3940639

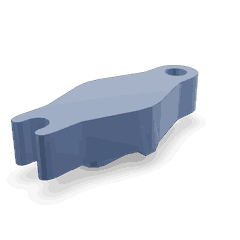

Injector Clamp

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins Injector Clamp (Part #3940639) is a component designed to secure the fuel injector within the engine of heavy-duty trucks. Its role is significant in ensuring the proper functioning of the fuel injection system, which is vital for the overall performance and efficiency of the engine 4.

Basic Concepts of Injector Clamps

An injector clamp is a mechanical device used to hold the fuel injector in place within the engine. It functions by providing a secure connection between the injector and the engine block, which is important for maintaining the integrity of the fuel injection system. The clamp ensures that the injector is properly seated, allowing for accurate fuel delivery and contributing to the engine’s overall performance 1.

Purpose of the Cummins Injector Clamp

The Cummins Injector Clamp plays a role in securing the injector within the engine, which is important for ensuring proper fuel delivery. By maintaining a secure fit, the clamp helps to prevent fuel leaks and ensures that the injector operates within the designed parameters, thereby contributing to engine efficiency and performance 2.

Key Features of the Cummins Injector Clamp

The Cummins Injector Clamp is constructed with high-quality materials to ensure durability and reliability. Its design includes features that enhance its functionality, such as a precise fit that accommodates the specific dimensions of Cummins injectors. The clamp is engineered to withstand the high pressures and temperatures present in diesel engines, ensuring long-term performance 3.

Benefits of Using the Cummins Injector Clamp

Using the Cummins Injector Clamp offers several advantages. It contributes to improved fuel efficiency by ensuring that the injector is securely held in place, which allows for precise fuel delivery. This can lead to enhanced engine performance and increased reliability, as the clamp helps to maintain the integrity of the fuel injection system 4.

Installation Process

Installing the Cummins Injector Clamp requires careful attention to detail to ensure a secure fit. The process involves positioning the clamp over the injector and tightening it to the specified torque. Using the appropriate tools and following best practices during installation is important to avoid damage to the injector or the clamp, and to ensure optimal performance 2.

Troubleshooting Common Issues

Common issues associated with injector clamps include leaks or improper seating of the injector. These problems can often be addressed by inspecting the clamp for damage or wear, ensuring that it is properly tightened, and verifying that the injector is correctly seated. Regular maintenance and inspection can help to identify and resolve these issues before they lead to more significant problems 3.

Maintenance Tips

Regular maintenance of the Cummins Injector Clamp is important to ensure its longevity and optimal performance. This includes periodic inspection for signs of wear or damage, and cleaning the clamp and surrounding areas to prevent the buildup of debris that could affect its function. Following the manufacturer’s recommendations for inspection intervals and maintenance procedures can help to maintain the clamp’s effectiveness 1.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel engines and components. With a history of innovation and a strong reputation in the automotive industry, Cummins is known for producing high-quality, reliable products that meet the demanding requirements of heavy-duty applications. The company’s commitment to excellence is reflected in its extensive product range and the performance of its components, such as the Cummins Injector Clamp 4.

Cummins Injector Clamp 3940639 Compatibility

The Cummins Injector Clamp part number 3940639 is designed to fit a variety of Cummins engines, ensuring a secure and reliable connection for the fuel injectors. Here are the engines with which this part is compatible:

Cummins 6B Series Engines

- 6B5.9: This engine is part of the 6B series and is known for its robust performance and reliability. The injector clamp ensures the injectors are properly secured, maintaining optimal fuel delivery.

Cummins B4.5 Series Engines

- B4.5 RGT: The B4.5 RGT engine benefits from the injector clamp by providing a stable mounting point for the injectors, which is crucial for maintaining engine efficiency and performance.

Cummins ISB Series Engines

- ISB CM550: The ISB CM550 engine is a high-performance model that requires precise injector mounting. The injector clamp ensures that the injectors are held firmly in place, contributing to the engine’s overall reliability.

Cummins ISC Series Engines

- ISC CM554: This engine model is designed for heavy-duty applications. The injector clamp is essential for maintaining the structural integrity of the injectors under high stress conditions.

Cummins ISL Series Engines

- ISL CM554: Similar to the ISC CM554, the ISL CM554 engine also relies on the injector clamp to secure the injectors, ensuring consistent fuel delivery and performance.

Cummins L8 Series Engines

- L8.9: The L8.9 engine is known for its durability and power. The injector clamp plays a critical role in maintaining the alignment and stability of the injectors.

- L8.9 L121: This variant of the L8.9 engine also benefits from the injector clamp, ensuring that the injectors remain securely mounted.

- L9.5 L117: The L9.5 L117 engine requires the injector clamp to maintain the integrity of the injectors, which is vital for its performance.

Cummins QSB Series Engines

- QSB5.9 44 CM550: This engine model is designed for demanding applications. The injector clamp ensures that the injectors are held securely, contributing to the engine’s efficiency and longevity.

Cummins QSC Series Engines

- QSC8.3 CM554: The QSC8.3 CM554 engine relies on the injector clamp to maintain the precise positioning of the injectors, which is essential for optimal performance.

Cummins QSL Series Engines

- QSL9 CM554: The QSL9 CM554 engine is another model that benefits from the injector clamp, ensuring that the injectors are securely mounted and properly aligned.

Role of Part 3940639 Injector Clamp in Engine Systems

The injector clamp, specifically part 3940639, plays a significant role in ensuring the efficient operation of various engine components. Its primary function is to secure the injector in place, maintaining a stable connection within the injector plumbing system. This stability is essential for the precise delivery of fuel into the combustion chamber, directly influencing engine performance 1.

When the injector clamp is properly installed, it ensures that the injector remains aligned with the cylinder head. This alignment is vital for the injector to deliver fuel at the correct timing and pressure, which are important for optimal combustion. In turn, this enhances the overall efficiency and power output of the engine 2.

Moreover, the injector clamp contributes to the integrity of the injector plumbing. By securing the injector firmly, it prevents leaks and ensures that the fuel system operates under the designed pressure conditions. This is particularly important in high-performance engines where even minor leaks can lead to significant performance drops 3.

Additionally, the stable connection provided by the injector clamp reduces the risk of injector movement during engine operation. This is important because any movement can affect the injector’s ability to deliver fuel consistently, potentially leading to misfires or uneven combustion 4.

Conclusion

In summary, the Cummins Injector Clamp (Part #3940639) is integral to maintaining the precise functioning of the injector within the engine system. Its role in securing the injector, ensuring proper alignment with the cylinder head, and maintaining the integrity of the injector plumbing are all important for achieving optimal engine performance. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

-

Gunnar Stiesch, Modeling Engine Spray and Combustion Processes, Springer Verlag, 2003.

↩ ↩ ↩ -

Steve Rendle, Martynn Randall, Haynes Diesel Engine Systems and Data Book, Haynes Publishing, 2000.

↩ ↩ ↩ -

R. Matthew Brach, SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety, SAE International, 2023.

↩ ↩ ↩ -

Clive Gifford, Cars Encyclopedia, DK Publishing, 2014.

↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.