This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3031618 Clip is a specialized component designed for use in heavy-duty truck systems. This clip serves a specific function within the assembly and operation of truck components, contributing to the overall efficiency and reliability of the vehicle. Cummins, a well-established manufacturer in the automotive industry, produces this clip as part of its extensive range of high-quality truck parts 1.

Purpose and Function

This Cummins part plays a role in securing and aligning various components within a truck’s system. It ensures that parts are held in place correctly, which is vital for the proper functioning of the truck. By maintaining the correct positioning of components, the clip helps in the smooth operation of the truck’s mechanical systems. Its design allows for easy attachment and detachment, facilitating maintenance and repairs 2.

Key Features

The 3031618 Clip is characterized by its robust design and durable material construction. It is made from high-strength materials to withstand the rigors of heavy-duty truck environments. The clip’s design includes features that enhance its grip and stability, ensuring that it remains securely in place under various operating conditions. These attributes contribute to its longevity and reliability in demanding applications 3.

Benefits

Using this part in truck maintenance and assembly offers several advantages. It provides improved reliability by ensuring that components are correctly aligned and secured. The ease of installation reduces downtime during maintenance procedures, making it a cost-effective solution for fleet operators. Additionally, its durable construction minimizes the need for frequent replacements, further enhancing its cost-effectiveness 4.

Installation Process

Installing the Cummins 3031618 Clip involves a straightforward procedure. First, identify the location where the clip is required. Ensure that the surface is clean and free from debris. Position the clip over the designated area and press it firmly into place. Tools such as a flathead screwdriver may be used to ensure a secure fit. Always refer to the manufacturer’s guidelines for specific instructions and any additional components required for installation 5.

Common Issues and Troubleshooting

Typical problems associated with the 3031618 Clip may include improper installation, leading to misalignment of components, or wear and tear over time. To address these issues, ensure that the clip is correctly positioned during installation. Regular inspections can help identify signs of wear early, allowing for timely replacement. Maintenance tips include keeping the clip and surrounding areas clean to prevent debris from affecting its performance 6.

Maintenance Tips

To ensure the longevity and performance of the Cummins 3031618 Clip, regular maintenance practices are recommended. Inspect the clip during routine maintenance checks for any signs of damage or wear. Clean the clip and its surrounding areas to remove any buildup that could affect its grip. Replacement intervals will depend on the operating conditions and usage, but regular inspections will help determine when a replacement is necessary 7.

Manufacturer Overview - Cummins

Cummins is a renowned company in the automotive industry, known for its commitment to quality and innovation. With a history of producing reliable and high-performance parts, Cummins has established a strong reputation among fleet operators and maintenance professionals. The company’s product range includes a variety of components designed to enhance the efficiency and reliability of heavy-duty trucks. Cummins’ dedication to excellence is evident in the design and manufacturing of parts like the 3031618 Clip 8.

Compatibility with Engine Models

The 3031618 Clip is designed to fit seamlessly within various engine models, ensuring optimal performance and reliability. This clip is engineered to meet the stringent standards required for its application across different engine types.

K38 Engines

In the K38 engine series, the Clip is integral to maintaining the structural integrity of the engine components. It is used to secure and stabilize parts, ensuring that the engine operates smoothly and efficiently. The clip’s design allows for easy installation and removal, facilitating maintenance and repair processes.

NH/NT 855 Engines

For the NH/NT 855 engines, the Clip plays a role in the engine’s operational framework. This clip is specifically engineered to fit the unique design and requirements of the NH/NT 855 engines, providing a secure hold for various components. Its precision-engineered fit ensures that the clip performs reliably under the demanding conditions these engines operate in.

Grouping by Application

The Clip is versatile and can be applied across multiple engine models within the Cummins range. Its design allows it to be used in both K38 and NH/NT 855 engines, making it a valuable component for technicians and engineers working with these engines. The clip’s compatibility with these engine models underscores its importance in maintaining the overall performance and longevity of the engines 9.

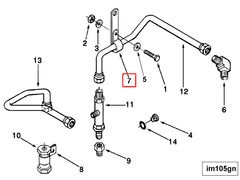

Role of Part 3031618 Clip in Engine Systems

The 3031618 Clip is instrumental in securing and maintaining the integrity of various engine components. It is utilized in the Aftercooler Plumbing Mounting to ensure that the plumbing is firmly attached, preventing any potential leaks or disconnections that could affect engine performance.

In the Air Signal system, the clip plays a role in securing the connections, ensuring that the air signals are transmitted accurately without any interruptions. This is vital for the proper functioning of the engine’s air management system.

For the EBM (Engine Bay Module) Plumbing, the clip is used to hold the plumbing in place, ensuring that the coolant or other fluids are efficiently circulated throughout the engine bay without any risk of hose detachment.

In the Air Fuel (A/F) Comp system, the clip secures the components that regulate the air-fuel mixture, which is essential for optimal combustion and engine efficiency.

The Exhaust Manifold relies on the clip to maintain the integrity of the connections, ensuring that exhaust gases are properly directed away from the engine without any leaks.

For the Fuel Supply Mounting Tube and Fuel Tubing, the clip is used to secure these components, ensuring a consistent and safe fuel supply to the engine.

In the Intake Manifold and Manifold, Exhaust, the clip helps in securing the manifold connections, which is important for the efficient intake of air and expulsion of exhaust gases.

The Manifold Press Mounting Tube, Manifold Press Tube Mounting, Manifold Pressure Tube, MFLD Pres Tube, and MFLD Press Tube all utilize the clip to ensure that the pressure tubes are securely mounted, maintaining accurate pressure readings and system integrity.

In the Mounting, Air Intake Manifold, the clip is used to secure the manifold to its mounting points, ensuring a stable and efficient air intake system.

For the Plumbing, Air Fuel Control and Plumbing, AFC, the clip secures the connections in the air fuel control system, ensuring precise control over the air-fuel mixture.

Lastly, in the Pressure Tube Manifold and Valve, Fuel Shutoff, the clip is used to secure these components, ensuring that pressure is maintained within the manifold and that the fuel shutoff valve operates correctly.

Conclusion

The Cummins 3031618 Clip is a vital component in the maintenance and operation of heavy-duty truck systems. Its robust design, ease of installation, and compatibility with various engine models make it an essential part for ensuring the reliability and efficiency of truck engines. Regular maintenance and proper installation are key to maximizing the benefits of this clip, contributing to the overall performance and longevity of the vehicle.

-

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩ -

Wright, G. (2015). Fundamentals of Medium-Heavy Duty Diesel Engines. Jones & Bartlett Learning.

↩ -

Bosch, R. (2007). Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5659685.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5659685.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5659685.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5659685.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5659685.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5659685.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.