This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

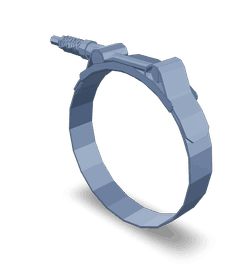

The 3177337 T-Bolt Clamp, manufactured by Cummins, is a specialized component designed for use in commercial trucks. Cummins, a well-established name in the automotive industry, is known for its commitment to quality and innovation. This part serves a vital function in truck maintenance and operation by securely fastening hoses and pipes, ensuring the integrity of fluid transfer systems within the vehicle.

Basic Concepts of T-Bolt Clamps

A T-Bolt Clamp is a type of hose clamp that uses a T-shaped bolt to create a secure seal around hoses and pipes. It operates by tightening the bolt, which compresses a band around the hose, creating a tight seal. This design is prevalent in the automotive industry due to its reliability and ease of use. T-Bolt Clamps are favored for their mechanical simplicity and effectiveness, offering a robust solution for securing hoses in various applications. They provide a consistent clamping force, which is crucial for maintaining the integrity of fluid transfer systems 1.

Purpose of the 3177337 T-Bolt Clamp in Truck Operation

This Cummins part plays a specific role in the operation of commercial trucks by ensuring the secure attachment of hoses and pipes within the vehicle’s fluid transfer systems. This clamp contributes to the efficiency and safety of truck systems by maintaining a reliable seal, which prevents leaks and ensures consistent fluid flow. Its application is critical in environments where vibrations and temperature fluctuations are common, as it provides a durable and secure fastening solution 2.

Key Features of the 3177337 T-Bolt Clamp

The 3177337 is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials, ensuring resistance to corrosion and wear. The design includes a T-shaped bolt that allows for easy adjustment and a secure fit. Additionally, the clamp features a band that is engineered to provide uniform pressure around the hose, maximizing the seal’s effectiveness. These features contribute to the clamp’s reliability and longevity in demanding commercial truck applications 3.

Benefits of Using the 3177337 T-Bolt Clamp

Incorporating this part into truck systems offers several benefits. Its design promotes improved reliability by ensuring a secure and consistent seal around hoses. The clamp’s ease of installation reduces downtime during maintenance procedures. Furthermore, its durability and resistance to environmental factors contribute to lower maintenance requirements, making it a cost-effective solution for commercial truck operators.

Installation Process

Installing the 3177337 requires careful attention to detail to ensure optimal performance. Begin by selecting the appropriate clamp size for the hose diameter. Position the clamp around the hose, ensuring it is centered and aligned correctly. Use the T-shaped bolt to tighten the clamp, applying even pressure to achieve a secure seal. It is important to avoid over-tightening, which can damage the hose. Following these steps will ensure the clamp is installed correctly, providing a reliable seal for the truck’s fluid transfer systems.

Troubleshooting Common Issues

Common problems associated with T-Bolt Clamps include leaks due to improper installation or wear and tear. To troubleshoot these issues, first, inspect the clamp for signs of damage or misalignment. Ensure the clamp is correctly sized for the hose and that it is tightened to the manufacturer’s specifications. If leaks persist, the clamp may need to be replaced. Regular inspections can help identify wear early, allowing for timely maintenance or replacement.

Maintenance Tips

To prolong the lifespan of the 3177337 and ensure consistent performance, regular maintenance is recommended. Inspect the clamp and hose for signs of wear or damage at regular intervals. Clean the clamp and surrounding areas to remove any debris that could affect its performance. Lubricating the T-shaped bolt can facilitate easier adjustment and prevent seizing. Following these maintenance tips will help maintain the clamp’s effectiveness and reliability in commercial truck applications.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s commitment to excellence is evident in its wide range of products, which are designed to meet the demanding requirements of commercial vehicle operators. Cummins’ dedication to quality and innovation ensures that its components, like the 3177337, deliver reliable performance and durability in various applications.

T-Bolt Clamp Part 3177337 Compatibility with Cummins Engines

The T-Bolt Clamp part 3177337, manufactured by Cummins, is a critical component designed to ensure secure fastening and stability in various engine configurations. This part is engineered to fit seamlessly within the K19 and K38 engine families, providing essential support and alignment for engine components.

K19 Engine Family

In the K19 engine family, the T-Bolt Clamp part 3177337 plays a pivotal role in maintaining the integrity of the engine’s internal structure. It is specifically designed to fit the unique design and specifications of the K19 engines, ensuring that all parts are held firmly in place. This clamp is crucial for securing various engine components, contributing to the overall performance and longevity of the engine.

K38 Engine Family

Similarly, within the K38 engine family, the T-Bolt Clamp part 3177337 is integral to the engine’s operational efficiency. This part is tailored to meet the specific requirements of the K38 engines, providing a reliable fastening solution that enhances the engine’s structural integrity. The clamp’s design ensures that it can withstand the operational stresses and demands of the K38 engines, thereby contributing to their durability and performance.

Grouping of Engines

Both the K19 and K38 engines benefit from the use of the T-Bolt Clamp part 3177337, as it is designed to fit within the broader specifications of these engine families. This compatibility allows for a standardized approach to engine maintenance and repair, simplifying the process for technicians and ensuring that the engines operate at peak efficiency. The clamp’s design and material are optimized to provide a secure and reliable fit across both engine families, making it a versatile and essential component in Cummins’ engine lineup.

Role of Part 3177337 T-Bolt Clamp in Engine Systems

The 3177337 is an essential component in the assembly and maintenance of various engine systems, particularly those involving air filtration and intake. Its primary function is to secure and maintain the integrity of connections within the air cleaner system, ensuring efficient airflow and system reliability.

Air Cleaner System Integration

In the air cleaner system, the T-Bolt Clamp is used to fasten the air cleaner to its base or housing. This secure attachment prevents any dislodgement during engine operation, which could lead to air leaks and reduced filtration efficiency. The clamp ensures a tight seal, maintaining the designed airflow path and protecting the engine from ingesting unfiltered air.

Air Cleaner Connection

The T-Bolt Clamp plays a significant role in connecting the air cleaner to other components such as the air intake manifold or throttle body. This connection is vital for maintaining a sealed pathway for air to travel from the air cleaner to the engine. The clamp’s ability to provide a snug fit helps in preventing air leaks, which can affect engine performance and fuel efficiency.

Air Cleaner Plumbing

Within the air cleaner plumbing, which includes hoses and tubes that direct air flow, the T-Bolt Clamp is used to secure these components to the air cleaner and other parts of the engine system. This ensures that the air flow remains consistent and unimpeded, contributing to the overall efficiency of the engine’s air intake system.

Air Tube Arrestor Cleaner

In systems where an air tube arrestor is used—a device that prevents flames from traveling back into the air intake system—the T-Bolt Clamp is employed to secure the arrestor to the air cleaner or other components. This not only ensures the arrestor remains in place but also maintains the integrity of the air flow system, enhancing safety and performance.

General Air Cleaner Applications

Across various air cleaner applications, the T-Bolt Clamp is a versatile component that ensures all connections within the air cleaner system are secure. Whether it’s attaching the air cleaner to its base, connecting hoses, or securing arrestors, the clamp’s role is fundamental in maintaining the system’s operational integrity.

Air Plumbing

In the broader context of air plumbing within engine systems, the T-Bolt Clamp is instrumental in securing all air-related components. This includes not only the air cleaner but also any additional components that are part of the air intake system. The clamp’s reliability in providing a secure connection is key to the system’s performance and durability.

Conclusion

In summary, the 3177337 is a vital component in ensuring the secure and efficient operation of air cleaner systems within engine assemblies. Its applications across various connections and components highlight its importance in maintaining the integrity and performance of engine air intake systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.