This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 178123 Clip is a component utilized in the operation of commercial trucks. This clip serves a specific function within the truck’s system, contributing to the vehicle’s overall performance and reliability. Understanding its purpose and significance is important for maintaining and optimizing the truck’s operation.

Purpose and Function

The 178123 Clip plays a role in securing and organizing various components within the truck’s engine compartment. It is designed to hold wires, hoses, or other parts in place, ensuring they do not interfere with the engine’s operation or become damaged. By maintaining the proper positioning of these components, the clip contributes to the truck’s efficient and safe operation 1.

Key Features

The 178123 Clip is characterized by its robust design and durable material composition. Typically made from high-quality plastic or metal, it is engineered to withstand the harsh conditions of the engine compartment, including heat, vibration, and exposure to various chemicals. Its design allows for easy attachment and removal, facilitating maintenance and repairs 2.

Benefits

The use of the 178123 Clip offers several advantages. It enhances the reliability of the truck by ensuring that critical components remain in their intended positions. This can lead to improved engine performance and reduced risk of damage. Additionally, the clip’s design allows for straightforward installation, potentially saving time and labor costs for fleet operators 3.

Installation Process

Installing the 178123 Clip involves identifying the correct location within the engine compartment where it is needed. The clip should be securely fastened to hold the targeted components in place. It is important to follow the manufacturer’s guidelines for installation to ensure proper function and durability. Tools required may include a screwdriver or pliers, depending on the specific design of the clip.

Maintenance and Troubleshooting

Regular inspection of the 178123 Clip is recommended to ensure it remains in good condition and continues to perform its function effectively. Look for signs of wear, damage, or loosening, and address any issues promptly to prevent potential problems. If the clip becomes damaged or fails to hold components securely, it should be replaced to maintain the truck’s operational integrity.

Compatibility and Applications

The 178123 Clip is designed to fit specific models of trucks and engine types. It is important to verify compatibility with the truck’s make and model to ensure proper fit and function. Application notes provided by the manufacturer can offer guidance on the correct usage and installation of the clip.

Safety Considerations

When working with the 178123 Clip, it is important to observe safety practices to protect oneself and ensure the truck’s safe operation. This includes wearing appropriate personal protective equipment, ensuring the engine is cool before beginning work, and following all manufacturer guidelines for handling and installation.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of engine and component products. With a history of innovation and quality, Cummins has established a reputation for reliability and performance in the trucking sector. The company’s product lineup includes engines, filtration systems, and aftermarket parts, all designed to meet the demanding requirements of commercial transportation.

Engine Compatibility with Part 178123

The part number 178123, a Clip manufactured by Cummins, is designed to integrate seamlessly with a variety of engine models. This clip is engineered to ensure proper assembly and functionality across different engine types, providing a reliable connection point.

L10 MECHANICAL

In the L10 MECHANICAL engine, the clip is used to secure various components, ensuring that they remain firmly in place during operation. Its placement is critical for maintaining the integrity of the engine’s structure and performance.

NH/NT 855

For the NH/NT 855 engines, the clip plays a vital role in the assembly of the engine’s internal and external components. Its design allows for easy installation and removal, facilitating maintenance and repair processes.

V903

Similarly, in the V903 engine, the clip is utilized to secure and stabilize components, contributing to the overall efficiency and longevity of the engine. Its strategic placement is crucial for the engine’s operational reliability.

By providing a secure fit across these engines, the 178123 clip ensures that the engine operates smoothly and efficiently, minimizing the risk of component failure and enhancing overall performance.

Role of Part 178123 Clip in Engine Systems

The Part 178123 Clip is instrumental in ensuring the secure and efficient operation of various components within engine systems. Its applications span across multiple subsystems, enhancing both functionality and reliability.

Fuel System Integration

In the fuel system, the Part 178123 Clip is employed in the fuel plumbing to maintain the integrity of connections. It secures the fuel suction tube and fuel supply tube, ensuring a consistent fuel flow to the engine. Additionally, it plays a role in the fuel bypass mounting and fuel check valve assemblies, where it helps prevent fuel backflow and maintains system pressure. The clip is also utilized in the fuel drain tube to ensure proper drainage and prevent fuel accumulation, which could lead to system malfunctions.

Check Valve and Non-Return Valve Applications

The clip is vital in the mounting of check valves and non-return valves. By securing these valves in place, it ensures that fluids flow in the intended direction, preventing reverse flow which could compromise engine performance. This is particularly important in the check valve mounting and fuel check valve setups, where precise fluid control is essential.

Cooling System Contributions

In the cooling system, the Part 178123 Clip is used in the water transfer tube and water tube support to maintain the structural integrity of these components. It ensures that coolant flows efficiently through the water outlet and water outlet connection, aiding in the consistent cooling of engine components. The clip also supports the water transfer (front) tube, which is critical for maintaining optimal engine temperature.

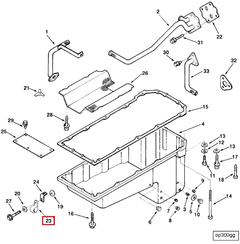

Structural and Mounting Roles

The clip is also employed in various mounting applications, such as the cylinder block and oil mounting pan. It secures the mounting baffle and tubing, ensuring that these components remain in place under operational stress. Furthermore, it is used in the OG tube support and resistor corrosion protection setups, where it helps maintain the structural stability and longevity of these elements.

Intake Manifold and Additional Applications

In the intake manifold, the Part 178123 Clip ensures that the manifold remains securely attached to the engine, facilitating efficient air intake. It also plays a role in the supply tube mounting for fuel, where it ensures that the fuel supply tubes are correctly positioned and maintained.

Overall, the Part 178123 Clip is a versatile component that enhances the reliability and efficiency of various engine systems through secure and stable connections.

Conclusion

The Cummins 178123 Clip is a critical component in the operation and maintenance of commercial trucks. Its robust design, ease of installation, and versatile applications across various engine systems make it an invaluable part for ensuring the reliability and efficiency of truck engines. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

-

Modern Automotive Electrical Systems, Pedram Asef, Sanjeevikumar Padmanaban, and Andrew Lapthorn, Wiley, 2022.

↩ -

The Automotive Body, Frederick F. Ling, Springer Science, 2011.

↩ -

Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles, Andrew Brown Jr, National Academy of Sciences, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.