3910279

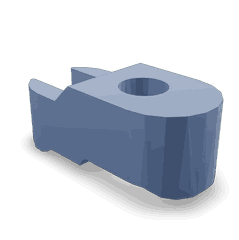

Injector Clamp

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins Injector Clamp 3910279 is a critical component in the fuel injection system of heavy-duty trucks. This article delves into the injector clamp’s function, key features, benefits, and maintenance suggestions, providing a comprehensive overview for professionals and enthusiasts alike.

Basic Concepts of Injector Clamps

An injector clamp is a device that secures the fuel injector within the engine, ensuring a tight seal and proper alignment. This is essential for the efficient operation of the fuel injection system. Typically, the clamp consists of a metal band or bracket that wraps around the injector and is tightened to hold it firmly in place 1.

Role of the 3910279 Injector Clamp in Truck Operation

This Cummins part plays a crucial role in securing the fuel injector within the engine of a heavy-duty truck. By maintaining a secure fit and seal, it contributes to the consistent and precise delivery of fuel into the combustion chamber, which is vital for engine performance and efficiency 2.

Key Features

- Designed specifically for Cummins engines

- Constructed from durable materials to withstand high temperatures and pressures

- Easy to install and remove

- Ensures a reliable seal and proper injector alignment

Benefits

- Enhances the efficiency of the fuel injection system

- Contributes to consistent engine performance

- Reduces the risk of fuel leaks

- Prolongs the lifespan of the fuel injector by providing stable mounting

Troubleshooting and Maintenance

Regular inspection of the injector clamp is recommended to ensure it remains in good condition and properly secured. Signs of wear or damage should be addressed promptly to prevent potential issues with the fuel injection system. Additionally, ensuring the clamp is correctly tightened during installation can help maintain optimal performance 3.

Engine Compatibility

The Injector Clamp 3910279 is designed to fit seamlessly within a range of engine models, ensuring secure and reliable performance. This clamp is integral to the proper functioning of the fuel injection system, providing the necessary support and stability to the injectors.

Compatible Engines

- 6C8.3: The Injector Clamp 3910279 is specifically engineered to fit the 6C8.3 engine, ensuring effective injector security and maintaining the integrity of the fuel delivery system.

- L9.3 L105: Similarly, the Injector Clamp 3910279 is compatible with the L9.3 L105 engine, providing a reliable and durable solution for securing the injectors.

Interaction with Key Engine Components

- Cylinder Block and Cylinder Head: The Injector Clamp works in conjunction with the cylinder block and cylinder head to maintain the structural integrity of the fuel injection system.

- Fuel Injector and Injector Plumbing: By securing the fuel injectors, the clamp plays a significant role in the reliability of the injector plumbing, preventing leaks and ensuring correct fuel delivery.

- Camshaft: In engines where the camshaft controls the fuel injection timing, the Injector Clamp helps maintain the precise alignment needed for synchronized operation.

- On Board Spares and Performance Parts: The Injector Clamp ensures that any new or replacement injectors are installed correctly, which is particularly important in high-performance applications.

Ensuring System Integrity

The Injector Clamp is designed to withstand the high pressures and temperatures within the engine compartment, providing a durable and reliable connection between the fuel injectors and the engine components. Its role in maintaining the integrity of the fuel injection system directly impacts the engine’s overall performance, efficiency, and longevity.

Conclusion

The Cummins Injector Clamp 3910279 is an essential component for the efficient and reliable operation of fuel injectors in heavy-duty trucks. Its design, compatibility with various engine models, and role in maintaining system integrity make it a vital part of the fuel injection system. Regular maintenance and proper installation are key to ensuring optimal performance and longevity of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.