This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

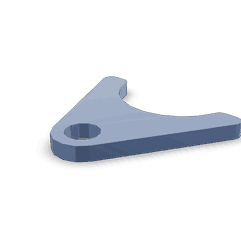

The Cummins 4899498 Clamping Plate is a component designed to enhance the operational efficiency of commercial trucks. It serves a specific function within the truck’s mechanical system, contributing to the overall performance and reliability of the vehicle. Understanding its purpose and significance is key to maintaining and optimizing truck operations.

Basic Concepts of Clamping Plates

A clamping plate is a mechanical component used to secure other parts in place. It operates by applying pressure to hold components together, ensuring they remain fixed during operation. This is achieved through various mechanisms, such as bolts, screws, or other fastening methods. The primary function of a clamping plate is to provide stability and prevent movement or misalignment of parts, which is crucial for the efficient operation of mechanical systems 1.

Purpose of the Cummins 4899498 Clamping Plate

The Cummins 4899498 Clamping Plate plays a role in securing components within the truck’s engine or other systems. Its application is designed to ensure that parts remain in the correct position, facilitating smooth operation and reducing the risk of mechanical failure. By maintaining the integrity of the assembly, this clamping plate contributes to the engine’s efficiency and longevity 2.

Key Features

The Cummins 4899498 Clamping Plate is characterized by several key features that enhance its functionality. These include a durable material composition, typically designed to withstand the rigors of commercial truck operation. The design elements of the plate are tailored to provide a secure fit, ensuring that components are held firmly in place. Additionally, any unique characteristics, such as specific mounting points or reinforcement areas, are incorporated to improve its performance and reliability 3.

Benefits

The use of the Cummins 4899498 Clamping Plate offers several benefits to truck operations. It contributes to improved efficiency by ensuring that components are securely held in place, reducing the likelihood of mechanical issues. The plate’s durable construction enhances the reliability of the truck’s mechanical systems, leading to fewer breakdowns and reduced maintenance costs. Furthermore, its design supports the overall performance of the engine, contributing to a more dependable and efficient vehicle 4.

Installation Process

Installing the Cummins 4899498 Clamping Plate requires careful attention to ensure proper fit and function. The process involves positioning the plate in the designated area, securing it with the appropriate fasteners, and verifying that it holds the components firmly in place. Tools such as wrenches or screwdrivers may be required, depending on the fastening method used. It is important to follow the manufacturer’s guidelines to ensure correct installation 1.

Common Issues and Troubleshooting

Common issues with the Cummins 4899498 Clamping Plate may include loosening of the fasteners, wear and tear on the plate itself, or misalignment of components. Troubleshooting these problems involves checking the tightness of the fasteners, inspecting the plate for damage, and ensuring that all components are correctly aligned. Addressing these issues promptly can prevent more significant mechanical problems and maintain the efficiency of the truck 2.

Maintenance Tips

Regular maintenance of the Cummins 4899498 Clamping Plate is important for ensuring its longevity and optimal performance. This includes periodic inspection for signs of wear or damage, tightening any loose fasteners, and cleaning the plate to remove any debris that may affect its function. Following these maintenance practices can help prevent issues and ensure the clamping plate continues to perform its role effectively 3.

Manufacturer: Cummins

Cummins is a renowned manufacturer in the automotive and heavy-duty truck industry, known for its commitment to quality and innovation. With a history of producing reliable and high-performance components, Cummins has established a strong reputation for excellence. Their focus on advancing technology and meeting the needs of their customers underscores their position as a leader in the industry 4.

Compatibility with Cummins Engines

The Cummins part 4899498, identified as a Clamping Plate, is designed to fit a variety of Cummins engines. This part is integral in securing and stabilizing components within the engine assembly, ensuring optimal performance and longevity. Below is a detailed breakdown of the engines that are compatible with this part, grouped by engine series for clarity.

B Series Engines

- B4.5 RGT

- B6.7 CM2350 B135B

- B6.7 CM2670 B153B

- B6.7 CM2670 B164C

- B6.7 G CMOH6.0 B125

ISB Series Engines

- ISB CM2150

- ISB/ISD4.5 CM2150 B119

- ISB/ISD6.7 CM2150 SN

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

- ISB6.7 G CM2180 B118

ISBE Series Engines

- ISBE CM2150

- ISBE CM800

- ISBE4 CM850

QSB Series Engines

- QSB4.5 CM2250 EC

- QSB4.5 CM850(CM2850)

- QSB6.7 CM2250

- QSB6.7 CM850(CM2850)

- QSB6.7 M CM2250

- QSB7 CM2880 B117

ISD Series Engines

- ISD4.5 CM2220 D108

The Clamping Plate part 4899498 is engineered to ensure a secure fit across these diverse engine models, providing a reliable solution for maintaining engine integrity and performance.

Role of Part 4899498 Clamping Plate in Engine Systems

The 4899498 Clamping Plate is an essential component in the assembly and operation of various engine systems. It is primarily used to secure and maintain the alignment of multiple engine components, ensuring optimal performance and durability.

Integration with the Crankcase and Housing

In the context of the crankcase and housing, the 4899498 Clamping Plate plays a significant role in maintaining the structural integrity of these components. By securely clamping the crankcase to the engine housing, it prevents any misalignment that could lead to increased wear or failure. This secure fit is vital for the smooth operation of the engine, as it ensures that all moving parts within the crankcase are properly aligned and can function without undue stress 1.

Interaction with the Flywheel

When it comes to the flywheel, the 4899498 Clamping Plate is instrumental in ensuring a stable connection between the flywheel and the engine housing. This stability is essential for the efficient transfer of power from the engine to the transmission. A properly clamped flywheel reduces the risk of slippage or misalignment, which can otherwise result in inefficient power delivery and potential damage to the flywheel or other connected components 2.

Contribution to the Long Block Assembly

In the assembly of a long block, which includes the engine block, crankshaft, pistons, and other essential components, the 4899498 Clamping Plate helps in maintaining the precise alignment of these parts. This alignment is crucial for the balanced operation of the engine, as it ensures that all components work in harmony. The clamping plate’s role in this assembly cannot be overstated, as it contributes to the overall stability and performance of the engine 3.

Role in the Breather System

The breather system is another area where the 4899498 Clamping Plate is utilized. By securing the breather components to the engine housing, it ensures that the breather system functions correctly. This system is responsible for releasing pressure build-up within the crankcase, and a secure fit provided by the clamping plate is essential for its efficient operation. Proper functioning of the breather system is important for maintaining engine health and performance 4.

Conclusion

In summary, the Cummins 4899498 Clamping Plate is a versatile component that enhances the functionality and reliability of various engine systems. Its role in securing and aligning critical components ensures that the engine operates smoothly and efficiently. Regular maintenance and proper installation are key to maximizing the benefits of this part, contributing to the overall performance and longevity of commercial trucks.

-

Van Gelder, Kirk T. Fundamentals of Automotive Technology Principles and Practice. Jones Bartlett Learning, 2018.

↩ ↩ ↩ -

Hilgers, Michael. The Drivers Cab. Springer Vieweg, 2022.

↩ ↩ ↩ -

Hick, Hannes, Klaus Kupper, and Helfried Sorger. Systems Engineering for Automotive Powertrain Development. Springer, 2021.

↩ ↩ ↩ -

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill, 2018.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.