This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

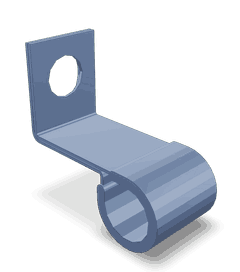

Cummins Part #3073750 Clip is a component designed for use in commercial trucks. This clip serves a specific function within the truck’s mechanical systems, contributing to the overall operation and efficiency of the vehicle. Understanding its purpose and role is fundamental for maintaining and optimizing truck performance.

Purpose and Functionality

This Cummins part is utilized in truck operations to secure various components within the vehicle’s mechanical systems. It functions by providing a stable connection between parts, ensuring they remain in place under operational conditions. This clip is integral to maintaining the structural integrity and operational efficiency of the truck’s mechanical components.

Key Features

3073750 is characterized by its robust design and material composition. Crafted from high-quality materials, it is built to withstand the rigors of commercial truck operations. Its design includes features that enhance its performance and durability, such as a precise fit and resistance to wear and corrosion. These attributes ensure the clip can endure the demanding conditions of truck use.

Benefits

Incorporating this part into a truck’s mechanical system offers several advantages. It contributes to improved mechanical stability by securely holding components in place. The clip’s design also facilitates ease of installation, reducing downtime during maintenance procedures. Furthermore, by ensuring components are properly secured, the clip plays a role in enhancing the overall efficiency of the truck.

Installation Process

Installing 3073750 requires attention to detail to ensure proper fitting. The process involves identifying the correct location for the clip, using the appropriate tools to secure it in place, and verifying that it is correctly installed. Following manufacturer guidelines during installation is important to ensure the clip functions as intended and contributes to the truck’s operational efficiency.

Maintenance and Troubleshooting

Regular maintenance of this Cummins part is important for ensuring its longevity and optimal performance. This includes periodic inspections for signs of wear or damage and replacing the clip if necessary. Common issues that may arise with the clip include loosening over time or damage from operational stress. Addressing these issues promptly can prevent more significant problems and ensure the clip continues to perform its intended function.

Compatibility and Applications

This part is designed for use in specific types of trucks and models. Its application is determined by the mechanical requirements of the truck and the specific components it is intended to secure. Using the correct clip for the intended application is important to ensure compatibility and optimal performance.

Safety Considerations

When handling and installing this Cummins part, observing safety practices is important. This includes using the appropriate personal protective equipment, following manufacturer guidelines for installation, and ensuring the work area is safe and free from hazards. Adhering to these safety considerations helps prevent accidents and ensures the integrity of the component and the truck’s mechanical system.

Cummins Corporation Overview

Cummins Corporation is a leading manufacturer in the automotive and commercial truck industry, with a history of innovation and commitment to quality. The company’s role in producing high-quality truck components, including 3073750, underscores its dedication to enhancing the performance and reliability of commercial vehicles. Cummins’ focus on quality and innovation in manufacturing ensures that its components meet the demanding requirements of the industry.1

Engine Compatibility with Part 3073750

This part, manufactured by Cummins, is designed to fit a variety of Cummins engines. Here is a breakdown of the compatibility across different engine models:

B6.7 and B153B Series

- B6.7 CM2670

- B153B

These engines, part of the B6.7 and B153B series, are typically used in medium-duty applications and are known for their robust performance and reliability. The Clip is engineered to integrate seamlessly with these engines, ensuring proper function and longevity.

ISM Series

- ISM CM570

- ISM CM876

- ISM11 CM876 SN

The ISM series engines are widely used in both on-highway and off-highway applications. The Clip is compatible with these models, providing essential support and securing various components within the engine assembly.

L10 Series

- L10 CELECT

- L10 GAS

The L10 series engines are known for their high efficiency and advanced technology. The Clip is designed to fit these engines, ensuring that all parts remain securely in place, contributing to the overall performance and durability of the engine.

M11 Series

- M11 CELECT

- M11 CELECT PLUS

- M11 MECHANICAL

The M11 series engines are versatile and used in a variety of applications, from construction to agricultural machinery. The Clip is compatible with all M11 models, providing a reliable solution for maintaining the integrity of the engine components.

QSK19 and QSM11 Series

- QSK19 CM850 MCRS

- QSM11 CM570

These engines are designed for heavy-duty applications and are known for their power and efficiency. The Clip is engineered to fit these engines, ensuring that all parts are held securely, which is crucial for the high-stress environments these engines operate in.

By ensuring compatibility with a wide range of Cummins engines, the Clip provides a reliable solution for maintaining and securing various components within these engines.

Role of Part 3073750 Clip in Engine Systems

This part is integral to the secure and efficient operation of several engine components. It ensures that wiring harnesses and plumbing lines are correctly positioned and maintained, which is essential for the overall functionality of the engine system.

Electronic Control Module Wiring Harness

In the electronic control module (ECM) wiring harness, the Clip is used to secure the harness in place. This prevents any unwanted movement that could lead to wire fatigue or disconnection, ensuring consistent signal transmission between the ECM and various sensors and actuators.

Engine Control Module

For the engine control module (ECM), the clip plays a role in maintaining the structural integrity of the connections. It helps in securing the module to its mounting point, reducing vibrations that could interfere with the ECM’s operation.

Engine Control Wiring Harness

Similar to its role in the ECM wiring harness, the Clip is employed in the engine control wiring harness to keep wires organized and protected. This is particularly important in high-vibration environments typical of engine compartments.

Flywheel Housing

In the flywheel housing, the clip is used to secure plumbing lines and electrical connections. This ensures that all components within the housing remain in their designated positions, which is vital for the proper functioning of the flywheel and its associated systems.

Flywheel Housing Plumbing

For the flywheel housing plumbing, the Clip helps in maintaining the alignment and integrity of the plumbing lines. This is essential for preventing leaks and ensuring that fluid dynamics within the system are optimal.

Radiator Plumbing

In the radiator plumbing system, the clip secures the connections between various components, such as hoses and fittings. This ensures a leak-free system and maintains the efficiency of the cooling process.

Turbocharger Arrangement

Within the turbocharger arrangement, the Clip is used to secure the turbocharger to its mounting points. This is important for maintaining the turbocharger’s alignment and reducing the risk of damage from excessive movement.

Turbocharger Mounting Kit

The clip is a key component in the turbocharger mounting kit, where it helps in securing the turbocharger to the engine. This ensures that the turbocharger operates within its designed parameters, enhancing overall engine performance.

Turbocharger Plumbing

In the turbocharger plumbing, the Clip secures the various lines and connections, ensuring that the system remains intact under the high pressures and temperatures typical of turbocharger operations.

Wiring Harness

Finally, across all wiring harnesses within the engine system, the Clip plays a vital role in keeping wires organized and protected. This is essential for maintaining the electrical integrity of the engine, ensuring reliable communication between all electronic components.

Conclusion

Understanding the role and importance of Cummins Part #3073750 Clip in commercial trucks is essential for maintaining and optimizing truck performance. Its robust design, ease of installation, and compatibility with various Cummins engines make it a critical component in ensuring the structural integrity and operational efficiency of truck mechanical systems. Regular maintenance and adherence to safety practices during installation are important to ensure the longevity and optimal performance of this part.

-

Cummins Corporation. (n.d.). About Cummins. Retrieved from https://www.cummins.com/about

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.