This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

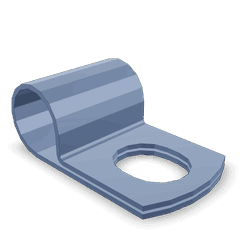

The Cummins 218052 Clip is a component designed for use in commercial trucks, manufactured by Cummins, a well-established name in the automotive industry. This clip serves a specific function within the truck’s operational framework, contributing to the overall efficiency and reliability of the vehicle. Cummins is renowned for its commitment to quality and innovation in the production of automotive parts.

Basic Concepts Related to Clips

In the context of automotive components, a clip is a small but vital part that secures and holds various parts together. Clips are utilized across different systems in a vehicle to ensure that components remain in place and function correctly under various conditions. They are designed to withstand significant stress and environmental factors, ensuring the longevity and performance of the vehicle 1.

Purpose of the 218052 Clip

The Cummins 218052 Clip plays a role in the operation of a truck by securing specific components within the vehicle’s system. It interacts with various parts, ensuring they are held firmly in place, which is crucial for the truck’s performance and safety. The clip’s design allows it to fit snugly into place, providing a secure connection that can endure the rigors of commercial use 2.

Key Features

The Cummins 218052 Clip is characterized by several key features that enhance its functionality and durability. It is made from high-quality materials, ensuring it can withstand the harsh conditions often encountered in commercial trucking. The design of the clip includes specific elements that allow for easy installation and removal, without compromising on the security of the connection it provides. Additionally, the clip may feature unique characteristics that enhance its performance, such as a specific shape or surface treatment that improves its grip and durability 3.

Benefits

Utilizing the Cummins 218052 Clip offers several advantages. Its durable construction ensures long-lasting performance, even under demanding conditions. The ease of installation reduces downtime during maintenance, allowing for quicker and more efficient repairs. Furthermore, the reliability of the clip in harsh environments contributes to the overall safety and efficiency of the truck.

Installation Process

Installing the Cummins 218052 Clip requires following a specific procedure to ensure it is securely and correctly placed. The process involves identifying the correct location for the clip, using the appropriate tools to install it, and ensuring it is firmly in place. Precautions should be taken to avoid damaging the clip or the surrounding components during installation.

Common Issues and Troubleshooting

Common problems associated with the Cummins 218052 Clip may include improper installation, wear and tear, or damage due to environmental factors. Troubleshooting these issues involves inspecting the clip for signs of damage or wear, ensuring it is correctly installed, and replacing it if necessary. Addressing these issues promptly can prevent more significant problems and ensure the continued reliability of the truck.

Maintenance Tips

Regular maintenance of the Cummins 218052 Clip is crucial for ensuring its longevity and optimal performance. This includes periodic inspections to check for signs of wear or damage, cleaning the clip and its surrounding area to prevent buildup that could affect its function, and replacing the clip if it shows signs of significant wear or if it becomes damaged. Following these maintenance tips can help maintain the efficiency and safety of the truck.

Cummins as a Manufacturer

Cummins has a long-standing reputation in the automotive industry for producing high-quality parts and components. With a history of innovation and a commitment to quality, Cummins offers a wide range of products designed to meet the needs of commercial trucking. Their parts, including the 218052 Clip, are engineered to provide reliable performance and durability, contributing to the efficiency and safety of commercial vehicles.

Compatibility

The Cummins part 218052, a Clip, is designed to fit a variety of Cummins engines, ensuring secure and reliable performance across different engine models. Here is a detailed breakdown of the engines with which this clip is compatible:

B6.7 Series

- B6.7 CM2670 B153B

- B6.7 CM2670 L134C

F3.8 and F4.5 Series

- F3.8 CM2620 F137B

- F4.5 CM2620 F139B

ISB/ISD Series

- ISB/ISD 4.5 CM2150 B119

- ISB/ISD 6.7 CM2150 SN

ISBE Series

- ISBE CM2150

- ISBE4 CM850

K Series

- K38

- K50

KTA19 Series

- KTA19GC

- KTA19GC CM558

L Series

- L10 CELECT

- L10 MECHANICAL

M Series

- M11 CELECT

N14 Series

- N14 MECHANICAL

NH/NT Series

- NH/NT 855

QSB Series

- QSB4.5 CM850 (CM2850)

- QSB6.7 CM850 (CM2850)

- QSB6.7 M CM2250

- QSB7 CM2880 B117

QSK Series

- QSK19 CM2350 K114

- QSK19 CM850 MCRS

- QSK50 CM2150 K107

QST Series

- QST30 CM552

This clip is engineered to meet the specific needs of these engines, providing essential support and functionality across a diverse range of applications.

Role of Part 218052 Clip in Engine Systems

The part 218052 Clip is integral to the secure and efficient operation of various engine systems. It is employed in the Air Compressor to ensure that connections remain tight, preventing air leaks that could reduce compressor efficiency. In the Air Intake Connection, this clip plays a role in maintaining a sealed pathway for air entering the engine, which is essential for optimal combustion.

For the Base Parts, the 218052 Clip is used to fasten components securely, ensuring that they remain in place under the dynamic conditions of engine operation. In the Cam Follower Cover, it helps in keeping the cover properly attached, which is important for the lubrication and smooth operation of the camshaft.

The Campaign Coolant Float Kit utilizes this clip to secure float mechanisms, ensuring accurate coolant level readings and efficient cooling system performance. In the Crankcase Breather system, the clip is vital for maintaining the integrity of the breather arrangement, allowing for proper ventilation of the crankcase without compromising engine seals.

In the Electronic Control Module Wiring Harness and Engine Control Module, the 218052 Clip is used to secure wiring connections, ensuring reliable electrical conductivity and preventing potential short circuits. For the Engine Lubricating Primer and Engine Oil Primer Plumbing, it ensures that oil lines are securely connected, facilitating consistent lubrication throughout the engine.

Within the Fuel Filter Plumbing, Fuel Plumbing, and Fuel Transfer Kit, this clip secures fuel lines, preventing leaks and ensuring a steady fuel supply to the engine. The Fuel Transfer Pump and Fuel Tubes also benefit from the secure connections provided by this clip, enhancing fuel delivery reliability.

The Full Flow Oil Filter system uses the 218052 Clip to maintain secure connections in the oil filtration process, ensuring clean oil circulation. In the Kim Hotstart Plumbing, it secures components necessary for easy engine starting in cold conditions.

For the Kit Cooling system, this clip ensures that cooling system components are firmly in place, promoting efficient heat dissipation. In the Oil Bypass Filter arrangement, it secures bypass lines, ensuring that oil filtration standards are maintained.

The Rear Engine Support system employs this clip to fasten support components, ensuring structural integrity. Lastly, in Wiring Accessories and the Wiring Harness, the 218052 Clip is used to secure electrical connections, ensuring a reliable and safe electrical system within the engine.

Conclusion

The Cummins 218052 Clip is a vital component in the operation and maintenance of commercial trucks, offering durability, ease of installation, and reliable performance across a wide range of Cummins engines. Regular maintenance and proper installation are key to ensuring the longevity and efficiency of this part, contributing to the overall safety and performance of the vehicle.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.