This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The T Bolt Clamp 2878152, manufactured by Cummins, is a specialized component designed for use in commercial trucks. Cummins, a well-established name in the automotive industry, produces a range of parts that enhance the performance and reliability of commercial vehicles. This part is integral to the maintenance and operation of these trucks, ensuring secure connections in various systems.

Basic Concepts of T Bolt Clamps

A T Bolt Clamp is a mechanical fastener used to secure components in place. It consists of a bolt that passes through a T-shaped slot in the clamp, allowing for adjustable clamping force. This design enables the clamp to hold components firmly without the need for welding or permanent fastening. T Bolt Clamps are commonly used in mechanical systems where components need to be easily removable or adjustable 1.

Purpose of the 2878152 T Bolt Clamp in Truck Operation

The 2878152 T Bolt Clamp plays a specific role in the operation and maintenance of commercial trucks. It is utilized in various truck systems to secure components such as hoses, pipes, and electrical cables. By providing a reliable and adjustable clamping solution, the 2878152 ensures that these components remain in place under varying conditions, contributing to the overall efficiency and safety of the truck 2.

Key Features

The 2878152 T Bolt Clamp boasts several key features that enhance its functionality. It is constructed from high-quality materials, ensuring durability and resistance to corrosion. The design includes a T-shaped slot that allows for easy adjustment of the clamping force, accommodating different component sizes and shapes. Additionally, the clamp features a robust bolt mechanism that provides secure fastening without the risk of over-tightening.

Benefits

Using the 2878152 T Bolt Clamp offers several benefits. It provides improved security of connections, ensuring that components remain firmly in place during operation. The clamp’s durable construction contributes to its longevity, reducing the need for frequent replacements. Furthermore, the ease of installation and adjustment makes it a convenient solution for maintenance tasks, saving time and effort.

Installation Process

Proper installation of the 2878152 T Bolt Clamp involves several steps. Begin by positioning the clamp around the component to be secured. Insert the bolt through the T-shaped slot and tighten it using the appropriate tools. Ensure that the clamping force is sufficient to hold the component in place without causing damage. Follow the manufacturer’s guidelines for torque specifications to achieve the optimal clamping force.

Troubleshooting Common Issues

Common issues with T Bolt Clamps may include loosening over time or difficulty in adjustment. To address these problems, regularly inspect the clamp for signs of wear or damage. If the clamp appears loose, re-tighten it to the recommended torque specification. If adjustment is difficult, ensure that the T-shaped slot is free of debris and that the bolt is not corroded. Replacing worn or damaged components may be necessary to maintain secure connections.

Maintenance Tips

Regular maintenance of the 2878152 T Bolt Clamp is crucial for ensuring its longevity and reliable performance. Inspect the clamp at regular intervals for signs of wear, corrosion, or damage. Clean the T-shaped slot and bolt mechanism to remove any debris that may affect adjustment. Lubricating the bolt with a suitable lubricant can prevent corrosion and ensure smooth operation. Replace the clamp if significant wear or damage is detected to maintain secure connections.

Cummins: A Brief Overview

Cummins is a renowned manufacturer in the commercial truck industry, known for its high-quality products and innovative solutions. With a history spanning several decades, Cummins has established a strong reputation for producing reliable and durable components. Their product range includes engines, powertrains, and aftermarket parts, all designed to enhance the performance and efficiency of commercial vehicles. Cummins’ commitment to quality and innovation makes them a trusted choice for truck manufacturers and operators alike.

Cummins T Bolt Clamp 2878152 in Engine Applications

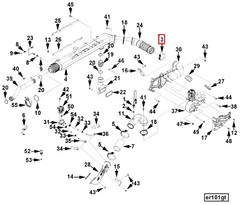

The T Bolt Clamp 2878152, manufactured by Cummins, is a critical component in the assembly and maintenance of several Cummins engine models. This part is integral to ensuring the secure fastening of various engine parts, contributing to the overall stability and performance of the engine.

ISX CM871

In the ISX CM871 engine, the T Bolt Clamp 2878152 is utilized to secure several key components. Its primary function is to maintain the integrity of the engine’s structure by providing a reliable clamping mechanism. This ensures that parts remain firmly in place, reducing the risk of mechanical failure and enhancing the engine’s operational efficiency.

Grouped Applications

The T Bolt Clamp 2878152 is also compatible with other Cummins engines within the same family as the ISX CM871. These engines share similar design principles and component layouts, making the T Bolt Clamp a versatile part across multiple models. Its application in these engines ensures consistent performance and reliability, as it is designed to meet the stringent standards set by Cummins for engine components.

The use of the T Bolt Clamp 2878152 in these engines underscores its importance in maintaining the structural integrity and operational efficiency of the engine. Its design and functionality are tailored to provide a secure and reliable fastening solution, essential for the longevity and performance of the engine 3.

Role of Part 2878152 T Bolt Clamp in Engine Systems

The T Bolt Clamp, identified by part number 2878152, is an essential component in securing various engine system elements, ensuring optimal performance and safety.

In recirculation systems, the T Bolt Clamp is utilized to maintain the integrity of hose connections that facilitate the recirculation of fluids or gases. This is particularly important in systems where precise control of fluid dynamics is required, such as in fuel recirculation or coolant systems. The clamp ensures that hoses remain firmly attached to their respective fittings, preventing leaks and maintaining consistent flow rates.

Within exhaust systems, the T Bolt Clamp plays a significant role in securing connections between exhaust pipes, catalytic converters, and mufflers. This is vital for maintaining the structural integrity of the exhaust path, ensuring that exhaust gases are efficiently directed away from the engine compartment. The clamp helps to withstand the high temperatures and vibrations typical in exhaust systems, contributing to the durability and reliability of the overall setup.

In both applications, the T Bolt Clamp’s design allows for easy installation and removal, facilitating maintenance and repairs. Its robust construction ensures that it can handle the dynamic conditions present in engine systems, providing a secure and lasting connection between components.

Conclusion

The 2878152 T Bolt Clamp is a vital component in the maintenance and operation of commercial trucks and Cummins engines. Its design and functionality ensure secure and reliable connections, contributing to the overall efficiency and safety of the vehicle. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

-

Heavy-Duty Wheeled Vehicles, Haoran Hu, Rudy Smaling, and Simon Baseley, SAE International, 2014.

↩ -

Road and Off-Road Vehicle Dynamics, Moustafa ElGindy and Zeinab ElSayegh, Springer Nature, 2023.

↩ -

Alternative Powertrains and Extensions to the Conventional Powertrain, Michael Hilgers, Springer Nature, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.