This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

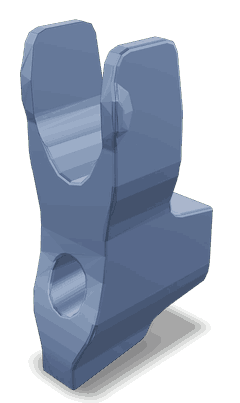

The Cummins Injector Clamp 5419253 is a critical component designed to secure fuel injectors in Cummins engines, ensuring they remain in the correct position for optimal fuel delivery. This clamp is essential for maintaining the integrity and efficiency of the fuel injection system in commercial trucks.

Purpose and Function

The Injector Clamp is designed to hold the fuel injector firmly in place within the engine’s fuel injection system. By securing the injector, it ensures that fuel is delivered consistently and precisely into the combustion chamber. This consistent delivery is vital for the engine’s performance, as it directly influences fuel atomization and combustion efficiency 1.

Key Features

The Cummins Injector Clamp 5419253 is engineered with durability and precision in mind. Constructed from high-quality materials, it is designed to withstand the harsh conditions within a diesel engine. Its design ensures a snug fit around the injector, minimizing the risk of leaks and ensuring that the injector operates within specified parameters. The clamp is compatible with a range of Cummins engines, reflecting its versatile design and engineering excellence 2.

Benefits

Utilizing the Cummins Injector Clamp 5419253 offers several advantages. It contributes to improved fuel efficiency by ensuring that fuel is delivered accurately and consistently. This precision in fuel delivery enhances engine performance, leading to smoother operation and potentially extending the engine’s lifespan. Additionally, the clamp’s design reduces maintenance requirements by minimizing the likelihood of injector displacement or leaks 3.

Installation Process

Installing the Cummins Injector Clamp 5419253 requires careful attention to detail to ensure proper fitting and function. The process involves securing the clamp around the injector and tightening it to the manufacturer’s specifications. It is important to use the correct tools and follow the recommended procedures to avoid damaging the clamp or the injector.

Common Issues and Troubleshooting

Typical problems associated with Injector Clamps include leaks and improper seating. These issues can often be traced back to incorrect installation or wear and tear. Troubleshooting may involve inspecting the clamp for signs of damage, ensuring it is correctly positioned, and tightening it to the specified torque. In some cases, replacing the clamp may be necessary to resolve persistent issues.

Maintenance Tips

Regular maintenance of the Cummins Injector Clamp 5419253 is key to prolonging its lifespan. This includes periodic inspections for signs of wear or damage and cleaning the clamp to remove any buildup that could affect its performance. Adhering to recommended inspection intervals and maintenance procedures can help ensure the clamp continues to function effectively.

Compatibility and Usage

The Cummins Injector Clamp 5419253 is designed for use with specific Cummins engines and fuel injection systems. It is important to consult the manufacturer’s guidelines for compatibility information and any specific usage notes to ensure optimal performance and compatibility with the engine system.

Safety Considerations

When working with Injector Clamps, it is important to observe safety guidelines and precautions. This includes ensuring that the fuel system is depressurized before beginning any work to prevent fuel leaks or accidents. Additionally, handling fuel system components requires care to avoid contamination or damage.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry for producing reliable and efficient engines. The company’s product range includes a variety of engines and components designed to meet the demanding requirements of commercial applications.

Cummins Injector Clamp Part 5419253 Compatibility

The Cummins Injector Clamp part number 5419253 is designed to be compatible with several engine models, ensuring a secure fit and optimal performance. This clamp is integral to the engine’s fuel injection system, providing the necessary support and alignment for the injectors.

Compatible Engines

- QSK95 CM2350 K111

- QSK95 CM2350 K113

These engines, while part of the same family, may have slight variations in their design and specifications. However, the injector clamp part 5419253 is engineered to fit seamlessly with both models, maintaining the integrity and efficiency of the fuel injection system.

Installation and Functionality

When installing the injector clamp part 5419253, it is crucial to follow the manufacturer’s guidelines to ensure proper alignment and secure fastening. This clamp plays a pivotal role in maintaining the correct positioning of the injectors, which is essential for the engine’s performance and longevity.

Importance of Compatibility

Ensuring that the injector clamp is compatible with the specific engine model is vital. Using the correct part number, such as 5419253, guarantees that the clamp will fit correctly and function as intended, avoiding potential issues such as misalignment or improper sealing. This compatibility is particularly important for maintaining the engine’s efficiency and preventing potential failures in the fuel injection system.

Maintenance and Replacement

Regular maintenance of the injector clamp is essential to ensure it remains in good condition. Over time, wear and tear can affect the clamp’s ability to hold the injectors securely, leading to potential performance issues. When replacing the injector clamp, it is recommended to use the specified part number to ensure continued compatibility and functionality with the engine.

Understanding the Role of Part 5419253 Injector Clamp in Engine Systems

Part 5419253, the Injector Clamp, is a fundamental component in the orchestration of various engine systems. Its primary function is to secure the injector in place, ensuring a stable and precise fuel delivery to the combustion chamber. This stability is vital for the consistent performance of the engine.

When considering the camshaft, the Injector Clamp works in harmony to maintain the timing and efficiency of fuel injection. Proper fuel delivery is synchronized with the camshaft’s rotation, optimizing the air-fuel mixture for combustion.

In conjunction with the connecting rod and piston assembly, the Injector Clamp ensures that the fuel is delivered at the precise moment required for optimal combustion. This timing is essential for the efficient transfer of energy from the combustion process to the mechanical movement of the piston, driven by the connecting rod.

The injector kit relies on the Injector Clamp to maintain the integrity of the fuel injection system. By securing the injector, it prevents any misalignment or movement that could disrupt the fuel spray pattern, which is critical for uniform combustion across all cylinders.

In terms of parts and performance, the Injector Clamp contributes to the overall reliability and efficiency of the engine. It ensures that each component within the fuel injection system operates within its designed parameters, leading to enhanced engine performance and longevity.

Lastly, during service and maintenance, the Injector Clamp plays a role in simplifying the process of replacing or adjusting injectors. Its design allows for easy access and secure fitting, which is beneficial for both routine maintenance and performance upgrades.

Conclusion

In summary, the Cummins Injector Clamp 5419253 is a fundamental component that supports the intricate dance of engine systems, ensuring each part operates in unison for optimal engine performance. Its role in securing the injector, maintaining fuel delivery precision, and contributing to engine efficiency and longevity cannot be overstated.

-

Reif, Konrad. Brakes Brake Control and Driver Assistance Systems Function Regulation and Components. Springer, 2014.

↩ -

Bennett, Sean, and Ian Andrew Norman. Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning, 2011.

↩ -

Bennett, Sean, and Ian Andrew Norman. Heavy Duty Truck Systems Fifth Edition. Delmar Cengage Learning, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.