This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

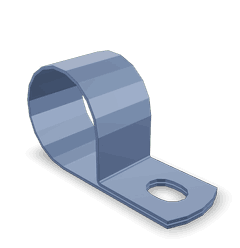

The Cummins 3200706 Clip is a specialized component designed for use in commercial truck operations. It serves a specific function within the engine system, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and role is fundamental for maintaining and optimizing truck performance.

Basic Concepts Related to Clips

Clips are mechanical fasteners used to secure components in various systems. They function by holding parts in place, preventing movement, and ensuring proper alignment. In automotive and heavy-duty applications, clips are essential for maintaining the integrity of assemblies and ensuring that components operate as intended 1.

Purpose of the 3200706 Clip

This Cummins part plays a role in securing specific components within the Cummins engine system. Its application ensures that parts remain in the correct position, which is vital for the engine’s operation. This clip is integral to maintaining the structural integrity and functional alignment of engine components, thereby supporting the engine’s performance and longevity 2.

Key Features

The 3200706 Clip is characterized by several key features that enhance its functionality. It is typically made from durable materials to withstand the rigors of commercial truck environments. The design of the clip includes precise dimensions and a secure fitting mechanism, ensuring it can effectively hold components in place under various operating conditions 3.

Benefits

The advantages provided by the 3200706 Clip include improved reliability of the engine system, ease of installation, and contribution to overall system efficiency. By securely holding components in place, it helps prevent issues that could arise from part misalignment or movement. Additionally, its design allows for straightforward installation, reducing downtime during maintenance procedures 4.

Installation Process

Proper installation of the 3200706 Clip involves several steps to ensure correct fitting. Begin by identifying the location where the clip is required. Use the appropriate tools to position the clip over the designated components. Ensure that the clip is fully engaged and securely in place. Following manufacturer guidelines during installation will help maintain the clip’s effectiveness and durability.

Common Issues and Troubleshooting

Typical problems that may arise with the 3200706 Clip include corrosion or improper fitting. Corrosion can be addressed by cleaning the affected area and applying a protective coating. If the clip does not fit correctly, verify that it is the correct size and type for the application, and ensure that all components are properly aligned before securing the clip.

Maintenance Tips

Regular maintenance checks are recommended to prolong the lifespan and ensure the continued effective performance of the 3200706 Clip. Inspect the clip during routine engine maintenance for signs of wear, corrosion, or damage. Cleaning the clip and its surrounding area can prevent buildup that might affect its function. Additionally, ensuring that all secured components remain in proper alignment will help maintain the clip’s effectiveness.

Replacement Guidelines

When replacing the 3200706 Clip, look for signs of wear, such as cracks or significant corrosion, which indicate it may no longer be effective. To replace the clip, carefully remove it from the components, taking note of its orientation and fit. Install the new clip following the same steps used for the initial installation, ensuring it is securely in place and properly aligned with the components it is designed to hold.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance engines. The company’s product range includes a variety of engine sizes and configurations, designed to meet the diverse needs of commercial transportation.

Compatibility with Engine Models

The 3200706 Clip is designed to fit seamlessly with several engine models, ensuring reliable performance and durability. This clip is a critical component in maintaining the integrity of the engine’s operational systems.

K19 Engines

The K19 engine series benefits from the precise fit of the 3200706 Clip, which is engineered to handle the specific demands of this engine model. The clip’s design ensures it can withstand the operational stresses and maintain the alignment of various engine components.

QSK19 CM500 and QSK19G Engines

For the QSK19 CM500 and QSK19G engines, the 3200706 Clip plays a crucial role in the engine’s assembly. These engines, known for their robust performance, require components that can endure high operational loads. The clip’s compatibility with these models ensures that the engine’s parts remain securely fastened, contributing to the overall efficiency and longevity of the engine.

Grouping of Engine Models

The QSK19 CM500 and QSK19G engines share many design similarities, which is why the 3200706 Clip is compatible with both. This compatibility allows for streamlined maintenance and repair processes, as technicians can use the same part across multiple engine models within this group. The clip’s design is tailored to meet the specific needs of these engines, ensuring optimal performance and reliability.

Role of 3200706 Clip in Engine Systems

The 3200706 Clip is an essential component in the assembly and maintenance of various engine systems. It facilitates the secure attachment and alignment of multiple components, ensuring the efficient operation of the engine. Here’s how the 3200706 Clip integrates with the provided components:

-

Kit and Overhaul Kit: The clip is used within these kits to ensure that all components are correctly aligned and fastened during the overhaul process. This helps in maintaining the structural integrity and performance of the engine.

-

PDC (Power Distribution Center): In the assembly of the PDC, the 3200706 Clip helps in securing electrical connections and components, ensuring a stable and reliable power distribution system.

-

Lubricating Oil Scavenge Pump and Scavenge Pump: The clip plays a role in attaching the scavenge pump to its mounting points, ensuring it operates efficiently by maintaining proper alignment and reducing the risk of leaks.

-

Lubricating Oil Suction Mounting and Lubricating Oil Suction Tube Mounting: These components rely on the clip to secure the suction tubes and mountings, ensuring a consistent flow of lubricating oil to critical engine parts.

-

Lubricating Oil Tube and Lubricating Suction Tube: The clip is instrumental in attaching these tubes to their respective mounts, facilitating the smooth transfer of lubricating oil throughout the engine.

-

Mounting Tube L.O and Mounting Tube Oil Suction: These tubes are secured using the clip, ensuring they remain in place and function correctly within the engine’s lubrication system.

-

Oil Filler Tube Mounting: The clip assists in attaching the oil filler tube to its mounting, ensuring easy and secure access for oil changes and maintenance.

-

Oil Pan: During the installation of the oil pan, the clip helps in securing it to the engine block, ensuring a leak-free seal and proper containment of lubricating oil.

-

Oil Supply Tube: The clip is used to fasten the oil supply tube, guaranteeing a reliable supply of oil to various engine components.

-

Water Outlet and Water Outlet Conn: These components are secured using the clip to ensure efficient coolant flow and prevent leaks in the engine’s cooling system.

-

Water Tube Support: The clip helps in attaching the water tube support, maintaining the structural integrity of the coolant system and ensuring consistent coolant distribution.

-

Tube Brace, Tube Lubricating Oil Suction Mounting, and Tube Oil Suction Mounting: These components rely on the clip for secure attachment, ensuring the stability and efficiency of the lubricating oil system.

By integrating the 3200706 Clip into these engine systems, mechanics and engineers can ensure that all components are properly aligned, securely fastened, and functioning optimally, contributing to the overall performance and longevity of the engine.

Conclusion

The Cummins 3200706 Clip is a vital component in the maintenance and operation of commercial truck engines. Its role in securing and aligning various engine components ensures the efficient and reliable performance of the engine. Proper installation, regular maintenance, and timely replacement of this part are essential for maintaining the integrity and longevity of the engine system.

-

Dixon, John C. Tyres Suspension and Handling Second Edition. SAE International, 1996.

↩ -

Aird, Forbes. Bosch Fuel Injection Systems. HP Books, 2001.

↩ -

Rajamani, Rajesh. Vehicle Dynamics and Control. Springer, 2005.

↩ -

Zhao, Hua. Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.