This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

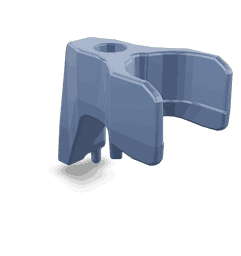

The Injector Clamp 4974971, manufactured by Cummins, is a component designed for use in commercial trucks. Cummins is a well-established name in the automotive industry, known for producing reliable and high-performance diesel engines. This Cummins part plays a role in the operation of diesel engines by securing the fuel injector in place, which is vital for the proper functioning of the fuel injection system 1.

Function and Operation

The Injector Clamp 4974971 operates within the fuel injection system by holding the fuel injector securely in position. This ensures that the injector remains stable during engine operation, allowing for precise fuel delivery. Proper fuel delivery is crucial for efficient combustion, which directly impacts engine performance and fuel efficiency. The clamp’s design allows it to withstand the high pressures and temperatures present in diesel engines, ensuring consistent performance over time 2.

Key Features

The Injector Clamp 4974971 is constructed from high-quality materials, which contribute to its durability and performance. Key features include a robust design that can endure the harsh conditions within a diesel engine. The clamp is engineered to provide a secure fit, minimizing the risk of injector displacement. Additionally, it is designed to be compatible with various fuel injection systems, making it a versatile component for different engine types 3.

Benefits of Using Injector Clamp 4974971

Using the Injector Clamp 4974971 offers several advantages. It contributes to improved fuel efficiency by ensuring that the fuel injector operates within specified parameters. Enhanced engine performance is another benefit, as the secure fitting of the injector allows for optimal fuel combustion. Increased reliability is also a notable advantage, as the clamp’s durable construction helps prevent issues that could arise from injector displacement. These benefits collectively contribute to the overall efficiency and reliability of truck operations.

Installation Process

Installing the Injector Clamp 4974971 requires careful attention to detail. The process involves positioning the clamp around the fuel injector and securing it in place using the appropriate tools. It is important to follow the manufacturer’s guidelines to ensure proper installation. Safety precautions, such as wearing protective gear and ensuring the engine is cool before beginning work, should be observed during the installation process.

Maintenance and Troubleshooting

To ensure the longevity and optimal performance of the Injector Clamp 4974971, regular maintenance is necessary. This includes periodic inspections to check for signs of wear or damage. Common issues that may arise with injector clamps include loosening over time or corrosion. Troubleshooting steps may involve tightening the clamp or, in more severe cases, replacing it. Regular maintenance helps prevent unexpected failures and ensures the clamp continues to perform its function effectively.

Compatibility and Applications

The Injector Clamp 4974971 is designed for use in various types of engines and truck models. It is commonly employed in diesel engines where precise fuel injection is required. The clamp’s compatibility with different fuel injection systems makes it a versatile component for a wide range of applications.

Safety Considerations

When working with injector clamps, it is important to follow safety practices to prevent accidents. Proper handling, installation, and maintenance are crucial to ensure safe operation. This includes using the correct tools, following manufacturer guidelines, and conducting regular inspections to identify any potential issues early.

Cummins Corporation

Cummins Inc. is a leading manufacturer in the commercial truck industry, with a history of producing high-quality diesel engines and components. The company is known for its commitment to quality and innovation, which is reflected in its product range. Cummins’ reputation for reliability and performance makes it a trusted name among commercial truck operators and maintenance professionals.

Compatibility of Injector Clamp Part 4974971 with Cummins Engines

The Injector Clamp part number 4974971, manufactured by Cummins, is designed to fit a variety of Cummins engines. This clamp is crucial for securing the injectors in place, ensuring optimal performance and longevity of the engine components. Below is a detailed overview of the engines with which this part is compatible:

ISX12 Series

- ISX12 CM2350 X102

- ISX12/ISX11.9 CM2250

The ISX12 series engines, including the ISX12 CM2350 X102 and ISX12/ISX11.9 CM2250, are high-performance engines often used in heavy-duty applications. The injector clamp part 4974971 is specifically engineered to fit these engines, providing a secure hold for the injectors and ensuring efficient fuel injection.

ISZ13 Series

- ISZ13 CM2150 Z105

The ISZ13 CM2150 Z105 engine is another variant where the injector clamp part 4974971 is compatible. This engine is designed for applications requiring a balance of power and efficiency, and the clamp ensures that the injectors are properly secured.

QSX11.9 Series

- QSX11.9 CM2250 ECF

The QSX11.9 CM2250 ECF engine benefits from the use of the injector clamp part 4974971. This engine is known for its robust performance and reliability, and the clamp plays a key role in maintaining the integrity of the fuel injection system.

QSZ13 Series

- QSZ13 CM2150 Z101

- QSZ13 CM2150 Z102

The QSZ13 series engines, specifically the QSZ13 CM2150 Z101 and QSZ13 CM2150 Z102, are designed for applications that demand high power output and efficiency. The injector clamp part 4974971 is compatible with these engines, ensuring that the injectors are held firmly in place, which is critical for the engine’s performance.

Z13 Series

- Z13 Z108G

The Z13 Z108G engine is another model where the injector clamp part 4974971 is suitable. This engine is engineered for applications that require a combination of power and fuel efficiency, and the clamp is essential for maintaining the stability of the injectors.

Role of Part 4974971 Injector Clamp in Engine Systems

The 4974971 injector clamp is an essential component in ensuring the secure and efficient operation of fuel injectors within various engine systems. By firmly holding the injector in place, this clamp facilitates optimal fuel delivery and maintains the integrity of the injector plumbing.

Integration with Key Engine Components

-

Cylinder Head and Head: The injector clamp works in conjunction with the cylinder head to ensure that the injector is properly aligned and sealed. This alignment is vital for precise fuel injection into the combustion chamber, enhancing engine performance and efficiency.

-

Injector and Injector Plumbing: The clamp secures the injector to the injector plumbing, preventing any leaks or misalignments that could disrupt fuel flow. This ensures that the fuel is delivered at the correct pressure and timing, which is essential for consistent engine operation.

-

Camshaft and Connecting Rod and Piston: Although the injector clamp does not directly interact with the camshaft, connecting rod, or piston, its role in maintaining proper fuel injection timing indirectly supports the overall synchronization of these components. Accurate fuel delivery contributes to the efficient combustion process, which in turn affects the movement of the piston and the timing of the camshaft.

-

Cylinder: Secure injector placement, facilitated by the clamp, ensures that fuel is injected directly into the cylinder at the optimal moment. This precise timing is crucial for maximizing combustion efficiency and power output.

Conclusion

In summary, the Injector Clamp 4974971 plays a significant role in the coordination and performance of various engine components by ensuring secure and accurate fuel injection. Its robust design, compatibility with multiple engine types, and the benefits it offers in terms of fuel efficiency, engine performance, and reliability make it a critical component in the maintenance and operation of commercial trucks.

References

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.