This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

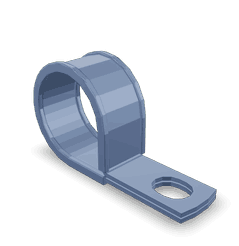

The Cummins 3018309 Clip is a specialized component designed for use in commercial trucks. It serves a specific function within the vehicle’s systems, contributing to the overall efficiency and reliability of truck operations. Understanding the role and significance of this part is important for maintaining and optimizing truck performance.

Purpose and Function

This Cummins part is utilized in various applications within a truck’s system. It plays a role in securing components, ensuring they remain in place under operational conditions. The clip is often found in engine components and exhaust systems, where it helps maintain the integrity of connections and joints. By securing these parts, the clip contributes to the smooth operation of the truck, reducing the risk of component failure or detachment during use 1.

Key Features

The 3018309 Clip is characterized by its robust design and material composition. It is typically made from durable materials that can withstand the high stress and temperatures encountered in truck engines and exhaust systems. The clip’s design allows for a secure fit, ensuring that components remain firmly in place. Its construction is tailored to endure the rigors of commercial truck use, providing reliability over extended periods 2.

Benefits

Using the 3018309 Clip offers several advantages. Its durable construction ensures longevity, reducing the frequency of replacements. The clip is designed for ease of installation, allowing mechanics to quickly and efficiently secure components. Additionally, by ensuring components are properly held in place, the clip can contribute to improved performance and reliability of the truck’s systems 3.

Installation Process

Installing the 3018309 Clip requires attention to detail to ensure a proper fit. Begin by identifying the correct location for the clip within the truck’s system. Use the appropriate tools to place the clip over the designated component, ensuring it is aligned correctly. Apply gentle pressure to secure the clip in place, verifying that it holds the component firmly without causing damage. Follow manufacturer guidelines for any specific installation steps or torque specifications.

Common Applications

The 3018309 Clip is commonly applied in engine components and exhaust systems of commercial trucks. It is used to secure hoses, pipes, and other components, ensuring they remain in place under operational conditions. This clip is vital in maintaining the integrity of these systems, contributing to the overall performance and reliability of the truck.

Troubleshooting and Maintenance

When troubleshooting issues related to the 3018309 Clip, begin by inspecting the clip for signs of wear or damage. Ensure it is properly installed and secured. If the clip appears worn or damaged, replacement may be necessary to maintain system integrity. Regular maintenance checks can help identify potential issues early, ensuring the clip continues to perform its function effectively.

Safety Considerations

When handling and installing the 3018309 Clip, it is important to observe safety guidelines to protect mechanics and operators. Wear appropriate personal protective equipment (PPE) to safeguard against injuries. Ensure the truck is properly secured and the engine is off before beginning any installation or maintenance work. Follow all manufacturer safety recommendations to ensure a safe working environment.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company offers a wide range of products designed to meet the demanding requirements of commercial vehicle applications, ensuring reliability and performance.

Cummins Engine Part 3018309 Clip Compatibility

The 3018309 Clip is designed to fit a variety of Cummins engines, ensuring a secure and reliable connection in various applications. This clip is engineered to provide stability and durability, making it an essential component for maintaining engine integrity.

Compatible Engines

- 4B3.9, 6B5.9, 6C8.3

- B4.5 CM2350 B129B, B6.7 CM2670 B153B

- D4.0 CM2620 D103B, F3.8 CM2350 F120B, F3.8 CM2350 F128C, F3.8 CM2620 F137B, F4.5 CM2620 F139B

- ISB CM550, ISB CM850, ISB4.5 CM2350 B104, ISC CM850

- ISF2.8 CM2220 F129, ISF3.8 CM2220 AN, ISF3.8 CM2350 F109, ISF4.5 CM2220 F123

- ISL9 CM2150 SN, ISX12 G CM2180 EJ, K19, NH/NT 855

- QSB5.9 44 CM550, QSB5.9 CM850, QSB6.7 CM850(CM2850)

This clip is compatible with a broad range of Cummins engines, including both diesel and gas models. It is particularly useful in applications where secure fastening is critical, such as in the engine’s internal and external components.

Role of Part 3018309 Clip in Engine Systems

The 3018309 Clip is integral to the secure assembly and operation of various engine components. Its applications span across multiple systems, ensuring the integrity and efficiency of the engine’s performance.

Aftercooler Drain Valve Mounting

The Clip is used in the mounting of the aftercooler drain valve, facilitating a secure attachment that prevents leaks and ensures the valve operates correctly to drain condensed water from the aftercooler.

Air Intake Connection

In the air intake system, the Clip secures connections between the air intake manifold and other components, maintaining a sealed pathway for air to enter the engine efficiently.

Air Intake Manifold

Within the air intake manifold, the Clip plays a role in securing various connections and components, ensuring a smooth and uninterrupted flow of air into the engine cylinders.

Check Valve and Manifold Press Systems

The Clip is essential in the installation of check valves, including those within the manifold press system. It ensures these valves are firmly in place, allowing for the correct direction of fluid or air flow and preventing backflow.

Compressor Air Inlet Plumbing

For the compressor air inlet plumbing, the Clip secures connections, contributing to the efficient compression of air before it enters the engine, which is vital for optimal engine performance.

Crankcase Breather and Plumbing

In the crankcase breather system, including its plumbing, the Clip ensures that connections are tight. This is important for releasing pressure from the crankcase and allowing for the safe venting of gases.

Fuel System Components

Within the fuel system, the Clip is used in the secure attachment of the fuel filter, fuel pump, and fuel tubing. This ensures a reliable fuel supply to the engine, free from leaks or interruptions.

Front Retro-Breather and Lubricating Oil Filter

The Clip aids in the secure mounting of the front retro-breather and the lubricating oil filter, ensuring these components function correctly to maintain engine health and performance.

Manifold Assembly and Pressure Systems

Across manifold assembly tubes, manifold press assembly tubes, and related mounting and tubing components, the Clip ensures all connections are secure. This is key for maintaining the correct pressure and flow within these systems, directly impacting engine efficiency and performance.

Oil Fill Arrangement and Valve Cover Breather Kit

Finally, in the oil fill arrangement and valve cover breather kit, the Clip secures components, ensuring the engine’s lubrication system operates efficiently and without leaks.

Overall, the role of the 3018309 Clip in these various engine systems underscores its importance in maintaining the structural integrity and operational efficiency of the engine.

Conclusion

The Cummins 3018309 Clip plays a vital role in the secure assembly and operation of various engine components across multiple systems. Its robust design and durable material composition ensure longevity and reliability, contributing to the overall efficiency and reliability of truck operations. Proper installation, regular maintenance, and adherence to safety guidelines are essential for maximizing the benefits of this part.

-

SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety, R. Matthew Brach, SAE International, 2023

↩ -

Automotive Heating Ventilation and Air Conditioning, Quansheng Zhan, Shengbo Eben, Li Kun Deng, Jones Bartlett Learning, 2018

↩ -

Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems, Owen C Duffy and Gus Wright, Jones Bartlett Learning, 2016

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.