloves and safety glasses, to protect against injuries. Handle the clamp and tubing carefully to avoid damage. Additionally, ensure the work area is clean and free of hazards to prevent accidents during the installation process.

Cummins Overview

Cummins Inc. is a leading manufacturer of diesel engines and automotive components, with a history of innovation and commitment to quality. The company’s products are designed to meet the demanding requirements of commercial vehicles, providing reliable performance and efficiency. Cummins’ dedication to excellence is evident in their wide range of components, including the Cummins 5347636 Tube Clamp.

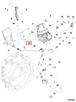

Role of 5347636 Tube Clamp in Engine Systems

The 5347636 Tube Clamp is instrumental in maintaining the integrity and efficiency of various engine systems, particularly in the breather and crankcase components.

Breather System Integration

In the breather system, the Tube Clamp secures the hoses that connect the breather to the engine block and other components. This ensures a tight seal, preventing air leaks that could disrupt the pressure balance within the engine. Proper sealing is essential for the breather system to effectively ventilate the crankcase, removing contaminants and moisture that could otherwise lead to engine wear 2.

Crankcase Ventilation

The crankcase ventilation system relies on the Tube Clamp to maintain a secure connection between the crankcase and the breather or PCV (Positive Crankcase Ventilation) valve. This connection is vital for the system to function correctly, allowing the safe release of gases produced during combustion. The Tube Clamp ensures that these gases are directed back into the intake system rather than escaping into the atmosphere, contributing to reduced emissions and improved engine performance 3.

Enhanced System Reliability

By ensuring a secure fit of hoses and connections, the Tube Clamp plays a significant role in the overall reliability of the engine’s ventilation systems. It helps prevent issues such as oil leaks, reduced engine efficiency, and increased emissions, all of which can arise from loose or disconnected hoses.

Conclusion

In summary, the Cummins 5347636 Tube Clamp is a key component in the effective operation of the breather and crankcase ventilation systems, contributing to the engine’s performance, durability, and environmental compliance. Its role in securing tubing systems ensures the efficiency and safety of truck operations, making it an essential part of commercial truck maintenance and operation.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.