This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

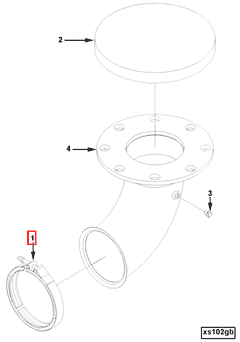

The 186917 V Band Clamp is a component manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industry. This clamp is specifically designed for use in commercial trucks, where it plays a significant role in maintaining the integrity of the exhaust and intake systems.

Basic Concepts of V Band Clamps

V Band Clamps are a type of fastening device used to secure pipes and fittings in various systems. They consist of a band that wraps around the pipe and a bolt that pulls the band tight, creating a secure seal. This design allows for easy installation and removal without the need for specialized tools. V Band Clamps are commonly used in automotive and industrial applications due to their efficiency and reliability in creating leak-free connections 1.

Role of V Band Clamp 186917 in Truck Operation

In the context of truck operation, the V Band Clamp 186917 functions by securing connections within the truck’s exhaust and intake systems. It ensures that these connections remain tight and leak-free, which is vital for the efficient operation of the engine. By maintaining a secure seal, the clamp helps to prevent the escape of exhaust gases and ensures that the intake system draws in air efficiently 2.

Key Features

The V Band Clamp 186917 boasts several key features that enhance its performance and durability. It is constructed from high-quality materials, which contribute to its strength and resistance to corrosion. The design of the clamp includes a band and a bolt mechanism that allows for quick and easy installation. Additionally, the clamp is engineered to provide a robust seal, ensuring that connections remain secure under various operating conditions 3.

Benefits

The use of the V Band Clamp 186917 in truck operations offers several advantages. It contributes to improved efficiency by ensuring secure and leak-free connections in the exhaust and intake systems. This can lead to better engine performance and fuel efficiency. Furthermore, the clamp’s design allows for easy maintenance and replacement, reducing downtime and maintenance costs. Its durability and reliability also enhance the overall reliability of the truck’s systems 4.

Troubleshooting and Maintenance

Common issues with V Band Clamps may include leaks due to improper installation or wear and tear over time. Regular inspection and maintenance are recommended to ensure optimal performance. This includes checking for signs of wear, ensuring that the clamp is properly tightened, and replacing the clamp if necessary. Troubleshooting steps may involve re-tightening the clamp or replacing damaged components to resolve issues.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established itself as a trusted name in the automotive industry, known for its commitment to innovation, quality, and customer satisfaction. The company’s expertise in diesel engine manufacturing and its dedication to advancing technology have made it a leader in the field.

V Band Clamp Compatibility with Cummins Engines

This Cummins part, with the part number 186917, is a versatile component designed to fit a variety of Cummins engines. This clamp is essential for securing hoses and pipes, ensuring a tight and leak-proof connection. Below is a detailed description of how this part fits with the specified engines:

G Series Engines

- G855

- G855 CM558

- GTA855 CM558 (CM2358)

- G101

The V Band Clamp is compatible with the G series engines, providing a reliable seal for various applications within these models.

I Series Engines

- ISG12 CM2880 G107

- ISM CM570

- ISM11 CM876 SN

- ISX CM570

- ISX15 CM2250 SN

- ISZ13 CM2150 Z105

This clamp is also suitable for the I series engines, ensuring a secure fit for the hoses and pipes used in these models.

K Series Engines

- K19

- K38

- K50

The V Band Clamp is designed to fit the K series engines, providing a dependable seal for various connections.

KTA Series Engines

- KTA38GC CM558

This clamp is compatible with the KTA38GC CM558 engine, ensuring a secure and leak-proof connection.

L, M, and N Series Engines

- L10 CELECT

- M11 CELECT

- M11 CELECT PLUS

- N14 CELECT

- N14 CELECT PLUS

- N14 G

- N14 MECHANICAL

The V Band Clamp fits seamlessly with the L, M, and N series engines, providing a reliable seal for the hoses and pipes used in these models.

NH/NT Series Engines

- NH/NT 855

This clamp is compatible with the NH/NT 855 engine, ensuring a secure and leak-proof connection.

QSG Series Engines

- QSG12 CM2880 G112

- QSG12/X12 CM2350 G110

The V Band Clamp is designed to fit the QSG series engines, providing a dependable seal for various connections.

QSK Series Engines

- QSK19 CM850 MCRS

- QSK19G

This clamp is compatible with the QSK series engines, ensuring a secure and leak-proof connection.

Role of Part 186917 V Band Clamp in Engine Systems

The 186917 V Band Clamp is integral to the secure and efficient connection of various components within engine systems. It ensures that connections remain tight and leak-free, enhancing overall performance and reliability.

Exhaust System Integration

In the exhaust system, the V Band Clamp is used to connect the exhaust outlet to the muffler and the exhaust connection to the turbocharger. This secure fitting prevents exhaust leaks, which can lead to performance issues and increased emissions. The clamp also facilitates easier maintenance and replacement of components such as the particulate trap system and the particulate trap bypass valve.

Air Intake and Turbocharger Connections

For the air intake system, the V Band Clamp plays a significant role in connecting the air intake connection to the turbocharger and the air crossover connection to the air manifold. This ensures a consistent airflow, which is essential for optimal turbocharger performance.

Aftercooler and Conversion Kit Applications

In systems utilizing an aftercooler, the V Band Clamp is employed in the aftercooler conversion kit to connect the aftercooler to the air crossover assembly. This connection is vital for maintaining the efficiency of the cooling process, which directly impacts engine performance.

Comprehensive System Arrangement

The V Band Clamp is also utilized in the arrangement of engine mounting parts kit and the exhaust system kit. It provides a robust connection between the exhaust outlet connection and the turbocharger exhaust connection, ensuring that the entire exhaust kit operates seamlessly.

Additional Connections and Hardware

Furthermore, the V Band Clamp is essential in the EBM connection and various other connection points throughout the engine system. It is included in hardware kits to ensure all connections are secure, from the turbocharger to the exhaust outlet.

The use of the V Band Clamp in these applications underscores its versatility and importance in maintaining the integrity and performance of engine systems.

Conclusion

The 186917 V Band Clamp is a critical component in the maintenance and operation of Cummins engines. Its role in securing connections within the exhaust and intake systems ensures efficient engine performance and reliability. The clamp’s design, featuring a band and bolt mechanism, allows for easy installation and removal, making it a practical choice for both maintenance and replacement. Additionally, its compatibility with a wide range of Cummins engines highlights its versatility and importance in the automotive industry.

-

MJ Nunney, Light and Heavy Vehicle Technology, Fourth Edition, Butterworth-Heinemann, 2007.

↩ -

Gunnar Stiesch, Modeling Engine Spray and Combustion Processes, Springer Verlag, 2003.

↩ -

Haoran Hu, Simon J Baseley and Xubin Song, Advanced Hybrid Powertrains for Commercial Vehicles Second Edition, SAE International, 2021.

↩ -

Dominique Bonneau, Aurelian Fatu and Dominique Souchet, Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings, Wiley-ISTE, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.