This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

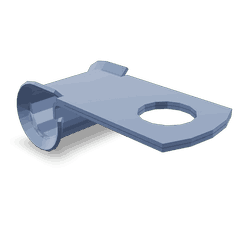

The Tube Clamp 4935913 by Cummins is a specialized component designed to secure and connect tubing systems in commercial trucks. Its role is significant in maintaining the integrity and efficiency of various truck systems, ensuring that fluid and gas lines remain securely fastened and properly aligned.

Basic Concepts of Tube Clamps

Tube clamps are mechanical fasteners used to join and secure tubing in automotive and industrial applications. They function by compressing the tubing against a fixed surface, creating a tight seal that prevents leaks and ensures the smooth flow of fluids or gases. Tube clamps are versatile and can be used in a wide range of applications, from fuel lines to hydraulic systems 1.

Purpose of the 4935913 Tube Clamp in Truck Operations

This Cummins part is specifically designed to play a role in the operation of commercial trucks by securing various tubing systems. It is applied in systems such as fuel lines, hydraulic systems, and coolant circuits. By providing a reliable connection, the clamp helps maintain the efficiency and safety of these critical systems.

Key Features of the 4935913 Tube Clamp

This part is constructed with high-quality materials to ensure durability and performance. Its design includes a robust clamping mechanism that provides a secure fit around the tubing. The clamp is engineered to withstand the rigors of commercial truck operations, offering resistance to corrosion and mechanical stress. Unique attributes such as adjustable bands and serrated surfaces enhance its clamping efficiency and ease of use.

Benefits of Using the 4935913 Tube Clamp

Utilizing this part offers several advantages. Its design allows for easy installation, reducing downtime during maintenance procedures. The clamp’s reliability in securing connections contributes to the overall efficiency and safety of truck operations. Additionally, its robust construction ensures long-term performance, minimizing the need for frequent replacements.

Installation and Usage Guidelines

Proper installation of this part involves several steps. First, ensure the tubing is clean and free of debris. Position the clamp around the tubing and tighten it using the provided tool until the desired compression is achieved. It is important to follow best practices, such as not over-tightening the clamp, to avoid damaging the tubing. Safety considerations include wearing appropriate personal protective equipment and ensuring the work area is free of hazards.

Troubleshooting Common Issues

Common issues with tube clamps may include leaks or loose connections. To address these problems, first, inspect the clamp and tubing for signs of damage or wear. Ensure the clamp is properly tightened and that the tubing is seated correctly within the clamp. If leaks persist, consider replacing the clamp or inspecting the surrounding system for additional issues.

Maintenance Tips for Longevity

To ensure the longevity and optimal performance of this part, regular maintenance is recommended. This includes periodic inspection for signs of wear, corrosion, or damage. Cleaning the clamp and tubing can prevent buildup that may affect performance. Replacement guidelines suggest monitoring the condition of the clamp and tubing, replacing them as needed to maintain system integrity.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins serves commercial truck, bus, construction, agricultural, and industrial markets. The company is renowned for its commitment to reliability and performance, making it a trusted name in the industry 2.

Cummins Tube Clamp 4935913 Compatibility

The Cummins Tube Clamp part number 4935913 is designed to fit seamlessly with a range of Cummins engines, ensuring secure and reliable connections for various fluid lines and components. This tube clamp is engineered to meet the rigorous demands of heavy-duty applications, providing durability and ease of installation.

B6.7 and G Engines

The B6.7 and G engines, both known for their robust performance and reliability, benefit from the precise fit and functionality of the 4935913 tube clamp. This part is crucial in maintaining the integrity of fluid lines, preventing leaks, and ensuring optimal engine operation.

CMOH6.0 and B125 Engines

Similarly, the CMOH6.0 and B125 engines are compatible with the 4935913 tube clamp. These engines, designed for demanding applications, rely on high-quality components to maintain their efficiency and longevity. The tube clamp’s design ensures a secure fit, reducing the risk of fluid line failure and enhancing overall engine performance.

Role of Part 4935913 Tube Clamp in Engine Systems

This part is an essential component in various engine systems, ensuring secure and efficient connections between different parts. Its application spans across several key areas, enhancing the overall performance and reliability of the engine.

Breather Systems

In breather systems, the 4935913 Tube Clamp is used to connect the breather tubes to the crankcase. This connection allows for the release of pressure build-up within the crankcase, preventing damage to seals and gaskets. The clamp ensures a tight seal, minimizing the risk of leaks and maintaining the integrity of the breather system.

Crankcase Ventilation

For crankcase ventilation, the Tube Clamp plays a significant role in securing the hoses that carry crankcase gases to the intake manifold or another designated area for safe disposal. This process helps in reducing emissions and improving engine efficiency. The clamp’s reliable hold ensures that the ventilation system operates without interruptions, contributing to a cleaner and more efficient engine operation.

Plumbing Systems

In plumbing systems, the 4935913 Tube Clamp is utilized to connect various fluid lines, such as coolant or oil passages. These connections are vital for maintaining the proper flow of fluids throughout the engine, ensuring optimal temperature regulation and lubrication. The clamp’s durability and secure fit prevent leaks, which could lead to engine overheating or insufficient lubrication.

Turbocharger Systems

Within turbocharger systems, the Tube Clamp is employed to connect the intercooler piping and other critical hoses. This ensures that the airflow through the turbocharger is maintained at the correct pressure and temperature, enhancing the turbocharger’s performance and longevity. The clamp’s ability to withstand high pressures and temperatures makes it ideal for these applications, ensuring that the turbocharger operates efficiently and reliably.

Conclusion

Overall, the 4935913 Tube Clamp is a versatile component that significantly contributes to the functionality and efficiency of various engine systems. Its reliable performance in securing connections across different applications underscores its importance in maintaining engine health and performance.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.