3063809

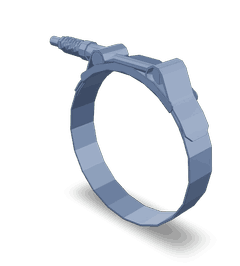

T Bolt Clamp

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Understanding The Cummins 3063809 T Bolt Clamp

Introduction to Cummins 3063809 T Bolt Clamp

The Cummins 3063809 T Bolt Clamp is a critical component in the engine systems of commercial trucks. This article provides a comprehensive understanding of the T Bolt Clamp, its function, and maintenance practices, ensuring engineers and mechanics can effectively utilize and maintain this essential part.

Basic Concepts of a T Bolt Clamp

A T Bolt Clamp, also known as a T-bolt clamp, is a type of fastener that secures two or more parts together by applying pressure through a threaded bolt. The distinctive T-shaped head of the bolt provides a broad surface area for even distribution of the clamping force, ensuring a tight and secure fit. The Cummins 3063809 T Bolt Clamp is designed to withstand the high stresses and demanding conditions of commercial truck engines 1.

Purpose and Role of the Cummins 3063809 T Bolt Clamp

The primary purpose of the Cummins 3063809 T Bolt Clamp is to provide a reliable and secure fastening solution in engine applications. This T Bolt Clamp is typically used to hold engine components together, ensuring that parts remain aligned and do not shift during operation. By maintaining the integrity of engine assemblies, the T Bolt Clamp contributes to the overall performance, efficiency, and longevity of the engine 2.

Operational Insights

In the context of commercial truck engines, the 3063809 T Bolt Clamp is often used to secure various engine components, such as manifolds, brackets, and housings. The clamp’s ability to apply uniform pressure helps prevent leaks, vibrations, and other issues that could compromise engine performance. The robust design of the Cummins 3063809 T Bolt Clamp ensures it can handle the high torque and thermal stresses encountered in heavy-duty applications 3.

Troubleshooting and Maintenance

Proper maintenance of the Cummins 3063809 T Bolt Clamp is crucial for ensuring its longevity and effectiveness. Regular inspections should be conducted to check for signs of wear, corrosion, or damage. If any issues are detected, the clamp should be replaced promptly to avoid potential engine problems.

When troubleshooting, it is essential to verify that the clamp is properly torqued to the manufacturer’s specifications. Over-tightening or under-tightening can lead to failure. Additionally, ensuring that the surfaces being clamped are clean and free of debris will help maintain a secure connection.

Cummins: A Leader in Engine Technology

Cummins is a renowned manufacturer of engines and related components for commercial trucks and heavy-duty vehicles. With a legacy of innovation and quality, Cummins products are trusted by professionals worldwide. The Cummins 3063809 T Bolt Clamp exemplifies the company’s commitment to providing reliable and durable components that meet the rigorous demands of the trucking industry.

Maintenance Best Practices

To maximize the lifespan and performance of the Cummins 3063809 T Bolt Clamp, follow these maintenance best practices:

- Regular Inspections: Conduct routine visual inspections to check for signs of wear, corrosion, or damage.

- Proper Torque: Ensure the clamp is tightened to the manufacturer’s specified torque settings to avoid over-tightening or under-tightening.

- Clean Surfaces: Keep the surfaces being clamped clean and free of debris to maintain a secure connection.

- Lubrication: Apply appropriate lubricants to the clamp threads and surfaces to reduce friction and wear.

- Replacement: Replace the clamp if any damage or significant wear is detected to prevent potential engine issues.

By adhering to these maintenance practices, engineers and mechanics can ensure the Cummins 3063809 T Bolt Clamp continues to perform reliably, contributing to the overall efficiency and durability of commercial truck engines.

Cummins T Bolt Clamp 3063809 Compatibility

The Cummins T Bolt Clamp part number 3063809 is a versatile component designed to fit a variety of Cummins engines. This clamp is essential for securing and stabilizing various parts within the engine system, ensuring optimal performance and reliability. Below is a detailed breakdown of the engines with which this part is compatible:

K Series Engines

- K19

- K38

- K50

The K series engines, including the K19, K38, and K50, are known for their robust design and efficiency. The T Bolt Clamp 3063809 is engineered to fit these models, providing the necessary support and stability for their components.

KTA19 Series Engines

- KTA19GC

- KTA19GC CM558

The KTA19GC and KTA19GC CM558 engines benefit from the T Bolt Clamp 3063809, which helps maintain the integrity of the engine’s internal components, ensuring smooth operation and longevity.

QSB6.7 Series Engines

- QSB6.7 M CM2250

The QSB6.7 M CM2250 engine is designed for heavy-duty applications, and the T Bolt Clamp 3063809 is a critical component in maintaining the structural integrity of this powerful engine.

QSC8.3 Series Engines

- QSC8.3 CM850 (CM2850)

The QSC8.3 CM850 (CM2850) engine is another model that is compatible with the T Bolt Clamp 3063809, ensuring that all parts are securely fastened and properly aligned.

QSK19 Series Engines

- QSK19 CM2350 K105

- QSK19 CM2350 K114

- QSK19 CM2350 K144G

- QSK19 CM500

- QSK19 CM850 MCRS

- QSK19G

The QSK19 series engines, including the CM2350 K105, K114, K144G, CM500, CM850 MCRS, and QSK19G, all require the T Bolt Clamp 3063809 for proper assembly and maintenance. This clamp is crucial for securing various parts within these engines.

QSK60 Series Engines

- QSK60 CM500

- QSK60 CM850 MCRS

The QSK60 series engines, such as the CM500 and CM850 MCRS, are designed for high-performance applications. The T Bolt Clamp 3063809 is an essential component for these engines, ensuring that all parts are securely fastened and properly aligned.

QSK78 Series Engines

- QSK78 CM500

The QSK78 CM500 engine is another model that is compatible with the T Bolt Clamp 3063809, ensuring that all parts are securely fastened and properly aligned.

QSM11 Series Engines

- QSM11 CM570

The QSM11 CM570 engine is designed for specific applications and is compatible with the T Bolt Clamp 3063809, ensuring that all parts are securely fastened and properly aligned.

QST30 Series Engines

- QST30 CM2350 T101

- QST30 CM552

The QST30 series engines, including the CM2350 T101 and CM552, are designed for various applications and are compatible with the T Bolt Clamp 3063809, ensuring that all parts are securely fastened and properly aligned.

QSW36 Series Engines

- QSW36

The QSW36 engine is another model that is compatible with the T Bolt Clamp 3063809, ensuring that all parts are securely fastened and properly aligned.

Role of Part 3063809 T Bolt Clamp in Engine Systems

The T Bolt Clamp, identified by part number 3063809, is an essential component in securing various connections within engine systems. Its application spans across multiple components, ensuring robust and reliable performance.

Air System Components

In the air system, the T Bolt Clamp is utilized to secure connections in the air intake manifold, air crossover assembly, and air crossover mounting. It plays a significant role in maintaining the integrity of the air transfer connection and the air crossover tube mounting. Additionally, it is employed in the charge air assembly cooler and the aftercooler, ensuring that these components remain firmly attached and function efficiently.

Exhaust and Turbocharger Systems

Within the exhaust and turbocharger systems, the T Bolt Clamp is integral to the exhaust manifold / turbocharger and its mounting. It secures the turbocharger arrangement and is crucial in the turbocharger hose and clamp setup. The clamp ensures that the turbocharger hose clamps are tightly fastened, preventing any leaks or disconnections that could affect engine performance.

Cooling and Plumbing Systems

In the cooling and plumbing systems, the T Bolt Clamp is used in the coolant system kit and the radiator plumbing connection. It helps in maintaining the secure attachment of components in the step hoses kit, ensuring that the coolant flow is uninterrupted and efficient.

Overhaul and Performance Kits

For overhaul kits and performance parts, the T Bolt Clamp is a key component in ensuring that all connections are secure. It is particularly important in the PDC (Performance Diesel Component) kits, where precise and reliable connections are essential for optimal performance.

Intercooler and Air Crossover Connections

The T Bolt Clamp is also employed in the intercooler and various air crossover connections. It ensures that these components are securely fastened, contributing to the overall efficiency and reliability of the engine system.

Conclusion

In summary, the T Bolt Clamp (part 3063809) is a versatile and essential component in various engine systems, providing secure and reliable connections across a wide range of applications. Proper maintenance and adherence to best practices are crucial for ensuring the longevity and performance of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.