This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The T Bolt Clamp 3633995, manufactured by Cummins, is a specialized component designed for use in commercial trucks. Cummins, a well-established name in the automotive industry, is known for its commitment to quality and innovation. This Cummins part is integral to the maintenance and operation of commercial trucks, ensuring the secure attachment of various components within the vehicle’s systems.

Basic Concepts of T Bolt Clamps

T Bolt Clamps are mechanical fasteners used to secure components in various systems. They are characterized by a T-shaped bolt that threads into a corresponding T-slot, providing a firm grip. These clamps are widely used in mechanical systems for their reliability and ease of use. They function by applying pressure to hold components in place, ensuring stability and integrity within the system 1.

Purpose of the T Bolt Clamp 3633995 in Truck Operation

The T Bolt Clamp 3633995 plays a specific role in the operation and maintenance of commercial trucks. It is utilized in areas where secure attachment is necessary to maintain system integrity. This includes applications in the engine compartment, exhaust systems, and other critical areas where components must remain firmly in place under various operating conditions. The clamp ensures that parts are held securely, reducing the risk of detachment or misalignment, which could lead to operational issues 2.

Key Features of the T Bolt Clamp 3633995

The T Bolt Clamp 3633995 is designed with several features that enhance its performance and durability. It is constructed from high-quality materials that offer resistance to corrosion and wear, ensuring longevity in demanding environments. The design includes enhancements for better grip, such as a textured surface on the T-bolt, which provides additional security. Additionally, the clamp is engineered for ease of installation, allowing for quick and efficient attachment and removal when necessary.

Benefits of Using the T Bolt Clamp 3633995

Incorporating the T Bolt Clamp 3633995 into truck maintenance and repair offers several advantages. It contributes to improved safety by ensuring that components remain securely attached, reducing the risk of accidents due to part detachment. The reliability of the clamp enhances the overall efficiency of truck operations, as it minimizes the need for frequent adjustments or replacements. Furthermore, the ease of installation and removal facilitates quicker maintenance procedures, contributing to operational efficiency 3.

Installation and Usage Guidelines

Proper installation of the T Bolt Clamp 3633995 involves several steps to ensure optimal performance. Begin by identifying the correct T-slot for attachment. Insert the T-bolt into the slot and turn it clockwise to secure the components. Ensure that the clamp is tightened to the manufacturer’s specifications to achieve the desired level of pressure without over-tightening, which could damage the components or the clamp itself. Regular checks should be performed to ensure that the clamp remains securely in place and that there are no signs of wear or damage.

Troubleshooting and Maintenance Suggestions

Common issues with T Bolt Clamps may include loosening over time due to vibrations or wear. Regular inspections are recommended to identify any signs of loosening or damage. If a clamp is found to be loose, it should be re-tightened to the specified torque. In cases where damage is observed, replacement of the clamp may be necessary to maintain system integrity. Proper maintenance practices, such as keeping the clamp and surrounding areas clean and free of debris, can help ensure longevity and optimal performance.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is renowned for its commitment to quality, innovation, and customer satisfaction. The company offers a wide range of products for various industries, including automotive, construction, and power generation. Cummins’ dedication to excellence is evident in its products, which are designed to meet the demanding requirements of their applications.

Cummins T Bolt Clamp 3633995 Compatibility

The Cummins T Bolt Clamp part number 3633995 is designed to fit seamlessly with a variety of Cummins engines, ensuring secure fastening and reliable performance. This part is integral in maintaining the structural integrity of the engine by securing components together effectively.

K50 Series Engines

The T Bolt Clamp 3633995 is specifically engineered to integrate with the K50 series engines. These engines are known for their robust design and efficiency, making them a popular choice in various industrial applications. The clamp’s precision fit ensures that it can withstand the operational stresses and pressures inherent in these engines, providing a dependable connection that enhances overall engine performance.

Grouping of Compatible Engines

While the K50 series is a notable example, the T Bolt Clamp 3633995 is also compatible with other Cummins engines that share similar design and operational characteristics. This compatibility extends to engines within the same family or those that have been designed with similar fastening requirements. By ensuring a secure fit, the clamp helps maintain the alignment and stability of critical engine components, contributing to the longevity and reliability of the engine.

The T Bolt Clamp 3633995 is a testament to Cummins’ commitment to quality and precision in engine components, providing a reliable fastening solution that meets the demands of various industrial and commercial applications.

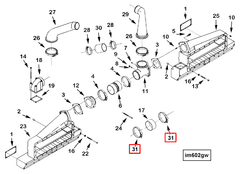

Role of Part 3633995 T Bolt Clamp in Engine Systems

The part 3633995 T Bolt Clamp is integral to the secure and efficient operation of various engine components. It is specifically designed to provide a robust connection in systems where air flow and pressure integrity are paramount.

Air Connection

In the context of an air connection, the T Bolt Clamp ensures a leak-free seal between different sections of the air intake system. This is essential for maintaining the correct air-fuel ratio, which directly influences engine performance and efficiency.

Air Intake Manifold

When fitted to an air intake manifold, the T Bolt Clamp plays a significant role in securing the manifold to the engine. This connection is vital for distributing air evenly to each cylinder, ensuring consistent combustion across the engine.

Air Manifold

For the air manifold, the T Bolt Clamp is used to connect various sections of the manifold, facilitating smooth air flow from the air filter to the cylinders. This setup is crucial for optimal engine breathing and performance.

Air Manifold Assembly

In an air manifold assembly, the T Bolt Clamp is employed to join multiple components, such as the air intake manifold and the turbocharger. This assembly ensures that the air flow is directed efficiently, minimizing turbulence and maximizing engine efficiency.

Arrangement with Turbocharger

When arranging components with a turbocharger, the T Bolt Clamp secures the connections between the turbocharger and the air intake system. This ensures that the pressurized air from the turbocharger is delivered without leaks, enhancing overall engine performance.

Manifold Connections

The T Bolt Clamp is also used in manifold connections to ensure that all sections of the manifold are securely joined. This is important for maintaining consistent air pressure and flow throughout the engine system.

Air Intake System

Finally, in the broader air intake system, the T Bolt Clamp is utilized to connect various components, ensuring that the air path from the filter to the cylinders is sealed and efficient. This contributes to the overall reliability and performance of the engine.

Conclusion

The T Bolt Clamp 3633995 is a critical component in the maintenance and operation of commercial trucks, particularly in ensuring the secure attachment of various engine components. Its design, featuring high-quality materials and enhanced grip, contributes to the reliability and efficiency of truck operations. Proper installation and maintenance of this part are essential to ensure optimal performance and longevity of the engine systems it supports.

-

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩ -

Sobey, E. (2009). A Field Guide to Automotive Technology. Chicago Review Press.

↩ -

Kasab, J., & Strzelec, A. (2020). Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.