This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

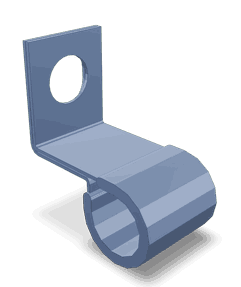

The Cummins 3161585 Clip is a component utilized in the operation of commercial trucks. It serves a specific function within the truck’s system, contributing to the overall efficiency and reliability of the vehicle. Cummins Inc., a well-established manufacturer in the commercial truck industry, produces this clip as part of its extensive range of automotive parts 1.

Purpose and Function

This Cummins part plays a role in securing and maintaining the integrity of certain connections within a truck’s component system. It ensures that parts remain firmly in place, which is vital for the proper functioning of the truck. The clip operates by providing a stable attachment point, which helps in the secure assembly of various truck components 2.

Key Features

The 3161585 is constructed from durable materials, ensuring it can withstand the rigors of commercial truck operations. Its design includes specific elements that enhance its functionality, such as a precise fit and robust construction. Unique characteristics of the clip may include anti-corrosive coatings or specialized shapes that facilitate easy installation and removal 3.

Benefits

The advantages of the 3161585 include its durability, which contributes to the longevity of the truck’s components. It is designed for ease of installation, reducing downtime during maintenance procedures. Additionally, the clip’s secure fit enhances the overall performance and safety of the truck by ensuring that connections remain intact under various operating conditions.

Installation Process

To install the Clip, begin by identifying the correct location on the truck where the clip is required. Use the appropriate tools to place the clip in position, ensuring it is aligned correctly with the components it is intended to secure. Follow the manufacturer’s guidelines for tightening and securing the clip to avoid over-tightening, which could damage the clip or the components it is attaching.

Common Issues and Troubleshooting

Common problems with the 3161585 may include wear and tear from frequent use or improper installation. If the clip appears damaged or does not secure the components as intended, it may need to be replaced. Troubleshooting involves inspecting the clip for signs of damage, ensuring it is correctly installed, and verifying that it is the appropriate size and type for the application.

Maintenance Tips

Regular maintenance of the 3161585 involves periodic inspection to check for signs of wear or damage. Cleaning the clip and its surrounding area can prevent the buildup of debris that may affect its performance. Following the manufacturer’s recommended inspection intervals will help ensure the clip continues to function effectively.

Replacement Guidelines

The 3161585 should be replaced if there are visible signs of damage, such as cracks or deformation, or if it no longer secures the components as intended. The replacement process involves removing the old clip, inspecting the area for any damage, and installing a new clip according to the manufacturer’s instructions to maintain the integrity of the truck’s component system.

Engine Compatibility

This part is designed to be compatible with several engine models. It is a crucial component in ensuring the proper functioning and longevity of the engine by securing various parts in place. Below is a detailed description of how this part fits into the specified engines.

M11 CELECT PLUS and M11 MECHANICAL Engines

The 3161585 is engineered to fit seamlessly within the M11 CELECT PLUS and M11 MECHANICAL engines. These engines are known for their robust design and efficiency, and the clip plays a vital role in maintaining their structural integrity.

-

M11 CELECT PLUS Engine: This engine variant is equipped with advanced electronic controls that enhance performance and efficiency. The clip is strategically placed to secure components that are critical for the electronic systems’ operation, ensuring that all parts remain firmly in position under various operational conditions.

-

M11 MECHANICAL Engine: In the M11 MECHANICAL engine, the clip is used to hold together parts that are essential for the mechanical operation of the engine. This includes securing components that are subject to high stress and vibrations, thereby preventing any potential loosening or misalignment that could affect engine performance.

Both engine variants benefit from the clip’s design, which ensures that it can withstand the operational demands placed on it. The clip’s material and construction are specifically chosen to provide durability and reliability, making it an indispensable part of the engine’s assembly.

Role of Part 3161585 in Engine Systems

The 3161585 is an essential component in the assembly and functionality of various engine systems. Its primary role is to secure and maintain the integrity of connections within these systems, ensuring optimal performance and reliability.

Injector Systems

In injector systems, the 3161585 is used to secure the injector to its mounting point. This ensures that the injector remains firmly in place, allowing for precise fuel delivery. The clip helps in maintaining the alignment of the injector, which is vital for consistent fuel spray patterns and efficient combustion. Additionally, it prevents any unwanted movement that could lead to fuel leaks or inefficient fuel delivery.

Injector Plumbing

For injector plumbing, the 3161585 plays a significant role in securing the connections between the fuel lines and the injectors. This is important for maintaining the integrity of the fuel delivery system. The clip ensures that there are no loose connections, which could result in fuel leaks or inconsistent fuel pressure. It also helps in preventing vibrations from affecting the fuel lines, thus ensuring a stable fuel supply to the injectors.

Oil Control Valve (OCV) Systems

In Oil Control Valve (OCV) systems, the 3161585 is used to secure the OCV to its mounting location. This is important for the precise control of oil flow within the engine. The clip ensures that the OCV remains securely attached, allowing it to function correctly in regulating oil pressure and flow. This, in turn, helps in maintaining optimal engine performance and efficiency.

Performance Parts

When it comes to performance parts, the 3161585 is often used to secure various components that are critical to enhancing engine performance. Whether it’s securing high-flow injectors, performance fuel lines, or other aftermarket parts, the clip ensures that these components remain in place and function as intended. This is particularly important in high-performance applications where even minor component movement can affect overall engine performance.

General Parts

In general engine parts, the 3161585 is used across a variety of applications to secure components and ensure they function correctly. From securing sensors to mounting brackets, the clip plays a vital role in maintaining the structural integrity and functionality of these parts. This helps in ensuring that all engine components work together seamlessly, contributing to the overall performance and reliability of the engine.

Conclusion

The Cummins 3161585 Clip is a vital component in the maintenance and operation of commercial trucks and their engines. Its role in securing various parts ensures the integrity and efficiency of the truck’s systems. Regular maintenance and proper installation are key to maximizing the benefits of this part, contributing to the overall performance and reliability of the vehicle.

-

Hilgers, Michael. Alternative Powertrains and Extensions to the Conventional Powertrain. Springer Nature, 2023.

↩ -

Hiereth, Hermann, Peter Prenninger, and Klaus W Drexl. Charging the Internal Combustion Engine. Springer, 2010.

↩ -

Huzij, Robert, Angelo Spano, and Sean Bennett. Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning, 2019.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.