This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

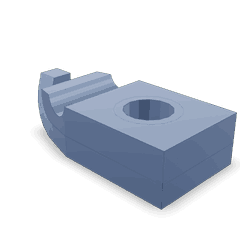

The Tube Clamp 4936461, manufactured by Cummins, is a component designed to enhance the efficiency and reliability of commercial truck operations. Cummins, a well-established name in the commercial truck industry, produces a range of parts and systems aimed at improving truck performance and durability. This Cummins part plays a significant role in securing and connecting various tubing systems within commercial trucks.

Basic Concepts of Tube Clamps

Tube clamps are mechanical devices used to secure and connect tubing in automotive and industrial applications. They function by providing a secure, leak-proof connection that can withstand various pressures and environmental conditions. Tube clamps are preferred in applications where flexibility, ease of installation, and the ability to disconnect and reconnect tubing are required. They are commonly used in fuel lines, brake systems, and hydraulic systems, among others 1.

Purpose of the 4936461 Tube Clamp in Truck Operations

This part is specifically designed for use in commercial truck operations. It plays a role in securing and connecting tubing systems that are integral to the operation of various truck components. This includes applications in fuel delivery systems, hydraulic lines, and other fluid transfer systems. By ensuring a secure connection, the clamp contributes to the overall reliability and safety of the truck’s operation 2.

Key Features of the 4936461 Tube Clamp

The 4936461 Tube Clamp is constructed with durability and performance in mind. It is made from high-quality materials that offer resistance to corrosion and wear, ensuring long-term reliability. The clamping mechanism is designed to provide a tight, secure fit around the tubing, minimizing the risk of leaks. Additionally, the clamp features an easy-to-use design that allows for quick installation and removal, facilitating maintenance and repair processes 3.

Benefits of Using the 4936461 Tube Clamp

Utilizing this part offers several advantages. Its robust construction and secure clamping mechanism contribute to improved system reliability. The ease of installation and removal not only saves time during maintenance but also reduces the likelihood of installation errors. Furthermore, the clamp’s design allows for efficient maintenance, helping to minimize downtime and operational disruptions 4.

Installation and Usage Guidelines

Proper installation of the 4936461 Tube Clamp is crucial for ensuring its effectiveness and longevity. Begin by ensuring the tubing is clean and free of any debris. Position the clamp around the tubing and secure it using the provided mechanism, ensuring a tight fit. It is important to follow manufacturer guidelines for torque specifications to avoid over-tightening, which could damage the tubing or the clamp itself. Always wear appropriate personal protective equipment during installation to ensure safety 5.

Troubleshooting Common Issues

Common issues with tube clamps may include leaks, difficulty in installation, or clamp failure. To address leaks, first, ensure the clamp is properly installed and tightened according to specifications. If leaks persist, inspect the tubing for damage or debris that may be preventing a secure seal. Difficulty in installation may be resolved by ensuring the tubing is properly prepared and that the clamp is correctly positioned. Clamp failure could indicate material fatigue or incorrect use; replacing the clamp with a new one may be necessary 6.

Maintenance Tips

Regular maintenance of the 4936461 Tube Clamp is key to ensuring its longevity and performance. Inspect the clamp and tubing regularly for signs of wear, corrosion, or leaks. Clean the clamp and surrounding areas to remove any buildup that could affect performance. Lubricating moving parts, if applicable, can also help maintain the clamp’s functionality. Following these maintenance practices can help prevent unexpected failures and extend the service life of the clamp 7.

Compatibility and Applications

The 4936461 Tube Clamp is designed for use in various commercial truck systems, including fuel lines, hydraulic systems, and other fluid transfer applications. It is important to ensure compatibility with the specific tubing and system requirements of the truck to guarantee optimal performance and safety 8.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a strong reputation in the commercial truck industry, Cummins is committed to innovation, quality, and customer satisfaction. The company’s extensive product range and focus on technological advancement make it a preferred choice for commercial truck operators and manufacturers 9.

Tube Clamp 4936461 Compatibility with Cummins Engines

The Tube Clamp part number 4936461 is a critical component designed to secure and stabilize various tubes and hoses within the engine system. This part is engineered to fit seamlessly with specific Cummins engines, ensuring optimal performance and reliability.

QSB4.5 Series

The Tube Clamp 4936461 is compatible with the following Cummins QSB4.5 engines:

- QSB4.5 CM2250 EC

- QSB4.5 CM850 (CM2850)

In the QSB4.5 series, the Tube Clamp is used to maintain the integrity of the engine’s cooling and fuel systems. It ensures that all connected tubes and hoses remain securely fastened, preventing leaks and maintaining system pressure. This is crucial for the efficient operation of the engine, as any failure in the tube connections can lead to significant performance issues.

The Tube Clamp 4936461 is designed to withstand the high temperatures and pressures typical of these engines, ensuring long-term durability and reliability. Its precise fit and robust construction make it an essential component for maintaining the structural integrity of the engine’s tubing system 10.

Role of Part 4936461 Tube Clamp in Plumbing and Fuel Systems

Plumbing Systems

In plumbing systems, the Tube Clamp 4936461 is instrumental in ensuring secure and leak-free connections between pipes and fittings. Its primary function is to maintain the integrity of the plumbing network by providing a robust clamping mechanism that withstands various pressures and temperatures. This is particularly important in applications where water flow must be consistent and uncontaminated. The Tube Clamp ensures that joints remain tight, preventing any potential leaks that could lead to water damage or inefficient system performance. Additionally, it simplifies the installation and maintenance processes, allowing for quick adjustments and replacements without the need for specialized tools 11.

Fuel Systems

Within fuel systems, the Tube Clamp 4936461 plays a significant role in maintaining the safety and efficiency of fuel delivery. It is used to secure fuel lines to various components such as fuel pumps, injectors, and tanks. The clamp’s design ensures that fuel lines remain firmly in place, reducing the risk of disconnections that could lead to fuel leaks or engine performance issues. In high-pressure fuel systems, such as those found in modern automotive and aerospace applications, the Tube Clamp provides the necessary stability to handle the dynamic forces and vibrations encountered during operation. This reliability is essential for maintaining consistent fuel flow, which is vital for engine performance and overall system safety 12.

Conclusion

The 4936461 Tube Clamp is a vital component in the maintenance and operation of commercial trucks, particularly those equipped with Cummins engines. Its robust construction, ease of installation, and compatibility with various systems make it an indispensable part for ensuring the reliability and efficiency of truck operations. Regular maintenance and proper installation are key to maximizing the benefits of this part, contributing to the overall performance and safety of commercial trucks.

-

Trzesniowski, M. (2023). The Complete Vehicle. Springer Nature.

↩ -

Reif, K. Ed. (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ -

Bartz, W. J. (2019). Engine Oils and Automotive Lubrication Mechanical Engineering Book 80. CRC Press.

↩ -

Reif, K. (2015). Automotive Mechatronics. Springer Vieweg.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5660084.

↩ -

Trzesniowski, M. (2023). The Complete Vehicle. Springer Nature.

↩ -

Reif, K. Ed. (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ -

Bartz, W. J. (2019). Engine Oils and Automotive Lubrication Mechanical Engineering Book 80. CRC Press.

↩ -

Reif, K. (2015). Automotive Mechatronics. Springer Vieweg.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5660084.

↩ -

Trzesniowski, M. (2023). The Complete Vehicle. Springer Nature.

↩ -

Reif, K. Ed. (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.