This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 114421 Clip, manufactured by Cummins, is a component designed for use in commercial truck operations. Cummins, a well-established name in the industry, produces a range of parts and systems that contribute to the efficiency and reliability of heavy-duty trucks. This Cummins part is one such component, playing a specific role in the functionality of these vehicles.

Purpose and Function

The 114421 Clip serves a specialized function within truck operations. It is utilized in various systems where secure fastening and reliable connections are required. This clip is integral to maintaining the integrity of certain assemblies, ensuring that components remain in place under operational conditions. Its applications span across different subsystems within the truck, contributing to the overall performance and safety of the vehicle 1.

Key Features

The 114421 Clip is characterized by its robust design and material composition. Crafted from high-quality materials, it is engineered to withstand the rigors of commercial truck environments. Its design incorporates features that enhance its grip and stability, ensuring a secure fit in its intended applications. These attributes contribute to the clip’s durability and effectiveness in maintaining connections over time 2.

Benefits

Incorporating the 114421 Clip into truck operations offers several advantages. It enhances safety by ensuring that critical components remain securely fastened, reducing the risk of detachment or failure during operation. Additionally, its reliable performance contributes to the efficiency of the truck, as it helps maintain the integrity of the systems it supports. The durability of the clip also means reduced maintenance needs, providing long-term value to fleet operators 3.

Installation Process

Installing the 114421 Clip requires adherence to a specific procedure to ensure proper functionality. The process involves identifying the correct location for the clip, preparing the area for installation, and securing the clip in place using the appropriate tools. Detailed instructions should be followed to avoid common installation errors that could affect the clip’s performance.

Maintenance and Troubleshooting

Regular maintenance of the 114421 Clip is important to ensure its continued effectiveness. This includes periodic inspections for signs of wear or damage and replacing the clip if necessary. Troubleshooting common issues, such as loose connections or failure to secure components, involves checking the clip’s condition and ensuring it is correctly installed. Proper maintenance practices help extend the lifespan of the clip and maintain the reliability of the truck’s systems.

Safety Considerations

When handling and installing the 114421 Clip, it is important to observe safety guidelines to prevent accidents. This includes using personal protective equipment, ensuring the truck is properly secured before beginning work, and following all manufacturer recommendations for installation and maintenance. Adhering to these safety practices helps protect both the technician and the vehicle from potential hazards.

Environmental Impact

The production, use, and disposal of the 114421 Clip have environmental considerations. Efforts should be made to minimize waste during manufacturing and to recycle or dispose of the clip responsibly at the end of its service life. Cummins and other industry stakeholders are increasingly focused on reducing the environmental footprint of their products, including through sustainable manufacturing practices and recycling programs.

Cummins Overview

Cummins is a leading manufacturer in the commercial truck industry, known for its comprehensive range of engines, components, and systems. With a history of innovation and quality, Cummins has established a strong reputation for producing reliable and efficient products. Their commitment to excellence is reflected in the design and performance of components like the 114421 Clip, which contribute to the safety, efficiency, and reliability of commercial trucks.

Role of Part 114421 Clip in Engine Systems

The 114421 Clip is an essential component in the assembly and maintenance of various engine systems. Its primary function is to securely fasten and connect different parts, ensuring the integrity and efficiency of the engine’s operation.

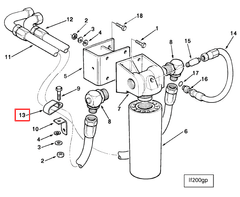

Aeroquip Lubricating Oil Hose

In the Aeroquip lubricating oil hose system, the 114421 Clip is used to connect the hose to the oil pump and other critical components. This ensures a leak-free connection, maintaining the proper flow of lubricating oil throughout the engine.

Base Parts

For base parts, the clip is utilized to attach various components to the engine block. This includes securing oil lines, breather tubes, and other essential connections, ensuring they remain firmly in place during engine operation.

Compressor Connection

In compressor systems, the 114421 Clip plays a role in connecting the compressor to the lubrication system. This secure attachment is vital for the efficient transfer of lubricants, which are necessary for the compressor’s smooth operation.

Filter and Full Flow Oil System

Within the filter and full flow oil system, the clip is employed to connect the lubricating oil filter to the oil lines. This ensures that the oil passes through the filter without any leaks, maintaining the cleanliness and quality of the oil circulating in the engine.

Lube Filter Hose

The lube filter hose relies on the 114421 Clip to create a secure connection between the filter and the oil lines. This is important for maintaining the pressure and flow rate of the lubricant, which is essential for the engine’s performance.

Lubricating Oil Filter

In the lubricating oil filter assembly, the clip is used to attach the filter to the engine’s oil system. This secure connection ensures that the filter can effectively remove contaminants from the oil, prolonging the engine’s lifespan.

Oil Pan

The oil pan connections often utilize the 114421 Clip to attach drain plugs, oil lines, and other components. This ensures that the oil pan remains sealed and that the oil can be efficiently drained during maintenance.

Oil Pump Plumbing

In oil pump plumbing, the clip is used to connect the pump to the oil lines and other components. This secure attachment is necessary for the pump to deliver oil to various parts of the engine under pressure.

Crankcase Breather

The crankcase breather system uses the 114421 Clip to connect the breather to the engine block and other components. This ensures that pressure is released from the crankcase in a controlled manner, preventing oil leaks and maintaining engine efficiency.

Marine Gear Oil Cooler

For marine gear oil coolers, the clip is employed to connect the cooler to the oil lines. This secure connection is vital for the efficient cooling of the gear oil, which is crucial for the performance of marine engines.

Stratoflex Lube Oil Hose

In Stratoflex lube oil hose systems, the 114421 Clip is used to connect the hose to various components. This ensures a reliable and leak-free connection, maintaining the proper flow of lubricants in the engine.

T C Cooler Hose

The T C cooler hose system utilizes the clip to connect the cooler to the oil lines. This secure attachment is important for the efficient cooling of the transmission fluid, which is essential for the transmission’s performance.

Water Bypass Pipe

In water bypass pipe systems, the 114421 Clip is used to connect the pipe to the engine’s cooling system. This ensures a secure and leak-free connection, maintaining the proper flow of coolant and preventing overheating.

Conclusion

The 114421 Clip, manufactured by Cummins, is a critical component in the maintenance and operation of commercial truck engines. Its robust design, reliable performance, and ease of installation make it an invaluable part for ensuring the safety, efficiency, and reliability of heavy-duty trucks. Proper maintenance and adherence to safety guidelines are essential for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.